// PZEM-017 DC Energy Meter with LCD By Solarduino

// Note Summary

// Note : Safety is very important when dealing with electricity. We take no responsibilities while you do it at your own risk.

// Note : This DC Energy Monitoring Code needs PZEM-017 DC Energy Meter to measure values and Arduio Mega / UNO for communication and display.

// Note : This Code monitors DC Voltage, current, Power, and Energy.

// Note : The values shown in LCD Display is refreshed every second.

// Note : The values are calculated internally by energy meter and function of Arduino is only to read the value and for further calculation.

// Note : The first step is need to select shunt value and change the value accordingly. look for line "static uint16_t NewshuntAddr = 0x0000; "

// Note : You need to download and install (modified) Modbus Master library at our website (PZEM-014 or 016 AC Energy Meter with Arduino – A blog about DIY solar and arduino projects )

// Note : The Core of the code was from EvertDekker.com 2018 which based on the example from PZEM-016 with Arduino PZEM-014 RS485 Modbus - Solar4Living

// Note : Solarduino only amend necessary code and integrate with LCD Display Shield.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////*/

/* 1- PZEM-017 DC Energy Meter */

#include <ModbusMaster.h> // Load the (modified) library for modbus communication command codes. Kindly install at our website.

#define MAX485_DE 2 // Define DE Pin to Arduino pin. Connect DE Pin of Max485 converter module to Pin 2 (default) Arduino board

#define MAX485_RE 3// Define RE Pin to Arduino pin. Connect RE Pin of Max485 converter module to Pin 3 (default) Arduino board

// These DE anr RE pins can be any other Digital Pins to be activated during transmission and reception process.

static uint8_t pzemSlaveAddr = 0x01; // Declare the address of device (meter) in term of 8 bits. You can change to 0x02 etc if you have more than 1 meter.

static uint16_t NewshuntAddr = 0x0000; // Declare your external shunt value. Default is 100A, replace to "0x0001" if using 50A shunt, 0x0002 is for 200A, 0x0003 is for 300A

// By default manufacturer may already set, however, to set manually kindly delete the "//" for line "// setShunt(0x01);" in void setup

ModbusMaster node; /* activate modbus master codes*/

float PZEMVoltage =0; /* Declare value for DC voltage */

float PZEMCurrent =0; /* Declare value for DC current*/

float PZEMPower =0; /* Declare value for DC Power */

float PZEMEnergy=0; /* Declare value for DC Energy */

unsigned long startMillisPZEM; /* start counting time for LCD Display */

unsigned long currentMillisPZEM; /* current counting time for LCD Display */

const unsigned long periodPZEM = 1000; // refresh every X seconds (in seconds) in LED Display. Default 1000 = 1 second

int page = 1; /* display different pages on LCD Display*/

/* 2 - LCD Display */

#include<LiquidCrystal.h> /* Load the liquid Crystal Library (by default already built-it with arduino solftware)*/

LiquidCrystal LCD(48,49,4,5,6,7); /* Creating the LiquidCrystal object named LCD. The pin may be varies based on LCD module that you use*/

unsigned long startMillisLCD; /* start counting time for LCD Display */

unsigned long currentMillisLCD; /* current counting time for LCD Display */

const unsigned long periodLCD = 1000; /* refresh every X seconds (in seconds) in LED Display. Default 1000 = 1 second */

int ResetEnergy = 0; /* reset energy function */

unsigned long startMillisEnergy; /* start counting time for LCD Display */

unsigned long currentMillisEnergy; /* current counting time for LCD Display */

const unsigned long periodEnergy = 1000; // refresh every X seconds (in seconds) in LED Display. Default 1000 = 1 second

void setup()

{

/0 General/

Serial.begin(9600); /* to display readings in Serial Monitor at 9600 baud rates */

/* 1- PZEM-017 DC Energy Meter */

//setShunt(0x01); // Delete the "//" to set shunt rating (0x01) is the meter address by default

// resetEnergy(0x01); // By delete the double slash symbol, the Energy value in the meter is reset. Can also be reset on the LCD Display

startMillisPZEM = millis(); /* Start counting time for run code */

Serial3.begin(9600,SERIAL_8N2); /* To assign communication port to communicate with meter. with 2 stop bits (refer to manual)*/

// By default communicate via Serial3 port: pin 14 (Tx) and pin 15 (Rx)

node.begin(pzemSlaveAddr, Serial3); /* Define and start the Modbus RTU communication. Communication to specific slave address and which Serial port */

pinMode(MAX485_RE, OUTPUT); /* Define RE Pin as Signal Output for RS485 converter. Output pin means Arduino command the pin signal to go high or low so that signal is received by the converter*/

pinMode(MAX485_DE, OUTPUT); /* Define DE Pin as Signal Output for RS485 converter. Output pin means Arduino command the pin signal to go high or low so that signal is received by the converter*/

digitalWrite(MAX485_RE, 0); /* Arduino create output signal for pin RE as LOW (no output)*/

digitalWrite(MAX485_DE, 0); /* Arduino create output signal for pin DE as LOW (no output)*/

// both pins no output means the converter is in communication signal receiving mode

node.preTransmission(preTransmission); // Callbacks allow us to configure the RS485 transceiver correctly

node.postTransmission(postTransmission);

changeAddress(0xF8,0x01); // By delete the double slash symbol, the meter address will be set as 0x01.

// By default I allow this code to run every program startup. Will not have effect if you only have 1 meter

// changeAddress(0X01, 0XF8);

delay(1000); /* after everything done, wait for 1 second */

/* 2 - LCD Display */

LCD.begin(16,2); /* Tell Arduino that our LCD has 16 columns and 2 rows*/

LCD.setCursor(0,0); /* Set LCD to start with upper left corner of display*/

startMillisLCD = millis(); /* Start counting time for display refresh time*/

}

void loop()

{

/* 0- General */

/* 0.1- Button Function */

int buttonRead;

buttonRead = analogRead (0); // Read analog pin A0. Pin A0 automatically assigned for LCD Display Button function (cannot be changed)

/*Right button is pressed */

if (buttonRead < 60)

{

LCD.setCursor(0,0); LCD.print (" PRESS <SELECT> ");

LCD.setCursor(0,1); LCD.print ("TO RESET ENERGY ");

}

/* Up button is pressed */

else if (buttonRead < 200)

{

LCD.setCursor(0,0); LCD.print (" PRESS <SELECT> ");

LCD.setCursor(0,1); LCD.print ("TO RESET ENERGY ");

}

/* Down button is pressed */

else if (buttonRead < 400)

{

LCD.setCursor(0,0); LCD.print (" PRESS <SELECT> ");

LCD.setCursor(0,1); LCD.print ("TO RESET ENERGY ");

}

/* Left button is pressed */

else if (buttonRead < 600)

{

if(ResetEnergy ==0)

{

LCD.setCursor(0,0); LCD.print (" PRESS <SELECT> ");

LCD.setCursor(0,1); LCD.print ("TO RESET ENERGY ");

}

if(ResetEnergy ==1) /* only to run reset energy if left button is pressed after select button*/

{

page = 2;

}

}

/* Select button is pressed */

else if (buttonRead < 800)

{

ResetEnergy = 1; // to activate offset for power

startMillisEnergy = millis(); /* start counting time for pending response*/

}

/* After Select button is pressed */

if(ResetEnergy ==1)

{

LCD.setCursor(0,0); /* set display words starting at upper left corner*/

LCD.print ("RESET ENERGY ? ");

LCD.setCursor(0,1); /* set display words starting at lower left corner*/

LCD.print ("PRESS < LEFT > ");

currentMillisEnergy = millis();

if(( currentMillisEnergy - startMillisEnergy <= 5000) && (page==2)) /* if within 5 seconds <left> button is pressed, do reset energy*/

{

// Reset energy

uint16_t u16CRC = 0xFFFF; /* declare CRC check 16 bits*/

static uint8_t resetCommand = 0x42; /* reset command code*/

uint8_t slaveAddr =0X01;

u16CRC = crc16_update(u16CRC, slaveAddr);

u16CRC = crc16_update(u16CRC, resetCommand);

Serial.println("Resetting Energy");

preTransmission(); /* trigger transmission mode*/

Serial3.write(slaveAddr); /* send device address in 8 bit*/

Serial3.write(resetCommand); /* send reset command */

Serial3.write(lowByte(u16CRC)); /* send CRC check code low byte (1st part) */

Serial3.write(highByte(u16CRC)); /* send CRC check code high byte (2nd part) */

delay(10);

postTransmission(); /* trigger reception mode*/

delay(100);

while (Serial3.available()) /* while receiving signal from Serial3 from meter and converter */

{

Serial.print(char(Serial3.read()), HEX); /* Prints the response and display on Serial Monitor (Serial)*/

Serial.print(" ");

}

ResetEnergy=0; /* reset command switch back to default*/

page=1; /* go back to page 1 after reset*/

}

if(( currentMillisEnergy - startMillisEnergy > 5000) && (page!=2)) /* if more than 5 seconds <Left> button does not pressed, go back to main page*/

{

ResetEnergy=0; /* reset command switch back to default*/

page=1; /* go back to page 1 after reset*/

}

}

/* 1- PZEM-017 DC Energy Meter */

currentMillisPZEM = millis(); /* count time for program run every second (by default)*/

if (currentMillisPZEM - startMillisPZEM >= periodPZEM) /* for every x seconds, run the codes below*/

{

uint8_t result; /* Declare variable "result" as 8 bits */

result = node.readInputRegisters(0x0000, 6); /* read the 9 registers (information) of the PZEM-014 / 016 starting 0x0000 (voltage information) kindly refer to manual)*/

if (result == node.ku8MBSuccess) /* If there is a response */

{

uint32_t tempdouble = 0x00000000; /* Declare variable "tempdouble" as 32 bits with initial value is 0 */

PZEMVoltage = node.getResponseBuffer(0x0000) / 100.0; /* get the 16bit value for the voltage value, divide it by 100 (as per manual) */

// 0x0000 to 0x0008 are the register address of the measurement value

PZEMCurrent = node.getResponseBuffer(0x0001) / 100.0; /* get the 16bit value for the current value, divide it by 100 (as per manual) */

tempdouble = (node.getResponseBuffer(0x0003) << 16) + node.getResponseBuffer(0x0002); /* get the power value. Power value is consists of 2 parts (2 digits of 16 bits in front and 2 digits of 16 bits at the back) and combine them to an unsigned 32bit */

PZEMPower = tempdouble / 10.0; /* Divide the value by 10 to get actual power value (as per manual) */

tempdouble = (node.getResponseBuffer(0x0005) << 16) + node.getResponseBuffer(0x0004); /* get the energy value. Energy value is consists of 2 parts (2 digits of 16 bits in front and 2 digits of 16 bits at the back) and combine them to an unsigned 32bit */

PZEMEnergy = tempdouble;

Serial.print(PZEMVoltage, 1); /* Print Voltage value on Serial Monitor with 1 decimal*/

Serial.print("V ");

Serial.print(PZEMCurrent, 3);

Serial.print("A ");

Serial.print(PZEMPower, 1);

Serial.print("W ");

Serial.print(PZEMEnergy, 0);

Serial.print("Wh ");

Serial.println();

if (pzemSlaveAddr==2) /* just for checking purpose to see whether can read modbus*/

{

Serial.println();

}

}

else

{

Serial.println("Failed to read modbus");

}

startMillisPZEM = currentMillisPZEM ; /* Set the starting point again for next counting time */

}

/* 2 - LCD Display */

currentMillisLCD = millis(); /* Set counting time for LCD Display*/

if (currentMillisLCD - startMillisLCD >= periodLCD) /* for every x seconds, run the codes below*/

{

if( page ==1)

{

LCD.setCursor(0,0); /* Set cursor to first colum 0 and second row 1 */

LCD.print(PZEMVoltage, 1); /* Display Voltage on LCD Display with 1 decimal*/

LCD.print("V ");

LCD.setCursor(9,0);

LCD.print(PZEMEnergy, 0);

LCD.print("Wh ");

LCD.setCursor(0,1);

LCD.print(PZEMCurrent, 2);

LCD.print("A ");

LCD.setCursor(9,1);

LCD.print(PZEMPower, 1);

LCD.print("W ");

startMillisLCD = currentMillisLCD ; /* Set the starting point again for next counting time */

}

}

}

void preTransmission() /* transmission program when triggered*/

{

/* 1- PZEM-017 DC Energy Meter */

digitalWrite(MAX485_RE, 1); /* put RE Pin to high*/

digitalWrite(MAX485_DE, 1); /* put DE Pin to high*/

delay(1); // When both RE and DE Pin are high, converter is allow to transmit communication

}

void postTransmission() /* Reception program when triggered*/

{

/* 1- PZEM-017 DC Energy Meter */

delay(3); // When both RE and DE Pin are low, converter is allow to receive communication

digitalWrite(MAX485_RE, 0); /* put RE Pin to low*/

digitalWrite(MAX485_DE, 0); /* put DE Pin to low*/

}

void setShunt(uint8_t slaveAddr) //Change the slave address of a node

{

/* 1- PZEM-017 DC Energy Meter */

static uint8_t SlaveParameter = 0x06; /* Write command code to PZEM */

static uint16_t registerAddress = 0x0003; /* change shunt register address command code */

uint16_t u16CRC = 0xFFFF; /* declare CRC check 16 bits*/

u16CRC = crc16_update(u16CRC, slaveAddr); // Calculate the crc16 over the 6bytes to be send

u16CRC = crc16_update(u16CRC, SlaveParameter);

u16CRC = crc16_update(u16CRC, highByte(registerAddress));

u16CRC = crc16_update(u16CRC, lowByte(registerAddress));

u16CRC = crc16_update(u16CRC, highByte(NewshuntAddr));

u16CRC = crc16_update(u16CRC, lowByte(NewshuntAddr));

Serial.println("Change shunt address");

preTransmission(); /* trigger transmission mode*/

Serial3.write(slaveAddr); /* these whole process code sequence refer to manual*/

Serial3.write(SlaveParameter);

Serial3.write(highByte(registerAddress));

Serial3.write(lowByte(registerAddress));

Serial3.write(highByte(NewshuntAddr));

Serial3.write(lowByte(NewshuntAddr));

Serial3.write(lowByte(u16CRC));

Serial3.write(highByte(u16CRC));

delay(10);

postTransmission(); /* trigger reception mode*/

delay(100);

while (Serial3.available()) /* while receiving signal from Serial3 from meter and converter */

{

Serial.print(char(Serial3.read()), HEX); /* Prints the response and display on Serial Monitor (Serial)*/

Serial.print(" ");

}

}

void changeAddress(uint8_t OldslaveAddr, uint8_t NewslaveAddr) //Change the slave address of a node

{

/* 1- PZEM-017 DC Energy Meter */

static uint8_t SlaveParameter = 0x06; /* Write command code to PZEM */

static uint16_t registerAddress = 0x0002; /* Modbus RTU device address command code */

uint16_t u16CRC = 0xFFFF; /* declare CRC check 16 bits*/

u16CRC = crc16_update(u16CRC, OldslaveAddr); // Calculate the crc16 over the 6bytes to be send

u16CRC = crc16_update(u16CRC, SlaveParameter);

u16CRC = crc16_update(u16CRC, highByte(registerAddress));

u16CRC = crc16_update(u16CRC, lowByte(registerAddress));

u16CRC = crc16_update(u16CRC, highByte(NewslaveAddr));

u16CRC = crc16_update(u16CRC, lowByte(NewslaveAddr));

Serial.println("Change Slave Address");

preTransmission(); /* trigger transmission mode*/

Serial3.write(OldslaveAddr); /* these whole process code sequence refer to manual*/

Serial3.write(SlaveParameter);

Serial3.write(highByte(registerAddress));

Serial3.write(lowByte(registerAddress));

Serial3.write(highByte(NewslaveAddr));

Serial3.write(lowByte(NewslaveAddr));

Serial3.write(lowByte(u16CRC));

Serial3.write(highByte(u16CRC));

delay(10);

postTransmission(); /* trigger reception mode*/

delay(100);

while (Serial3.available()) /* while receiving signal from Serial3 from meter and converter */

{

Serial.print(char(Serial3.read()), HEX); /* Prints the response and display on Serial Monitor (Serial)*/

Serial.print(" ");

}

}

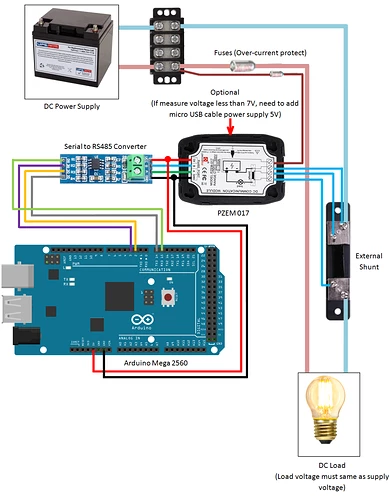

I used above code but that is not work. And I connect between Rs485,DC commucation module and Arduino Mega as below photo.This code is shown "Change slave address and failed to read modulus" in Serial monitor.