We have all used solder wick to remove excess solder from electronic component leads.

By reversing the process, you can use solder wick to apply a controlled amount of solder to small fine pitch components.

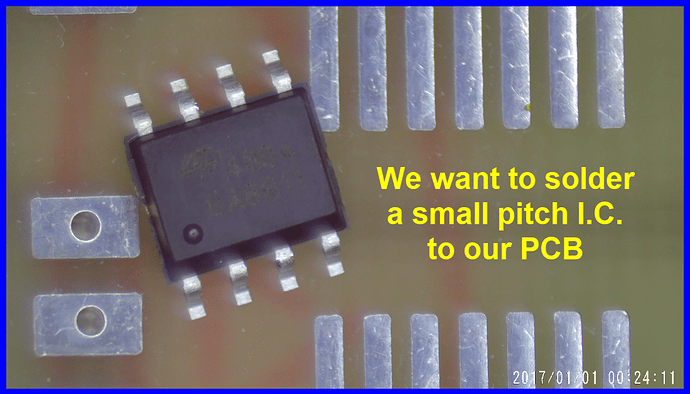

Use a magnetic hold down tool to anchor your component to the PCB.

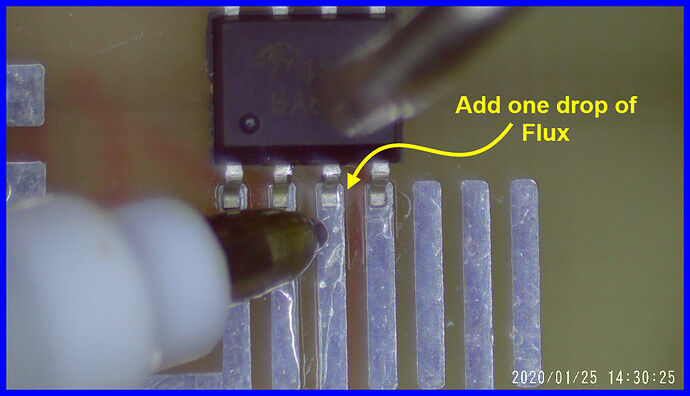

Add a drop of liquid flux to the leads.

Melt a ‘small’ blob of solder on the end of a piece of solder wick; small being the operative word.

Add a drop of liquid flux to the blob, heat with a soldering iron.

When the blob melts, slowly drag/pull the solder wick blob over the component leads; the leads take only the amount of solder they need.

Add more solder to the end of the solder wick as needed.

Experiment with different widths of solder wick to see what works best for you; 2mm wide wick is used in these images.

Going to refer to this from now on as the: SW2 soldering technique (SolderWick/SolderWave). ![]()

Melt the blob, pull the wick over the leads.