I'm new to Arduino, and programing in C+, but not programing in general. This is my first project, and am looking for feedback from a more experienced audience. So here goes:

I set out to create a closed loop boost controller for a automotive application, those of you not familiar this the concept this is a rough description, the controller essentially pulses a solenoid valve installed inline on the vacuum/boost hose from the turbocharger to the wastegate. It is intended to "hide" boost from the wastegate to keep it closed, which in turn builds more boost.

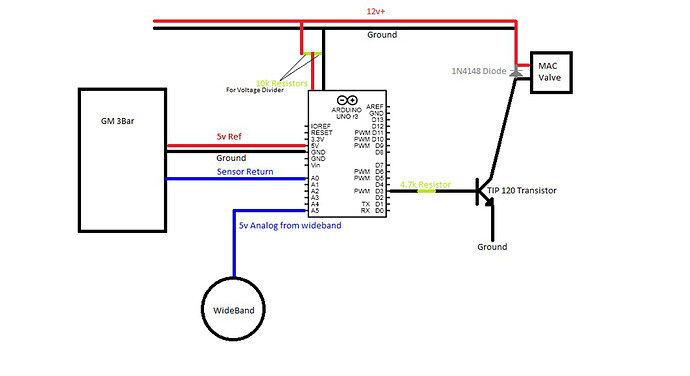

My Diagram is attached, and it seems to work on the desk, I have not installed it in a car yet. Mostly I'm curious about the quality of my code, is this the cleanest most efficient way to write it? Does anyone have suggestions on how to improve it?

#include <PID_v1.h>

//Define Pins used

const int MapPin = A0; // Map sesnor pin

const int MacPin = 3; // Mac valve pin

const int WBPin = A5; // Wideband pin

//Set desired boost level and define Pid variables

double TargetBoost = 250; // 250kpa is target boost level

double MapKPA, PidPWM;// Initialise other PID variables

const long sampleRate = 15;// Pid sample rate

// Pid tuning parameters

const double Kp = 7; //Pid Proporional Gain. Initial ramp up i.e Spool, Lower if over boost

const double Ki = 20; //Pid Integral Gain. Overall change while near Target Boost, higher value means less change, possible boost spikes

const double Kd = 0; //Pid Derivative Gain. Not Sure what to do with it.....

//Load PID controller

PID myPID(&MapKPA, &PidPWM, &TargetBoost, Kp, Ki, Kd, DIRECT); //Initialize PID with our variables

//Set other global variables

unsigned long LeanTime;

float Lean = 0;

float Cut = 0;

float AF = 0;

float Atmo = 0;

void setup() {

//Serial.begin(9600); //debug uncomment to debug

Atmo = analogRead(MapPin) * (315.0 / 1023.0); //Read Atmospheric pressure and convert to KPA

//Pid Stuffs

myPID.SetMode(AUTOMATIC);

myPID.SetOutputLimits(0, 180); //Mac valve lower duty cycle limits 180 Closed, 0 Off

myPID.SetSampleTime(sampleRate); //PID's sample rate in milliseconds

TCCR2B = TCCR2B & B11111000 | B00000111; //Set pin 3 and 11 PWM frequency to 31hz

pinMode(13, OUTPUT);

}

void loop() {

//BenchTest

/*if (MapKPA < TargetBoost) {

MapKPA = (MapKPA + random(10));

}

else {

MapKPA = (MapKPA - (100.0 - PidPWM));

}*/

MapKPA = analogRead(MapPin) * (315.0 / 1023.0); //Read map Pin and convert to KPA

AF = ((analogRead(WBPin) * (5.0 / 1023.0)/0.625) + 10.0);//Read wideband and convert to a/f ratio

if (AF > 12.1) {

Lean = Lean + 1; //add to lean counter

}

else {

Lean = 0;//Reset lean counter becuase rich

}

if (Lean == 1) {

LeanTime = millis();//Log initial lean reading time

}

if (((Lean >= 2)) && ((unsigned long)(millis() - LeanTime) > 250)) {//Check if lean for more than 250ms (.25 seconds) and lean more than 2 loops

Cut = 1; //cut boost if too lean for too long

}

else {

Cut = 0; //dont cut boost becuase rich :D

}

if ((MapKPA < 100) || (Cut>0)) {//Keep valve from clicking when not in boost or cut boost if too lean

PidPWM = 0;//Dont pulse if not building boost or wideband is lean

//Serial.print("Boost Cut");//debug

digitalWrite(13, HIGH);

}

else {

myPID.Compute(); //Execute Pid and produce a pulse width if above 100kpa and not lean

digitalWrite(13, LOW);

}

analogWrite(MacPin, PidPWM); //Energize mac valve

/*

//--------------------Debug--------------------

Serial.print("--------------------PW=");

Serial.println(PidPWM);

Serial.print("--------KPA=");

Serial.println(MapKPA);

Serial.print("Target=");

Serial.println(TargetBoost);

Serial.print("AF=");

Serial.println(AF);

Serial.print("Cut=");

Serial.println(Cut);

Serial.print("Lean=");

Serial.println(Lean);

Serial.print("LeanTime=");

Serial.println(LeanTime);

Serial.println(" ");

delay(250);*/

}