Uploading: image.jpg...

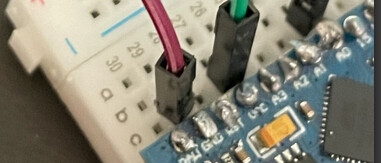

I’m sorry, here is a picture of the whole thing. The plastic is a little melted but it should still flow a current.

Bad image link. At least, on this end...

The plastic is a little melted but it should still flow a current.

TBH, that does not sound encouraging.

Start with quality solder

Your pots all have metal covers. Bend the tabs back, remove the cover and examine the insides. Should be NO debris, and NO discoloration on the resistor track and no marks on the track. either.

Another soldering fail. You can buy components on modules with header pins. That is the direction you will have to take.

Hi, to me it looks like not enough heat and too quick, unless solder is bad.

Can you post an image(s) of your solder and soldering iron?

Thanks... Tom... ![]()

![]()

![]()

![]()

The pins of those DuPont wires are not ment to be soldered.

They are meant to be put in breadboards or headers.

You should cut them off (or cut them in half), strip the wire, twist the tiny copper wires that are visible now. And then tin. The solder should flow not blob...

Copper has a red/brown shiny color....

Freshly tinned copper should be shiny (almost like silver) but more greyish.

check the solderings

Its in my garage, but here is the link to the amazon page

The roll of solder has no useful information on it, so it could be anything.

My advice is to not use it for electronics.

Buy a roll (or small tube) where it clearly states Sn63/PB37 rosin core, and if possible RMA.

Leo..

That solder is high heat solid core. Not the correct solder for electronics work. The rest of the kit seems usable. From reading reviews the tip wants to run a bit cold. Use the wedge tip set at 360C - 380C once you get the proper solder. You will notice a huge improvement.

10k resistor in series with blue wire and 1uF (10uF ) capacitor A0 to ground.

Put oscilloscope on A0

bought it few months ago (same model, temperature choice etc...) with a cool box to put all accessories.

It has last.... 5 min.

I kept the box and bought another model in a shop nearby. Still in function.

Thanks amazoning for this super choice of high quality grade material!

Price must have been a clue. Let's say I dunno how to use (to choose!) an iron!

A 60W iron is way, way overpowered for PCB electronics use. Edit - wait, it's temperature controlled. Then, back to methodology, training and skill.

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.