For my current project, I would like to measure the voltage of a high voltage capacitor while it is charging from the power supply, so I know that I will have to disconnect the power supply whenever I would like to measure the cap voltage. However, I am unsure how to measure this high voltage into the arduino, because you cant run more than 5 volts through the arduino, and any attempt to run the capacitor through a voltage divider would just drain the capacitor instantly. How would I go about monitoring its voltage?

Zoltakk:

For my current project, I would like to measure the voltage of a high voltage capacitor

How high voltage?

How big a capacitance?

Why can't you simply time the charging? It's a capacitor after all...

any attempt to run the capacitor through a voltage divider would just drain the capacitor instantly

Then don't use 1-2 Ohm resistors. Use something more sensible, like 10-100k. It'll save you having to replace burnt out resistors all the time as well.

You can use this site http://www.ohmslawcalculator.com/voltage-divider-calculatorhttp://www.ohmslawcalculator.com/voltage-divider-calculator to figure out differing resistor combinations. I'd, in this case, would go for high resistor values starting with what's been mentioned.

Or re-arrange your circuit configuration, so that there is no need to disconnect the capacitor from the power supply.

This may necessitate you to have the Arduino battery powered and allowed to float to some high voltage.

You need to tell us how high this voltage is, before we can make properly informed assistance.

Charge it from a constant current and measure the voltage whilst it charges.

Use an op-amp with FET inputs to buffer the voltage divider so the discharge is negligible.

All of these points are very helpful! The capacitors I am currently looking at for my project are 200V 1000uF. I will definitely use stronger resistors to limit the current passing through the voltage divider to minimize the loss of charge in the capacitors. However, some of you mentioned that it is possible to monitor the capacitor's voltage while it was charging, and I did not know that this was possible. I cant figure out a way to do this because when I try to measure the capacitor while its charging, I just measure the voltage of the power supply that is charging the capacitor. How could I accomplish this?

Do give more information on your exact charging circuit. A schematic preferably.

To measure 200V you best use a 1:200 voltage divider (bring down the voltage to <1V, use the internal reference). Standard values 10k and 2M2 will do nicely. Or 10K on the low side, and 2x 1M on the high side. This way you can easily follow the voltage on the capacitor's terminals as it charges (can't tell how much or if any different that will be from the power supply's output voltage).

This resistance is so high you likely won't notice the effect during charging; after charging you will see the voltage go down slowly, RC = 2,000 seconds, just over half an hour to lose 70%. So just don't leave it connected.

Of course utmost care must be taken, 200V DC is seriously lethal.

Zoltakk:

and any attempt to run the capacitor through a voltage divider would just drain the capacitor instantly.

Not true. 470k:10k will work with a discharge time-constant of 8 minutes,

4.7M:100k will work with a time constant of over an hour,

47M : 1M will work with 12 hourse or so

Resistors don't have strength, they have resistance and power handling and maximum voltage. For 200V you

have to avoid the smallest 1/8thW resistors as they don't have the voltage rating.

I'd recommend 2.2M + 2.2M : 100k. Two series resistors on the high voltage side removes a single point

of failure.

With these high impedances of resistive divider you might have to read the analog voltage twice in a row

to allow enough settling time in the ADC.

Note that 1000µF at 200V is definitely a killer, respect those high voltages, there are no second chances.

The capacitors I am currently looking at for my project are 200V 1000uF.

Never charge a 200V working capacitor to 200V, the maximum voltage you should use on a capacitor should be only around 80% of the working voltage anyway.

So why do you actually want to measure this? It is not like it will change overly much.

The charge time will be limited by the impedance of your power supply acting as a series resistor, that is why measuring across the capacitor gives you the current state of charge of the capacitor and not the voltage from the charging circuit.

If you want to slow this down then add an extra series resistor, but you still measure across the capacitor.

Hi,

Can you please post a copy of your capacitor charging circuit, in CAD or a picture of a hand drawn circuit in jpg, png?

We need to see how you have your capacitors configure with respect to gnd and how you are charging them, then we can give you advice on how to safely monitor the capacitor voltages.

Thanks.. Tom... ![]()

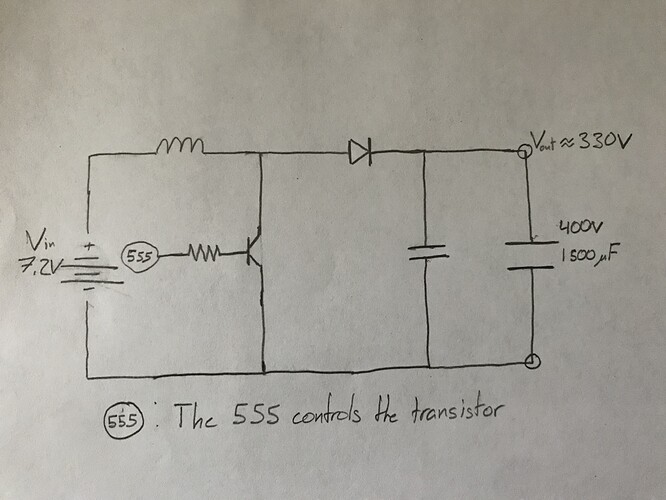

The capacitors I am now using are rated at 400V 1500uF, and I am charging them with a boost converter circuit that inputs with 7.2V, and outputs about 330V to charge the capacitor. I am controlling the transistor that feeds current to the capacitor with a 555 timer. The circuit diagram is included below.

Is there a safe way to read the charging voltage of the 400V capacitors through the arduino nano?

Hi,

OPs diagram.

Have you got this circuit working?

What are the component values and transistor part number.

The circuit does not show 1000uF 200V, is this your circuit?

Do you have a DMM?

Thanks.. Tom...

Zoltakk:

The capacitors I am now using are rated at 400V 1500uF, and I am charging them with a boost converter circuit that inputs with 7.2V, and outputs about 330V to charge the capacitor. I am controlling the transistor that feeds current to the capacitor with a 555 timer. The circuit diagram is included below.Is there a safe way to read the charging voltage of the 400V capacitors through the arduino nano?

If you are using a transistor to control current, it needs to be in series with the charging current, not in parallel, like the schematic shows.

Paul

Hi,

I think the OP is trying to make a boost converter.

Tom.... ![]()

Impressive to get 330V with such a simple circuit (looks indeed like a boost converter to me).

to measure such voltages: a good old voltage divider will work, but do put two resistors in series to prevent sparks jumping over, and for the same reason use the larger THT parts: two 6.3 mm resistors should be safe. Just don't touch anything, and place it behind a protective screen just in case it does explode.

You also need to use quite high values in your voltage divider to stop excessive drain of the circuit because that circuit will not supply much current. Something in the 1M region, but that will mean the measurements won’t be as responsive so you definitely need to use the measure twice and use the second reading method.

Grumpy_Mike:

you definitely need to use the measure twice and use the second reading method.

Only so if switching ADC channels.