I have develop a computerize loom from scratch, made with a Venetian blind and 16 servo motors that move the shafts to define the design of the weave.

you can see the Loom at

I am using the following sketch to move the servos using serial monitor and imputing by hand the values to move the servos

the following sample is for three servos but I will be using the same for 16 servos

#include <Servo.h>

String readString, servo1, servo2, servo3;

Servo myservo1; // create servo object to control a servo

Servo myservo2;

Servo myservo3;

void setup() {

Serial.begin(9600);

myservo1.attach(1); //the pin for the servo control

myservo2.attach(2);

myservo3.attach(3);

}

void loop() {}

void serialEvent() {

while (Serial.available()) {

delay(2);

if (Serial.available() >0) {

char c = Serial.read(); //gets one byte from serial buffer

readString += c; //makes the string readString

}

}

if (readString.length() >0) {

Serial.println(readString); //see what was received

// expect a string like 07002100 containing the two servo positions

servo1 = readString.substring(0, 2); //get the first two characters

servo2 = readString.substring(2, 4); //get the next two characters

servo3 = readString.substring(4, 6);

Serial.println(servo1); //print ot serial monitor to see results

Serial.println(servo2);

Serial.println(servo3);

int n1; //declare as number

int n2;

int n3;

char carray1[6]; //magic needed to convert string to a number

servo1.toCharArray(carray1, sizeof(carray1));

n1 = atoi(carray1);

char carray2[6];

servo2.toCharArray(carray2, sizeof(carray2));

n2 = atoi(carray2);

char carray3[6];

servo3.toCharArray(carray3, sizeof(carray3));

n3 = atoi(carray3);

myservo1.write(n1); //set servo position

myservo2.write(n2);

myservo3.write(n3);

readString=""; will read the next string

}

}

So if I imput and enter in the serial monitor;

000000 the three motors will move to position 0 degrees

if I imput:

001500 the second motor will rotate 15 degrees the other 2 will stay at 0

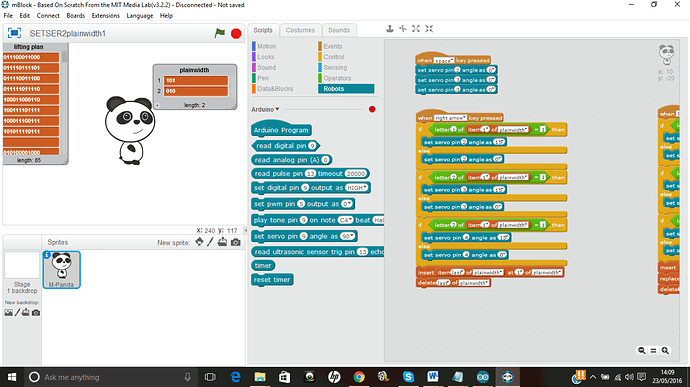

One of the more simple weaves it is called "plain width" and will need to repeat only two sequences to be completed:

sequence 1; 001500

sequence 2: 150015

Question?

How and where can I store these two sequences so when I press enter in the serial monitor takes and executes the first sequence only, if I press again enter will take and execute the second sequence, and if I press enter again would go backwards and execute the first sequence, and so on.

I have been looking at serial monitor tutorials and how to read text files and upload them to the Arduino as I will be working with more complicated and long sequences of numbers.

I come from a design background and, to be honest, I am finding it difficult to understand and apply some of the codes that I have seen browsing the subject. I do not know where the sequences could be store, how to store them in the buffer, how to let the serial monitor know the number of characters that i want to upload every time I press enter, how can I go forward or backwards through the sequences

I will really appreciate some help

Thanks