Hey!Now I know this forum is a place of free speech,really one, I love it.

We can share our experiences and learning a lot here.

My name is Wen Jia Deng, you can call me Andy.I have over 10 years' experiences working for PCB Factories in China. I started as CAM/CAD engineer then Marketing sales,then I worked as Marketing manager.I am very familiar with the manufacturing process and marketing price of PCBs.

And I am also well known about PCBs markets in China,have very good connections with a variety of factories here.

I have knowledge of your different demands and requests on PCBs -

as prototypes, medium and large quantities,simple and complex circuits,rigid,flex and rigid-flex circuits.

I would like to answer all kinds of questions concerning PCB manufacturing here, share my experiences and give suggestions while you want to design or buy PCBs.

The last day also working day of 2019.

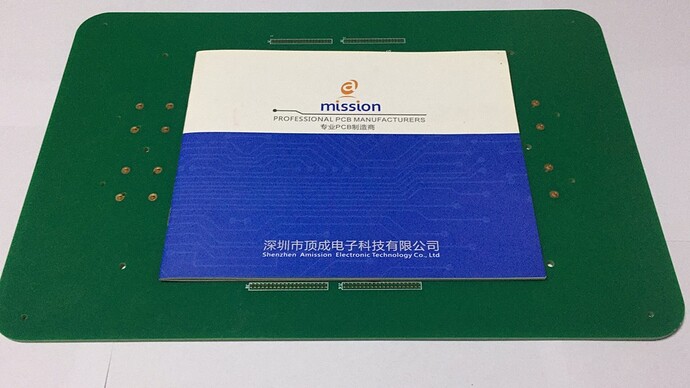

We've finished a 4 layer PCB with 6.35mm thickness.

It's a great improvement of our capability.

Section ratio is beyond 14:1(min.via 0.45)

Might I make some simple suggestions.

Posting tips.

- Always list the version of the IDE you are using and the board version if applicable.

- How to insert an image into your post. ( Thanks Robin2 )

- Add your sketch where applicable but please use CODE TAGS ( </> )

- Add a SCHEMATIC were needed even if it is hand drawn

- Add working links to any specific hardware as needed (NOT links to similar items)

- Guessing is not the best way to describe an issue. Actual facts are the most important.

- Remember that the people trying to help cannot see your problem so give as much information as you can

Bob.