Hi all

We are constantly having "load shedding" in our country, where the sole power supplier cuts the mains power to different areas almost daily, for 2 hours at a time. ( Long story as to why and what public opinion is about this, but not relevant for this post )

It has been proven that the voltage of the mains supply, when restored by the supplier, is very erratic for quite some time after.

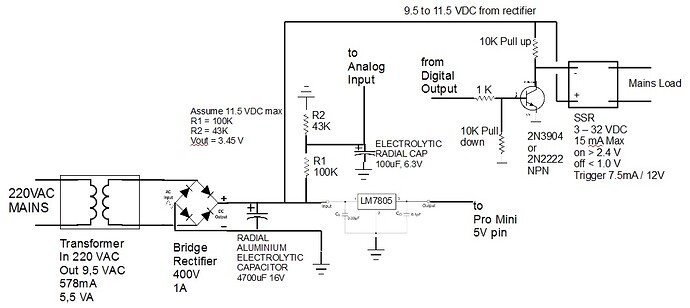

To avoid this 'dirty power' from damaging certain home office equipment, I am wanting to use a Pro Mini to do the following when the power is restored :

- check that the mains supply is above a certain voltage, and reasonable stable.

- control the restoration of the mains power to the equipment using an SSR ( pre-set time delay, say 15 minutes )

Phase two of the project will be the option to specify the time to wait, after mains power has stabilized, before restoring power to equipment ( in 5 minute increments )

Phase 3 will be to add a small ethernet module, and link to the existing DIY home automation and control system.

So the initial requirement is 2 part :

1 - measure the mains voltage

2 - control the SSR

I would be grateful if anyone could please look at the attached drawing, and comment if you think I may have missed something.

My calculations on the voltage divider are :

12 VDC = 3.837 V to analog input pin

8 VDC = 2.558 V