Hi everyone,

I am new to mechatronics and I am building a 2WD car which can be controlled with a XY-axis joystick. Currently everything works.

BOM:

- Ardunio UNO

- L298N H-Bridge

- LCD with I2C module

- Simple XY-Axis joystick

- 2x DC motors geared with Encoder on the shaft (see picture below)

Connections are all good. The car is moving as it should move.

The question here is, how can i display the RPM (Speed) on the display using these encoders on the motors?

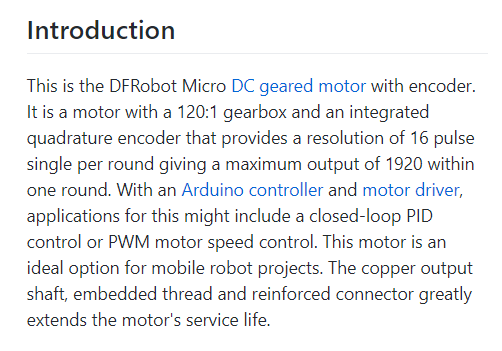

I have connected the pins from the encoder like on the picture below (for both motors on pin 2 and ~3 of the arduino.

CODE

#define enA 9

#define in1 4

#define in2 5

#define enB 10

#define in3 6

#define in4 7

// Library voor de LCD met I2C module (deze module zorgt er voor dat je maar 4 jumperkabels nodig hebt ipv 8)

#include <Wire.h>

#include <LiquidCrystal_I2C.h>

LiquidCrystal_I2C lcd(0x27,16,2);

int motorSpeedA = 0;

int motorSpeedB = 0;

void setup() {

pinMode(enA, OUTPUT);

pinMode(enB, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

// Initialiseren LCD scherm

lcd.init();

lcd.init();

// Display een bericht op de LCD

lcd.backlight();

lcd.setCursor(1,0);

lcd.print("MR.BEAN");

lcd.setCursor(1,1);

lcd.print("ROBOT AUTO");

}

void loop() {

int xAxis = analogRead(A0); // Read Joysticks X-axis

int yAxis = analogRead(A1); // Read Joysticks Y-axis

// Y-axis used for forward and backward control

if (yAxis < 470) {

// Set Motor A backward

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

// Set Motor B backward

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

// Convert the declining Y-axis readings for going backward from 470 to 0 into 0 to 255 value for the PWM signal for increasing the motor speed

motorSpeedA = map(yAxis, 470, 0, 0, 255);

motorSpeedB = map(yAxis, 470, 0, 0, 255);

}

else if (yAxis > 550) {

// Set Motor A forward

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

// Set Motor B forward

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

// Convert the increasing Y-axis readings for going forward from 550 to 1023 into 0 to 255 value for the PWM signal for increasing the motor speed

motorSpeedA = map(yAxis, 550, 1023, 0, 255);

motorSpeedB = map(yAxis, 550, 1023, 0, 255);

}

// If joystick stays in middle the motors are not moving

else {

motorSpeedA = 0;

motorSpeedB = 0;

}

// X-axis used for left and right control

if (xAxis < 470) {

// Convert the declining X-axis readings from 470 to 0 into increasing 0 to 255 value

int xMapped = map(xAxis, 470, 0, 0, 255);

// Move to left - decrease left motor speed, increase right motor speed

motorSpeedA = motorSpeedA - xMapped;

motorSpeedB = motorSpeedB + xMapped;

// Confine the range from 0 to 255

if (motorSpeedA < 0) {

motorSpeedA = 0;

}

if (motorSpeedB > 255) {

motorSpeedB = 255;

}

}

if (xAxis > 550) {

// Convert the increasing X-axis readings from 550 to 1023 into 0 to 255 value

int xMapped = map(xAxis, 550, 1023, 0, 255);

// Move right - decrease right motor speed, increase left motor speed

motorSpeedA = motorSpeedA + xMapped;

motorSpeedB = motorSpeedB - xMapped;

// Confine the range from 0 to 255

if (motorSpeedA > 255) {

motorSpeedA = 255;

}

if (motorSpeedB < 0) {

motorSpeedB = 0;

}

}

// Prevent buzzing at low speeds (Adjust according to your motors. My motors couldn't start moving if PWM value was below value of 70)

if (motorSpeedA < 70) {

motorSpeedA = 0;

}

if (motorSpeedB < 70) {

motorSpeedB = 0;

}

analogWrite(enA, motorSpeedA); // Send PWM signal to motor A

analogWrite(enB, motorSpeedB); // Send PWM signal to motor B

}