Hello everyone,

firstly let me apologise for my ignorance surrounding electronics, I'm an emerging experiences software engineer and to be quite frank, electronics has always been something I would ask my brother.. BUT he is useless. so.. I come asking advice on how I would implement the following situation.

I have to data log over an 8 hour period 50 Treadmill motors (Treadmills are Healthstream elite ESTM5 with the motor being a DC MOTOR 2.5HP Max speed is 22km/ph) and count each revolution from the motor as a pulse (this is where it gets hairy) and the anduino can then either A) store the value onto its removable flash or send a 8byte (64bit) array to some software that i will have reading in the signal via USB or hopefully using the Ethernet port on the Ethernet Mega that I have in my hand.

A few things I am not 100% sure how works, or how will work by design and that is, does a DC motor for treadmills have a data output for retrieve information from, and if so is this an analog or digital signal. Ideally I though i would need (if i was going the 8byte out to some software) that it would give me the following:

0ms 255-255-255-255-255-255-255-255 (no rotation pulses)

500ms 255-254-255-255-255-254 -255-255 (2 treadmills send a pulse)

501ms 255-255-255-255-255-255 -255-255 (all off again)

etc. etc.

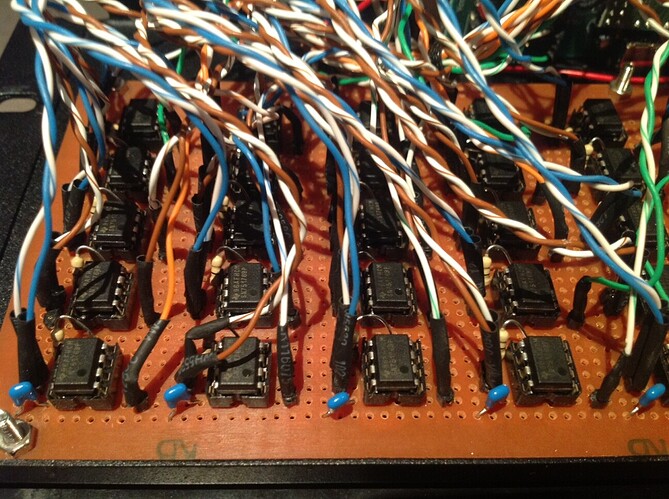

The current failing system is using a IOWarrior56 which is connected to a Ethernet Rack panel, which via USB reads the inputs of the treadmills via a small timing device similar (attached in image) that are connected to the treadmills and then wired into the Ethernet Rack. I believe there is a RS485 chip in the same module as the IOWarrior and the timing devices also have one as well. guessing the communication is then done by serial.

im quite happy to blow away the previous system as it is not performing, and I was hoping I could buy some sort of motor sensor (if the motors dont already have one) that will work well with the anduino, but anyones advice on what componentry/and or what methodology i need to get the most accurate pulses correctly concurrently over 50 treadmills would be amazing.

Sorry for the huge question, and hopefully someone is happy to help me out. My main headfritz at the moment is the best way of communicating from a treadmill motor (reading the rotations, not driving the motor) into a IO stream for me to capture the date. From there I am fine.

P.S if there is anyone in Melbourne Australia or Sydney Australia, who can help out with this issue, please respond back, as I am happy to pay for hands on advice/actual building of the system.

Thanks Robbie