Dear ALL, I'm very new on arduino ![]() ,

,

I need help to solve at my project.

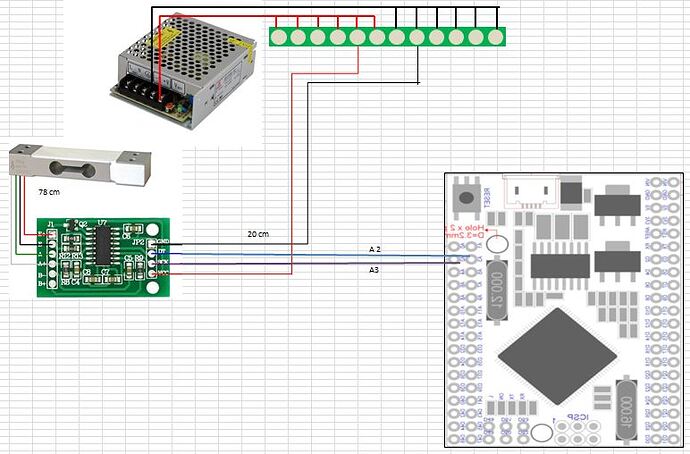

Description on my project

I use load cell, motor stepper (to move chain), motor servo (to reject product), LCD, Keypad

and the Function

If I push button "A" Motor running

If I push button "B" load cell Weighing after 2 second arduino will decided good/bad product and send order to servo to move from position 0 to 90.(problem motor servo can't hold position at least 2 second) another problem how to make motor stepper move after 2 second arduino decide good/bad product)

Problem:

- How to show up the text on LCD while i turn on the motor(Fyi, i already try to combine on void motor i input "program LCD" but the result is LCD blank and motor run very slow?

- How to make servo at pos 90'(bad) little bit hold the position while we push the product?

- How to make stepper move while arduino decide product good/bad?

Thanks

Best Regards

Doni

this is the program:(i combine all programs as possible)

#include <LiquidCrystal_I2C.h>

#include <Wire.h>

#include <Keypad.h>

#include <HX711_ADC.h>

#include <EEPROM.h>

#include <Servo.h>

//Servo

Servo servo;

int pos = 0;

// Keypad

const byte ROWS = 4;

const byte COLS = 4;

char hexaKeys[ROWS][COLS] = {

{'1', '2', '3', 'A'},

{'4', '5', '6', 'B'},

{'7', '8', '9', 'C'},

{'*', '0', '#', 'D'}

};

byte rowPins[ROWS] = {46, 44, 42, 40};

byte colPins[COLS] = {38, 36, 34, 32};

Keypad customKeypad = Keypad( makeKeymap(hexaKeys), rowPins, colPins, ROWS, COLS);

// LCD

LiquidCrystal_I2C lcd(0x27, 20, 4);

//HX711

const int HX711_dout = 6; //mcu > HX711 dout pin

const int HX711_sck = 7; //mcu > HX711 sck pin

const int calVal_calVal_eepromAdress = 0;

long t;

HX711_ADC LoadCell(HX711_dout, HX711_sck);

//Sensor PX dan IR

int ir = 31;

int px = 30;

unsigned long preMil = 0;

unsigned long previousMicros = 0;

const long interval = 1500;

int PULPin = 3; // PUL- pin

int DIRPin = 2; // DIR- pin

int PULState = HIGH;

int B = 0;

float j;

float i;

void setup() {

// servo

servo.attach(9);

// Setup HX711

Serial.begin(9600); delay(10);

Serial.println();

Serial.println("Starting...");

float calibrationValue; // calibration value

calibrationValue = 696.0; // uncomment this if you want to set this value in the sketch

#if defined(ESP8266) || defined(ESP32)

#endif

value from eeprom

LoadCell.begin();

long stabilizingtime = 2000; // tare preciscion can be improved by adding a few seconds of stabilizing time

boolean _tare = true; //set this to false if you don't want tare to be performed in the next step

LoadCell.start(stabilizingtime, _tare);

if (LoadCell.getTareTimeoutFlag()) {

Serial.println("Timeout, check MCU>HX711 wiring and pin designations");

}

else {

LoadCell.setCalFactor(calibrationValue); // set calibration factor (float)

Serial.println("Startup is complete");

}

while (!LoadCell.update());

Serial.print("Calibration value: ");

Serial.println(LoadCell.getCalFactor());

Serial.print("HX711 measured conversion time ms: ");

Serial.println(LoadCell.getConversionTime());

Serial.print("HX711 measured sampling rate HZ: ");

Serial.println(LoadCell.getSPS());

Serial.print("HX711 measured settlingtime ms: ");

Serial.println(LoadCell.getSettlingTime());

Serial.println("Note that the settling time may increase significantly if you use delay() in your sketch!");

if (LoadCell.getSPS() < 7) {

Serial.println("!!Sampling rate is lower than specification, check MCU>HX711 wiring and pin designations");

}

else if (LoadCell.getSPS() > 100) {

Serial.println("!!Sampling rate is higher than specification, check MCU>HX711 wiring and pin designations");

}

//Setup LCD

lcd.clear();

lcd.begin();

lcd.backlight();

//Setup Stepper

pinMode (PULPin, OUTPUT);

pinMode (DIRPin, OUTPUT);

//Setup Sensor PX dan IR

pinMode(px, INPUT);

pinMode(ir, INPUT);

}

void MSON()//Motor Stepper ON

{

digitalWrite(DIRPin, LOW);

unsigned long currentMicros = micros();

if (currentMicros - previousMicros >= interval)

{

previousMicros = currentMicros;

if (PULState == HIGH)

{

PULState = LOW;

}

else {

PULState = HIGH;

}

digitalWrite(PULPin, PULState);

}

// unsigned long curMil = millis();

// if (curMil - preMil >= 100)

// {preMil = curMil;

// }

}

void weighing()

{

lcd.print("weight : ");

lcd.setCursor(15, 2);

lcd.print("gram");

static boolean newDataReady = 0;

const int serialPrintInterval = 500; //increase value to slow down serial print activity

// check for new data/start next conversion:

if (LoadCell.update()) newDataReady = true;

// get smoothed value from the dataset:

if (newDataReady)

{

if (millis() > t + serialPrintInterval)

{

float i = LoadCell.getData();

Serial.print("Load_cell output val: ");

Serial.println(i);

float j = i / 10;

lcd.setCursor(8, 2);

lcd.print(j);

if (j >= 60 && j <= 71.0)

{

lcd.setCursor(0, 3);

lcd.print("Good");

}

if (j < 60 || j > 71.0)

{

lcd.setCursor(0, 3);

lcd.print("Bad");

}

newDataReady = 0;

t = millis();

}

}

// receive command from serial terminal, send 't' to initiate tare operation:

if (Serial.available() > 0)

{

float i;

char inByte = Serial.read();

if (inByte == 't') LoadCell.tareNoDelay();

}

// check if last tare operation is complete:

if (LoadCell.getTareStatus() == true)

{

Serial.println("Tare complete");

}

}

void loop()

{

if (B == 0)

{

lcd.setCursor(0, 0);

lcd.print("Tekan tombol untuk");

lcd.setCursor(1, 1);

lcd.print("A : START MOTOR");

lcd.setCursor(2, 2);

lcd.print("B : START Weighing");

}

char customKey = customKeypad.getKey();

switch (customKey)

if (B == 3)

{

lcd.setCursor(0, 0);

lcd.print("Press button for");

lcd.setCursor(1, 1);

lcd.print("A : START MOTOR");

lcd.setCursor(2, 2);

lcd.print("B : START Weighing");

}

if (B == 1)

{ MSON();

}

if (B == 2)

{

for (int x = 0; x < 201 ; x++)

{ weighing();

Serial.println("Progress Weighing");

}

for (int x = 200; x >= 1 ; x--)

{

Serial.println("Servo");

if (j >= 60 && j <= 71.0)

{

Serial.println("good");

servo.write(0);

}

else

{ Serial.println("bad");

servo.write(90);

}

lcd.clear();

B = 1;

}

}

}