hello and thank you for taking the time to read this.

i am working on a project for something i have always wanted to do.

the overall goal of the project is to have a stand alone display which read information of the CAN bus in my car, and display it on an OLED or LCD.

so far i have started with some sketches that already exist for CAN and OBD. i have started with an OBD PID Request sketch.

what the sketch does: sends a "request" message to the car's ECM. then using the serial monitor the sketch displays all the CAN data received.

so far so good.

i want to send requests for multiple parameters to the ECM. Which i have accomplished.

i also want to display this information onto an OLED or LCD. I am comfortable using the displays.

here is the missing link:

after i send a PID request, i want to filter the CAN messages received, look for a specific message, and save only that message to somewhere in the RAM.

this program so far, will read all the CAN data on the bus. which is great but i am at a loss on how to filter out what i want in software.

Example:

send message 7DF 02 01 05 55 55 55 55 55 (this is the message to request coolant temp from the ECM)

i want to filter the incoming messages to be left with only the one message

what i am trying to filter for: 7E8 03 41 05 40 XX XX XX XX

i would like to be able to take byte 3 (the 40) and store it somewhere in ram

then, do the same thing for the next message that i send, and so on.

i have tried a couple of things, but have had no luck.

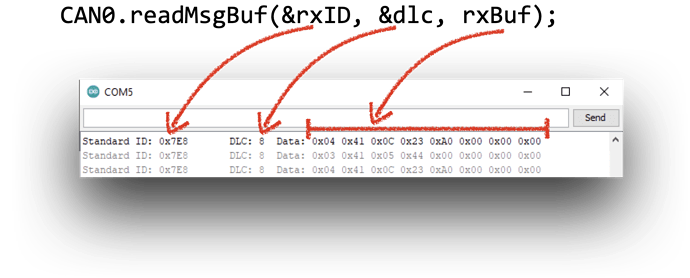

i have attached what some of the data looks like on the serial monitor in the picture

please let me know if there is any other information that i can provide to help in my quest for knowledge.

here is my code

i am not going to take credit for writing all of this. It came from one of the CAN libraries. I have made some small modifications to it.

#include <mcp_can.h>

#include <SPI.h>

#define standard 1 ///changed standard from 0 to 1

// 7E0/8 = Engine ECM

// 7E1/9 = Transmission ECM

#if standard == 1

#define LISTEN_ID 0x7EA

#define REPLY_ID 0x7E0

#define FUNCTIONAL_ID 0x7DF

#define FUNCTIONAL_ID_1 0x7DE //i added this one

#else

#define LISTEN_ID 0x98DAF101

#define REPLY_ID 0x98DA01F1

#define FUNCTIONAL_ID 0x98DB33F1

#endif

// CAN TX Variables

unsigned long prevTx = 0;

unsigned int invlTx = 1000;

byte txData[] = {0x02,0x01,0x00,0x55,0x55,0x55,0x55,0x55};

byte txData1[] = {0x02,0x01,0x05,0x55,0x55,0x55,0x55,0x55};//i added this

// CAN RX Variables

unsigned long rxID;

byte dlc;

byte rxBuf[8];

char msgString[128]; // Array to store serial string

// CAN Interrupt and Chip Select Pins

#define CAN0_INT 2 /* Set INT to pin 2 (This rarely changes) */

MCP_CAN CAN0(9); /* Set CS to pin 9 (Old shields use pin 10) */

void setup(){

Serial.begin(115200);

while(!Serial);

// Initialize MCP2515 running at 16MHz with a baudrate of 500kb/s and the masks and filters disabled.

if(CAN0.begin(MCP_STDEXT, CAN_500KBPS, MCP_16MHZ) == CAN_OK)

Serial.println("MCP2515 Initialized Successfully!");

else{

Serial.println("Error Initializing MCP2515... Permanent failure! Check your code & connections");

while(1);

}

//

// // Allow all Standard IDs

// CAN0.init_Mask(0,0x00000000); // Init first mask...

// CAN0.init_Filt(0,0x00000000); // Init first filter...

// CAN0.init_Filt(1,0x00000000); // Init second filter...

// // Allow all Extended IDs

// CAN0.init_Mask(1,0x80000000); // Init second mask...

// CAN0.init_Filt(2,0x80000000); // Init third filter...

// CAN0.init_Filt(3,0x80000000); // Init fouth filter...

// CAN0.init_Filt(4,0x80000000); // Init fifth filter...

// CAN0.init_Filt(5,0x80000000); // Init sixth filter...

#if standard == 1

// Standard ID Filters

CAN0.init_Mask(0,0x7F00000); // Init first mask...

CAN0.init_Filt(0,0x7DF0000); // Init first filter...

CAN0.init_Filt(1,0x7E10000); // Init second filter...

CAN0.init_Mask(1,0x7F00000); // Init second mask...

CAN0.init_Filt(2,0x7DF0000); // Init third filter...

CAN0.init_Filt(3,0x7E10000); // Init fouth filter...

CAN0.init_Filt(4,0x7DF0000); // Init fifth filter...

CAN0.init_Filt(5,0x7E10000); // Init sixth filter...

#else

// Extended ID Filters

CAN0.init_Mask(0,0x90FF0000); // Init first mask...

CAN0.init_Filt(0,0x90DA0000); // Init first filter...

CAN0.init_Filt(1,0x90DB0000); // Init second filter...

CAN0.init_Mask(1,0x90FF0000); // Init second mask...

CAN0.init_Filt(2,0x90DA0000); // Init third filter...

CAN0.init_Filt(3,0x90DB0000); // Init fouth filter...

CAN0.init_Filt(4,0x90DA0000); // Init fifth filter...

CAN0.init_Filt(5,0x90DB0000); // Init sixth filter...

#endif

CAN0.setMode(MCP_NORMAL); // Set operation mode to normal so the MCP2515 sends acks to received data.

// Having problems? ======================================================

// If you are not receiving any messages, uncomment the setMode line below

// to test the wiring between the Ardunio and the protocol controller.

// The message that this sketch sends should be instantly received.

// ========================================================================

//CAN0.setMode(MCP_LOOPBACK);

pinMode(CAN0_INT, INPUT); // Configuring pin for /INT input

Serial.println("Simple CAN OBD-II PID Request");

}

void loop(){

if(!digitalRead(CAN0_INT)){ // If CAN0_INT pin is low, read receive buffer

CAN0.readMsgBuf(&rxID, &dlc, rxBuf); // Get CAN data

// Display received CAN data as we receive it.

if((rxID & 0x80000000) == 0x80000000) // Determine if ID is standard (11 bits) or extended (29 bits)

sprintf(msgString, "Extended ID: 0x%.8lX DLC: %1d Data:", (rxID & 0x1FFFFFFF), dlc);

else

sprintf(msgString, "Standard ID: 0x%.3lX DLC: %1d Data:", rxID, dlc);

Serial.print(msgString);

if((rxID & 0x40000000) == 0x40000000){ // Determine if message is a remote request frame.

sprintf(msgString, " REMOTE REQUEST FRAME");

Serial.print(msgString);

} else {

for(byte i = 0; i<dlc; i++){

sprintf(msgString, " 0x%.2X", rxBuf[i]);

Serial.print(msgString);

}

}

Serial.println();

}

/* Every 1000ms (One Second) send a request for PID 00 *

* This PID responds back with 4 data bytes indicating the PIDs *

* between 0x01 and 0x20 that are supported by the vehicle. */

if((millis() - prevTx) >= invlTx){

prevTx = millis();

if(CAN0.sendMsgBuf(FUNCTIONAL_ID, 8, txData) == CAN_OK){

Serial.println("Message Sent Successfully!");

} else {

Serial.println("Error Sending Message...");

}

delay(500);

if(CAN0.sendMsgBuf(FUNCTIONAL_ID, 8, txData1) == CAN_OK){

Serial.println("Message Sent Successfully!");

} else {

Serial.println("Error Sending Message...");

}

}

}