EDIT:This code is DONE!

Hi, I've been into BGA rework for couple years now and finally getting into designing my own rework station. I know I could buy PID's and slap them in but that kind of takes the fun out of it for me and this will be more useful to other DIY guys and I as well. If it works the way I think it will I want to have PCB's/shields or whatever made up for other DIY guys doing the same thing. Using Brett's PID library of course(awesome btw).

I'm looking for good arduino guys to chat with regarding my project.

Some of you may be familiar with rocketscream oven reflow controller shield. Here's the code: Reflow-Oven-Controller/reflowOvenController.ino at master · rocketscream/Reflow-Oven-Controller · GitHub The osPID code is a little harder for me to read..

What I'm trying to do is somewhat similar but there will be 2 PID loops(bottom heater and top heater). In the rocketscream code, its setup for preheat, soak, reflow, cool for steps basically. I'd like the number of steps for top heater PID , target temps for each step, and dwell time for each step controlled by user input and profiles actually saved in eeprom. For bottom heater just one setpoint is ok.

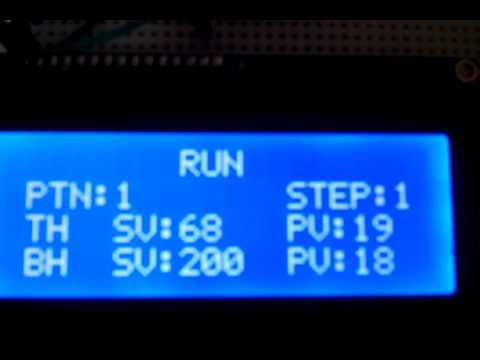

LCD setup kinda like this 20x4:

PTN:1 STEP: 1 (status here run/stop)

TH SV:225 PV 220

BH SV:200 PV 200

Of course with start/stop, up/down/left/right buttons with menu to edit profiles. Editing profiles from PC with frontend(curve plotting etc)as well.

I have my code setup so far just with one setpoint(hardcoded) and PID is working flawlessly. My idea being a noob was to get that working then slowly add other functions/features as I go so I can learn how to do everything. I don't need someone to do all the work or anything but maybe chatting about the best way to go about certain problems I'm having without clogging up the forum.

If you would like to help me it would be very much appreciated. There is potential for money here but honestly not much and will be a long time... osPID is cool but this would be much better for a rework station I think.

I'm on facebook and we could chat there or wherever else if you like.

Thanks alot for reading all this.

-Mark