Hello,

I am using a Toshiba TG6549PG H-Bridge to control a 12v DC motor. The reason I went for the TG6549 is because it can handle about 3.5A steady (The motor in it's application would draw around 2.5A).

Here is the datasheet http://www.toshiba.com/taec/components2/Datasheet_Sync/261/3626.pdf

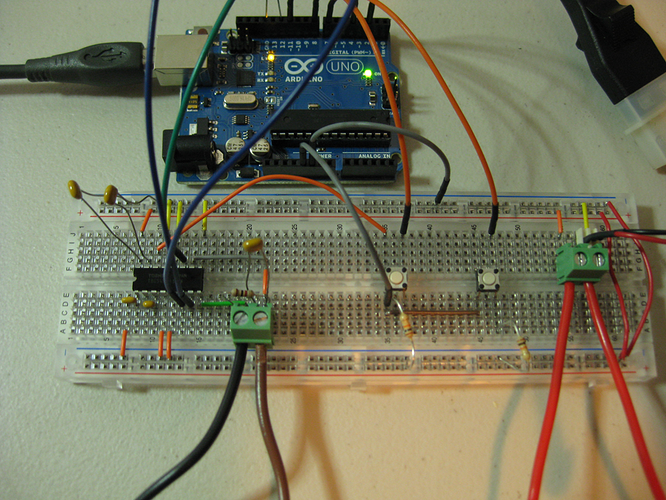

I've run in to the following issues: I have full speed/power in one direction, and very little in the other. The H-Bridge uses four pins, one for standby, one for PWM to control the speed and one for each direction. I have connected the H-Bridge according to the typical application outlined in the datasheet for 12v Vcc, with arduino pins 2 & 4 going to IN1 and IN2, arduino pin ~11 to PWM on the TG6549. I have two buttons, one is for full-speed CW, the other full-speed CCW.

From what I can tell, there is something wrong with my code or the arduino board itself (though I tried it out with an UNO and a MEGA), or maybe the connections yet. I tried the H-Bridge manually, supplying 5V and GND from the arduino and trying the buttons w/ their pulldown resistors directly to the IN1 and IN2 pins, and tied the PWM and SB pins to 5v as well and I get full speed in each direction no problem. That's why I figure its my code... anyways here it is, it's probably a rookie mistake...

//Toshiba TB6549PG Motor Driver Test

//PINOUT

//Input

const int ctrlFwdPin = 7; //0-5v Signal to Arduino Pin 50

const int ctrlRevPin = 8; //0-5v Signal to Arduino Pin 52

//Output

const int fwdSig = 2; //0-5v Signal to in1 pin on Driver

const int revSig = 4; //0-5v Signal to in2 pin on Driver

const int pwmSig = 11; //PWM Signal to PWM pin on Driver

//const int sbSig = 25; //0-5v Signal to SB(Stanby) pin on Driver

//Variables

int ctrlFwdStat = 0;

int ctrlRevStat = 0;

void setup() {

//Pin Setup

pinMode(ctrlFwdPin, INPUT);

pinMode(ctrlRevPin, INPUT);

pinMode(fwdSig, OUTPUT);

pinMode(revSig, OUTPUT);

//pinMode(sbSig, OUTPUT);

pinMode(12, OUTPUT);

}

void loop() {

ctrlFwdStat = digitalRead(ctrlFwdPin);

ctrlRevStat = digitalRead(ctrlRevPin);

if(ctrlFwdStat == HIGH) {

digitalWrite(12, HIGH);

analogWrite(pwmSig, 255);

digitalWrite(revSig, LOW);

digitalWrite(fwdSig, HIGH);

}

if(ctrlRevStat == HIGH) {

digitalWrite(12, HIGH);

analogWrite(pwmSig, 255);

digitalWrite(fwdSig, LOW);

digitalWrite(revSig, HIGH);

}

else {

digitalWrite(12, LOW);

//digitalWrite(sbSig, HIGH);

digitalWrite(pwmSig, HIGH);

digitalWrite(revSig, HIGH);

digitalWrite(fwdSig, HIGH);

}

}

Right now I have the SB pin tied to 5V and commented it out in my code just to see if that made a difference. The best results I get is if I set IN1 & IN2 high (short stop) in the else() statement and then in the direction that has trouble I get some movement, but not much. It doesn't seem to matter if I give it a PWM signal, it will move proportionally slower. Maybe I have to set the the PWM frequency? (which I have no idea where to start).

Thanks in advance!