Xephius:

Back on that Paul, would it be more typical to connect the DB15 ground pin to GROUND and the Arduino side to COM? Would that in effect isolate the DB15 from the Arduino? Hope these are appropriate questions here.

Sorry, that is not making much sense. We seriously need a proper diagram of how you intend to use the "DB15 cable" to connect your tally lights. Using either a ULN chip or a TPIC6B595 will provide good isolation from the Arduino - if wired properly.

Xephius:

To use relays with Arduino in Tally light you must invert status High with status Low.

To do that in Standard Firmata, you must change the function: writePort(port, (byte)value, pinWriteMask); with this: writePort(port, ((byte)value)^0xFF, pinWriteMask); (the bit are inverted with XOR).

That would be one way to do it, but there probably is a "bit invert" function in the language as well to the same effect.

There is a lot of confusion here. You are posting "snippets". The peculiar code to which PaulRB commented

PaulRB:

I am beginning to see what you mean. That code is using direct port manipulation. Who knows why, but there it is. Changing that may not be easy or risk free.

... indicates nothing more than a clumsy, almost certainly automated translation from the Firmata code you just cited. It is not difficult to do it properly and we are prepared to assist (well, I am!) but as always, we need the actual code to work with. Please either post it all here, or at the very least cite the source URL - I cannot readily find it among the links you have offered so far.

Not didactically cited, but part of the necessary explanation, I presume the "interface" from which you are controlling this is a PC to which the Arduino is connected by USB. As such we can be reassured that there are no other encumbrances on the Arduino at this point (that is, nothing else to be connected or controlled) so that PaulRB's concern about "risk free" is moot and the actual code can be massively cleaned up from the Firmata kludge.

Oh, and a final observation:

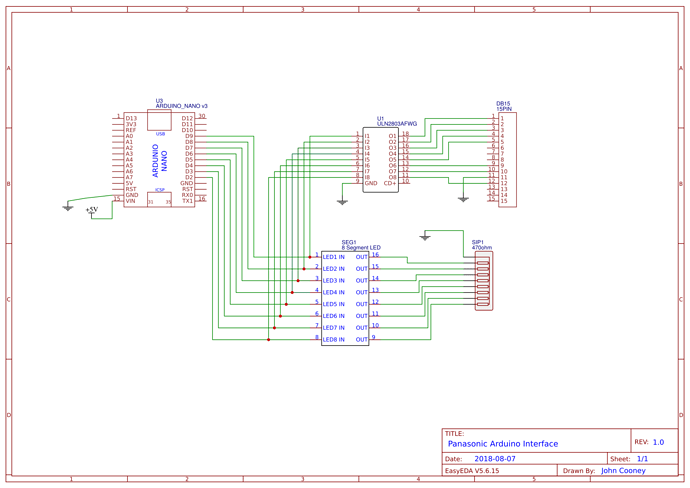

As I am prone to mention, the UNO and its shields are in general, more of a "demonstration" system than practical. Your final version would be more robust using a Nano and the interface chip mounted on a soldered perfboard.

If Firmata worked via WiFi, you could use these modules with ESP-01s at each tally light location and avoid the cabling.