That was actually in reply to zoomkats response on the previous page (i didnt refresh and had actually missed this entire page of discussion)! I am not ignoring anyones posts, but rather still haven't come to a conclusion about the optimal approach yet.

There are actually three different designs that that people have proposed that i find super compelling:

There's Drazzy's suggestion of making every pixel independant using attiny85's to control each one, which i dig since its super robust

Theres Paul__B's suggestion of using multiple cheap boards for groups of encoders, which i like since it's the most straight forward to implement (for the most part its things i've done before)

And there is Zoomkat's suggestion of using a single board, and a bunch of muxers, which is by far the cheapest approach though it's not clear to me how to swap in the encoders to use the muxers.

I keep going around in my head which one i want to pursue! I think i like the independent pixel idea, if i can make them cheaper. So while i was putting that decision off i took a moment to mock out a design for the actual led modules i intended to build, and discovered a problem that might make me abandon the encoder (or at least prevent continuous rotation):

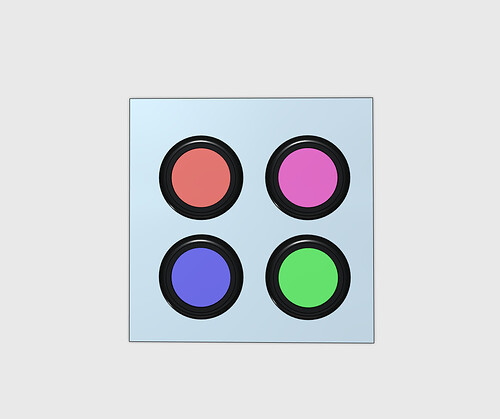

Here is a face-on view that a user would see. As you rotate the black part, the bit in the center changes color. Should be pretty straight forward:

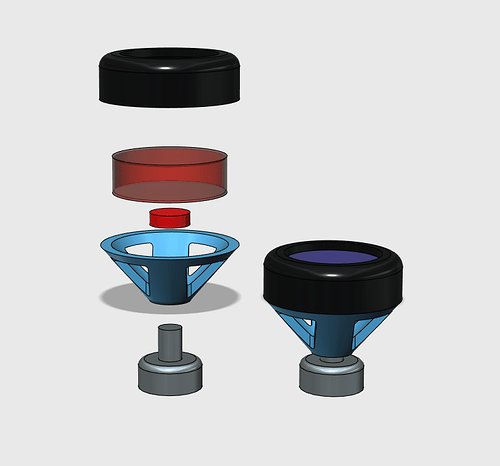

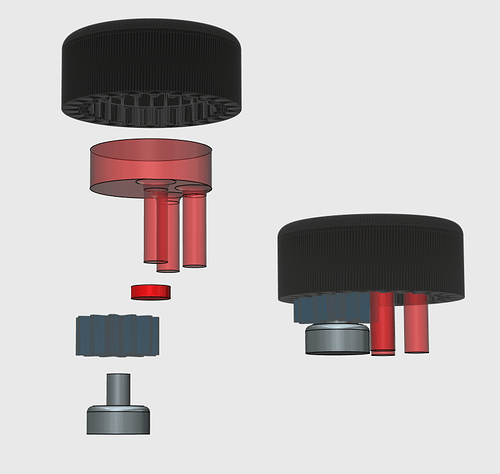

and here is a side view of the components of the LED modules:

From top to bottom, the components are:

-Outer hub (the part you grab and turn)

-LED Diffuser (make a nice consistent light)

-LED/Neo Pixel

-Inner hub (grabs and turns the sensor)

-Sensor

So you can see from this, the LED is in the middle of hte module, so the wires to control it go up through those holes. As the module is rotated, it will begin tangle up the wires, and if there is no endstop it will eventually rip them out.

The only other approach would I can think of would be to move the sensor to the side and have a belt or gear drive the rotation of the sensor, but i am not sure the complexity is worth it.