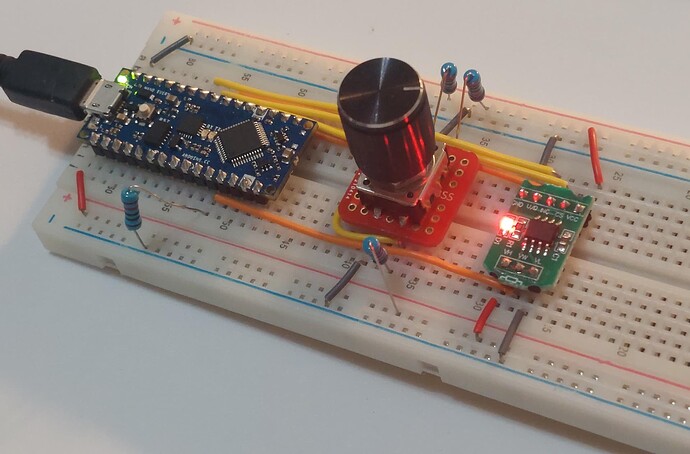

First off... I must apologize for this shotty looking diagram, but hopefully it helps:

I plan on using a digital potentiometer in a project I'm working on and this is an example circuit. It basically uses a rotary encoder to control the X9C103P digipot, and a voltage divider with a 10kohm resistor to check the voltage and calculate the resistance.

Here's the code:

#include <X9C.h> // X9C pot library

#define UD 7 // pot up/down mode pin

#define INC 6 // pot increment pin

#define CS 5 // pot chip select pin

#define POT_READING 7 // Analog pin for potentiometer

// Seems odd to have 2 pins set to "7", but

// POT_READING will be reading from A7 and

// UD will be writing to D7

// Rotary Encoder Inputs

#define ENCODER_DT 2 // Encoder output A (... or is it B?... idk)

#define ENCODER_CLK 3 // Encoder output B?

#define ENCODER_SW 4 // Encoder switch/button, will set the digipot to encoders val

#define ENCODER_MIN 0 // Minimum encoder value

#define ENCODER_MAX 99 // Max value from encoder (the X9C library allows max 99 )

int encoderPos = 0; // Position of encoder, restricted to the ENCODER_[MAX/MIN] vals

int currentStateCLK; // Input from encoders CLK pin

int lastStateCLK; // Value of the CLK in the last loop (checking for updates)

bool clkClockwise; // True if rotary is turning clockwise (this isn't really used).

int loopCounter = 0; // Keep track of loop iteration count

int printOhmsEvery = 100;// How often to print the output (avoiding delay())

int ohmReading; // Output of the X9C103P

int lastOhmReading; // Value of the X9C103P in the last iteration

int buttonState; // the current reading from the input pin

int lastButtonState = LOW;// the previous reading from the input pin

unsigned long lastDebounceTime = 0; // the last time the output pin was toggled

unsigned long debounceDelay = 50; // the debounce time; increase if the output flickers

// Vals for the volts to ohms conversion via Ohms law

int raw = 0;

float Vin = 5;

float Vout = 0;

// Known resistor value

float R1 = 10060;

float R2 = 0;

float buffer = 0;

float R2_previous = 0;

X9C pot;

void setup() {

// Set encoder pins as inputs

pinMode(ENCODER_CLK,INPUT);

pinMode(ENCODER_DT,INPUT);

pinMode(ENCODER_SW, INPUT);

// Setup Serial Monitor

Serial.begin(9600);

// Read the initial state of CLK

lastStateCLK = digitalRead(ENCODER_CLK);

//lastStateSW = digitalRead(SW);

// Call updateEncoder() when any high/low changed seen

// on interrupt 0 (pin 2), or interrupt 1 (pin 3)

attachInterrupt(ENCODER_CLK, updateEncoder, CHANGE);

attachInterrupt(ENCODER_DT, updateEncoder, CHANGE);

pot.begin(CS, INC, UD);

}

void setPot( int targetPos ){

pot.setPot(targetPos);

}

void loop() {

loopCounter++;

int reading = digitalRead(ENCODER_SW);

// If the switch changed, due to noise or pressing:

if (reading != lastButtonState) {

// reset the debouncing timer

lastDebounceTime = millis();

}

if ((millis() - lastDebounceTime) > debounceDelay) {

// whatever the reading is at, it's been there for longer than the debounce

// delay, so take it as the actual current state:

// if the button state has changed:

if (reading != buttonState) {

buttonState = reading;

// only toggle the LED if the new button state is HIGH

if (buttonState == LOW) {

//Serial.println("Button has been pressed..");

setPot(encoderPos);

}

}

}

// set the LED:

// save the reading. Next time through the loop, it'll be the lastButtonState:

lastButtonState = reading;

ohmReading = analogRead(POT_READING);

lastOhmReading = ohmReading;

if ( loopCounter > printOhmsEvery && loopCounter % printOhmsEvery == 0 ){

buffer = ohmReading * Vin;

Vout = (buffer)/1023.0;

buffer = (Vin/Vout) - 1;

R2= R1 * buffer;

Serial.print("Vout:");

Serial.print(Vout);

Serial.print(",R2:");

Serial.print(R2);

Serial.print(",encoderPos:");

Serial.println(encoderPos);

R2_previous = R2;

}

}

void updateEncoder(){

// Read the current state of CLK

currentStateCLK = digitalRead(ENCODER_CLK);

// If last and current state of CLK are different, then pulse occurred

// React to only 1 state change to avoid double count

if (currentStateCLK != lastStateCLK && currentStateCLK == 1){

// If the DT state is different than the CLK state then

// the encoder is rotating CCW so decrement

if (digitalRead(ENCODER_DT) != currentStateCLK) {

if ( encoderPos > ENCODER_MIN ) encoderPos --;

clkClockwise = false;// ="CCW";

}

else {

// Encoder is rotating CW so increment

if ( encoderPos < ENCODER_MAX ) encoderPos ++;

clkClockwise = true;

}

}

// Remember last CLK state

lastStateCLK = currentStateCLK;

}

Now the problem I'm having is the value of R2 is way out of range from what I would expect. This is an X9C103, which means it should only be able to provide a resistance up to 10k ohms, but R2 prints out up to 344815.18, which is much higher than I expected.

Vout:0.00,R2:inf,encoderPos:0

Vout:4.69,R2:660.19,encoderPos:4

Vout:4.60,R2:865.03,encoderPos:4

Vout:3.26,R2:5346.26,encoderPos:23

Vout:3.26,R2:5369.36,encoderPos:31

Vout:2.15,R2:13382.78,encoderPos:47

Vout:0.15,R2:332986.03,encoderPos:96

Vout:0.14,R2:344815.18,encoderPos:96

I have a separate circuit where I use the same voltage divider and code to determine the resistance of an "unknown" resistor and it was shockingly accurate. However, when I switch out the unknown resistor with the output from a digital potentiometer, the reading is much higher.

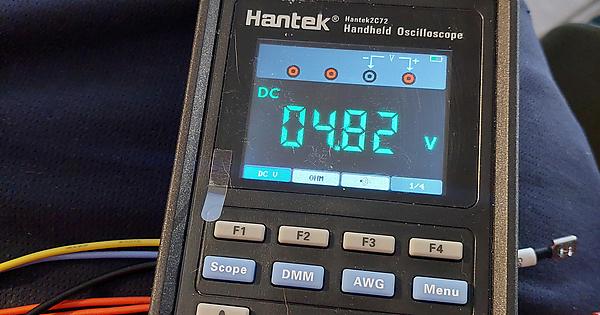

Additionally, the output voltage from the X9C103 (as you can see in the quoted output above), I can actually get it all the way down to almost 0 volts, which is more of a drop in voltage than I expected (and I verified that with my multimeter.

Question time - Why is it that the calculation for R2 reads so much higher through a digipot than if I switch in a regular resistor? I know that these things are only accurate to like 20% or so, but a resistance of over 300% the expected max makes me thing it's just a basic circuit problem or I may need to calculate the resistance here a bit differently.

And just in case anyone needs it, here are some pictures of the actual circuit:

Thank you in advance!

-J