Hello!

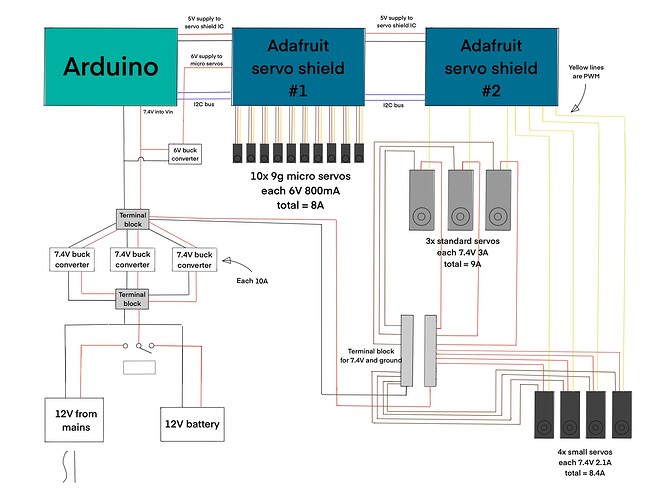

I'm building a robot that contains a variety of different servos. I'm using an Arduino Uno R3 and two Adafruit servo shields (Adafruit 16-channel PWM/Servo Shield). The shields rely on I2C communication and the ICs on them rely on voltage provided by the Arduino, whereas the servos connected to them rely on dedicated power that is also fed into the shields separately.

It occurred to me that with so many high-amperage servos, the shields might not be able to safely handle all that current, so I figured that with the big servos, I would power them separately while leaving their PWM pins connected to the shields.

I've never had to distribute power to a project of this complexity before. I'm quite new to it, so I was wondering if anyone could comment on the setup I've devised:

In my design I am using a total of 20 servos (there would actually be closer to 24 in the final build, but this is a start). I've labelled the operating voltage and maximum current of each servo in the diagram.

I was thinking that I would like to be able to switch between wall power and batter power, so I figured I could place a switch to select between the positive leads of each power source. If this design is flawed, please let me know.

A big issue is making sure that the correct voltages reach each component: 6V for Arduino and micro-servos, 7.4V for larger servos. My research has told me that voltage regulators (perhaps linear or perhaps bucks) would be the way to go here. I would allow the micro servos to be powered through the shield (each shield has a dedicated servo power input, albeit not with that much current allowed), and only connect the PWM leads of the larger servos to the second shield, connecting their positive and ground pins to a dedicated terminal block, which is itself connected to the 7.4V regulator.

Does this all sound sensible? This is my first time doing this, and it's taken me quite a bit of research to figure out how to power so many components. I would also appreciate feedback if anyone has a simpler or more efficient way of accomplishing this configuration of servos. I know for instance that linear voltage regulators can be a bit inefficient. I wrote "12V" for the power sources because it's hard to find power supplies with any less voltage than that but with enough current for all these parts.

Lastly, this design, which looks like it requires about 30 amps of current, is probably a bit overkill. I can all but guarantee that there would never be a point where all 20 servos are running at full power at the same time, but I can't say that it would never get close to that, so I want to be prepared.

Any feedback is appreciated. Thanks!