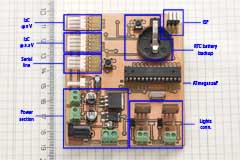

Let's start with the controller board...

(Click on the thumbnail to see full size.)

The power section takes 12 V as input which is needed for lights. Reduced to 5 V and 3.3 V for other components, available via screw terminals as well for future use.

Serial line and ISP - I found comfortable to use UNO board with removed 328, wired to my boards for serial communication when debugging instead of having USB/serial adapter. ISP, no comment.

I2C lines - pulled up to 5 V and 3.3 V for used ICs, common logic level converter with MOSFETs used.

Lights outputs - screw terminals to connect LED lights. Switched by MOSFETs driven by PWM output from 328.

ATmega328P - running at 16 MHz, standard standalone wiring, reset button. Left unpopulated soldering pads next to IC holder for future use.

Battery - power backup for RTC IC, with IC reset button.

(Click on the thumbnail to see full size.)

DS3231 - real time clock IC. I prefered this one to DS1307 for this project because of the precision.

555 - operating in astable multivibrator mode to drive a piezo buzzer. I prefered this to use tone() & delay() combo.

As you can see I use home made PCBs. To be honest, I have never used any PCB fabrication service for my DIY home projects - never had a good reason for it. I tuned my PCB creation and I can safely go down to 0.2 mm tracks. You can see I place SMD components at bottom layer. Reason is obvious - to minimize via count. I leave as much copper on board as possible/reasonable to save etching solution. I usualy use UV curable solder mask from eBay as well but I just ran out of it. Many damn it - I believe they don't know how to work with it. Results are very nice when you master the procedure. No silk screen so far, just etched text/symbols. It takes less than hour to make etched double sided PCB, measured from template printing. You can calculate the costs.

More to come...