Hello.

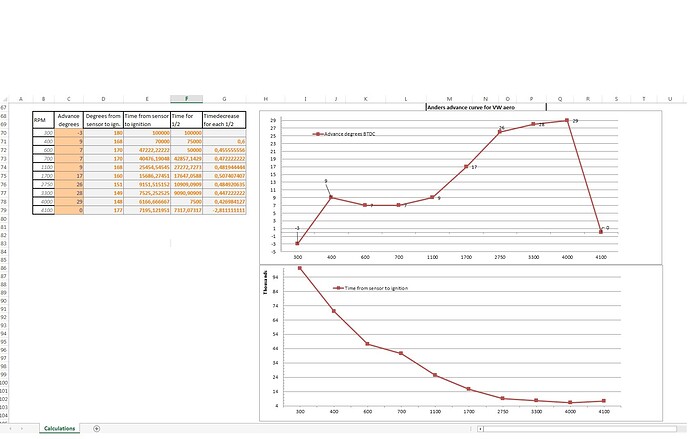

I have not hade the time enought to work on my code a lot, but today I did. I have tried to get rid of the unnecessary calculations and I made an attempt to use crankshaft time instead of rpm. I did make an curve in excell for the cranktime also to get a better understanding. Please have a look at my code and excell sheet.

I have some questions.

First, I have read that calculation with global variables take a lot of memory. I have to use them in my interrupt service routines and interrupts, but in my loop I could move that value to an local variable and use that in my calculations in the loop. Is that a good idea?

The ignition advance time could be coded with about 10 calculation instructions. It could also be coded without calculations, but a lot of if instructions instead (one for every 100rpm for example). What way is the best? What takes most time, and what is most safe/realiable?

Here is one version:

if (halfrev>= 100000 ) { cranktime = 0 ; } // 300

if ((halfrev>= 85714 ) & (halfrev< 100000)){ cranktime = 85476 ;} // 350

if ((halfrev>= 80000 ) & (halfrev< 85714 )){ cranktime = 78667 ;} // 375

if ((halfrev>= 77922 ) & (halfrev< 80000 )){ cranktime = 74025 ;} // 385

if ((halfrev>= 76923 ) & (halfrev< 77922 )){ cranktime = 72222 ;} // 390

if ((halfrev>= 75000 ) & (halfrev< 76923 )){ cranktime = 70000 ;} // 400

if ((halfrev>= 70588 ) & (halfrev< 75000 )){ cranktime = 65921 ;} // 425

if ((halfrev>= 66667 ) & (halfrev< 70588 )){ cranktime = 62333 ;} // 450

if ((halfrev>= 60000 ) & (halfrev< 66667 )){ cranktime = 56267 ;} // 500

if ((halfrev>= 50000 ) & (halfrev< 60000 )){ cranktime = 47222 ;} // 600

if ((halfrev>= 42857 ) & (halfrev< 50000 )){ cranktime = 40476 ;} // 700

if ((halfrev>= 37500 ) & (halfrev< 42857 )){ cranktime = 35417 ;} // 800

if ((halfrev>= 33333 ) & (halfrev< 37500 )){ cranktime = 31481 ;} // 900

if ((halfrev>= 30000 ) & (halfrev< 33333 )){ cranktime = 28333 ;} // 1000

if ((halfrev>= 28571 ) & (halfrev< 30000 )){ cranktime = 26904 ;} // 1050

if ((halfrev>= 27272 ) & (halfrev< 28577 )){ cranktime = 25454 ;} // 1100

if ((halfrev>= 25000 ) & (halfrev< 27272 )){ cranktime = 23152 ;} // 1200

if ((halfrev>= 23076 ) & (halfrev< 25000 )){ cranktime = 21217 ;} // 1300

if ((halfrev>= 21428 ) & (halfrev< 23076 )){ cranktime = 19523 ;} // 1400

if ((halfrev>= 20000 ) & (halfrev< 21428 )){ cranktime = 18056 ;} // 1500

if ((halfrev>= 18750 ) & (halfrev< 20000 )){ cranktime = 16770 ;} // 1600

if ((halfrev>= 17645 ) & (halfrev< 18750 )){ cranktime = 15686 ;} // 1700

if ((halfrev>= 16666 ) & (halfrev< 17647 )){ cranktime = 14759 ;} // 1800

if ((halfrev>= 15789 ) & (halfrev< 16666 )){ cranktime = 13912 ;} // 1900

if ((halfrev>= 15000 ) & (halfrev< 15789 )){ cranktime = 13166 ;} // 2000

if ((halfrev>= 14285 ) & (halfrev< 15000 )){ cranktime = 12460 ;} // 2100

if ((halfrev>= 13636 ) & (halfrev< 14285 )){ cranktime = 11818 ;} // 2200

if ((halfrev>= 13043 ) & (halfrev< 13636 )){ cranktime = 11231 ;} // 2300

if ((halfrev>= 12500 ) & (halfrev< 13043 )){ cranktime = 10715 ;} // 2400

if ((halfrev>= 12000 ) & (halfrev< 12500 )){ cranktime = 10233 ;} // 2500

if ((halfrev>= 11538 ) & (halfrev< 12000 )){ cranktime = 9807 ;} // 2600

if ((halfrev>= 11111 ) & (halfrev< 11538 )){ cranktime = 9382 ;} // 2700

if ((halfrev>= 10909 ) & (halfrev< 11111 )){ cranktime = 9151 ;} // 2750

if ((halfrev>= 10344 ) & (halfrev< 10909 )){ cranktime = 8597 ;} // 2900

if ((halfrev>= 10000 ) & (halfrev< 10344 )){ cranktime = 8288 ;} // 3000

if ((halfrev>= 9677 ) & (halfrev< 10000 )){ cranktime = 8005 ;} // 3100

if ((halfrev>= 9375 ) & (halfrev< 9675 )){ cranktime = 7750 ;} // 3200

if ((halfrev>= 9090 ) & (halfrev< 9375 )){ cranktime = 7510 ;} // 3300

if ((halfrev>= 8823 ) & (halfrev< 9090 )){ cranktime = 7284 ;} // 3400

if ((halfrev>= 8571 ) & (halfrev< 8823 )){ cranktime = 7071 ;} // 3500

if ((halfrev>= 8333 ) & (halfrev< 8571 )){ cranktime = 6870 ;} // 3600

if ((halfrev>= 8108 ) & (halfrev< 8333 )){ cranktime = 6680 ;} // 3700

if ((halfrev>= 7894 ) & (halfrev< 8108 )){ cranktime = 6500 ;} // 3800

if ((halfrev>= 7692 ) & (halfrev< 7894 )){ cranktime = 6329 ;} // 3900

if ((halfrev>= 7500 ) & (halfrev< 7692 )){ cranktime = 6166 ;} // 4000

if ((halfrev>= 7317 ) & (halfrev< 7500 )){ cranktime = 7195 ;} // 4100

And here is an other wersion (the one I use for the moment):

//Following calculations are based on a excell sheet with the advance curve attached.

halfrev= halfrevGlobal; //Transfer global variable value to a lokal for less memory usage ?.

if ((halfrev<= 100000)& (halfrev>= 75000 )){ //Advance from -3 to 9 @ 300-399 rpm

cranktime=(halfrev+600/1000)-dwellTime;}

if ((halfrev<= 75000 ) & (halfrev> 50000 )){ ///Advance from 9 to 7 @ 400-599 rpm

cranktime=(halfrev+456/1000)-dwellTime;}

if ((halfrev<= 50000 ) & (halfrev> 42857 )){ ///Advance from 7 to 7 @ 600-699 rpm

cranktime=(halfrev+472/1000)-dwellTime;}

if ((halfrev<= 42857 ) & (halfrev> 27273 )){ ///Advance from 7 to 9 @ 700-1199 rpm

cranktime=(halfrev+482/1000)-dwellTime;}

if ((halfrev<= 27273 ) & (halfrev> 17647 )){ ///Advance from 9 to 17 @ 1100-1699 rpm

cranktime=(halfrev+507/1000)-dwellTime;}

if ((halfrev<= 17647 ) & (halfrev> 10909 )){ ///Advance from 17 to 26 @ 1700-2749 rpm

cranktime=(halfrev+485/1000)-dwellTime;}

if ((halfrev<= 10909 ) & (halfrev> 9091 )){ ///Advance from 26 to 28 @ 2750-3299 rpm

cranktime=(halfrev+447/1000)-dwellTime;}

if ((halfrev<= 9091 ) & (halfrev> 7500 )){ ///Advance from 28 to 29 @ 3300-3999 rpm

cranktime=(halfrev+427/1000)-dwellTime;}

if ((halfrev<= 7500 ) & (halfrev> 7317 )){ ///Advance from 29 to 0 @ 4000-4100 rpm (rev limitation)

cranktime=(halfrev-281/1000)-dwellTime;}

Wich way is the best for my application?

I have attached the new code and

Do be careful not to take the input voltages below ground. Over time

this can stress the input protection circuitry, causing premature failure.

IDo you have any advice how to address this? Using a 330ohm resistor maybe?

One last thing, I believe the dwell time is suppose to be the time that

the coil is being charged before the flyback.

Yes, that I know and I have that in my calculations and code.

Also make sure you driving transistors are rated for at lest 1Kv when

they turn off.

I am using an Bosch VAG coilpack whit built in transistor logic (igniter). I hope that will turn out fine because MegaJolt uses them also.

Have a nice day!

Arduino_EIS_160131.ino (8.12 KB)