Hey guys,

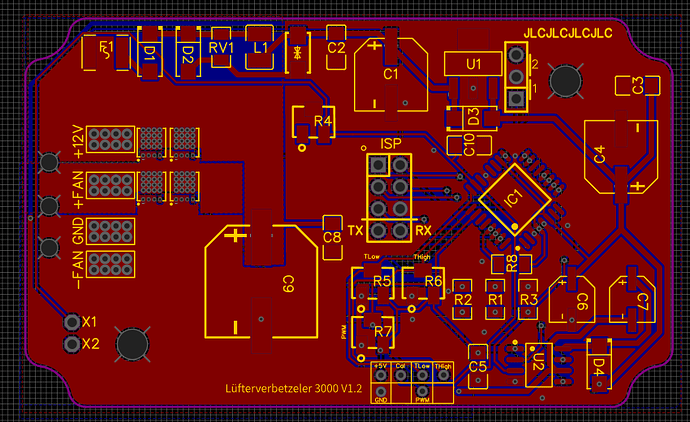

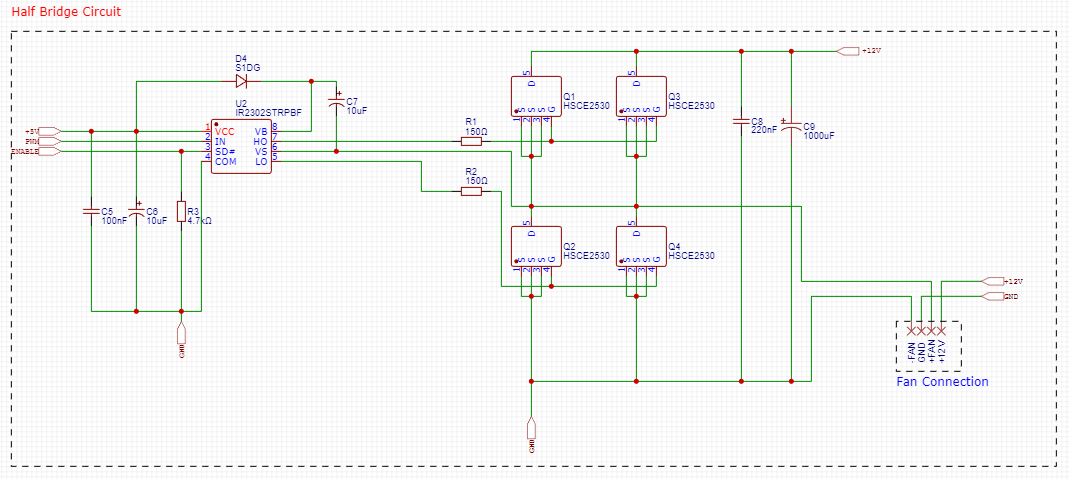

Currently I´m working on a circuit board for controlling a fan depending on temperature (in my case for a car or bike etc.).

The design and code derives from a project I have done in the past, which is working flawlessly until now.

For the new design I just added a pin header to switch between different modes and changed to a different MOSFET, because the availability of the old one became terrible.

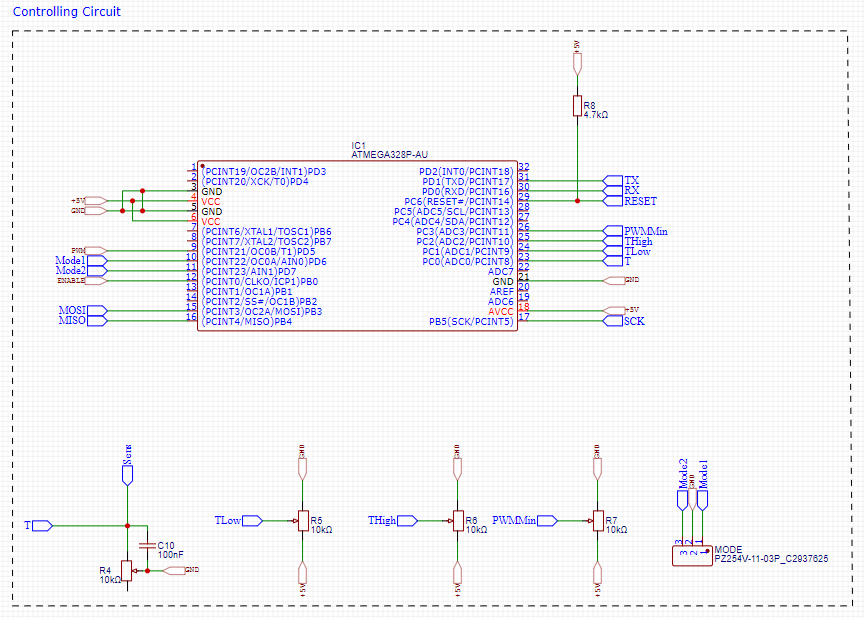

I´m using an Atmega328P with internal clock at 8MHz, programmed by an Arduino Uno as ISP, which I use for debugging (reading data from the Atmega and sending it to my PC via Serial).

So in theory everything should work fine if you started from a known, working design... but it doesn´t.

I encountered two problems:

The first problem is that the pulldown resistor (R3) is not working. By that I mean no matter how big the value is, the Atmega is not able to pull the pin of the bridge driver high to enable it.

I tried values from 4.7k to 47k, but no difference. So I started to look after errors in my code regarding the logic and inversed it. Still no difference. I´m really scratching my head now, because this part of the pcb/code was working in the old design.

The second problem that the MOSFETs and the capacitor (C9) are getting really really hot after a short time. I run an old, small fan of a 3D-printer hot end for testing. My old design is capable of around 20A and is running very cool under these conditions.

Sadly, I can´t find the code of the old Arduino project....

Here is my code (still under construction ![]() ) and I attached pictures of my schematic/PCB)

) and I attached pictures of my schematic/PCB)

//Defining Pins

#define TPin PC0

#define TLowPin PC1

#define THighPin PC2

#define PWMMinPin PC3

#define PWMOutPin PD5

#define Mode1Pin PD6

#define Mode2Pin PD7

#define EnablePin PB0

//Constants

const int ntc_nom = 5000;

const int PWMMax = 255;

//Variables for temp measurement

float TRaw = 0;

float TU = 0;

float TR = 0;

float T = 0;

//Variables for parameters

int TLow = 0;

int THigh = 0;

int PWMMin = 0;

int PWMOut = 0;

int Mode1 = false;

int Mode2 = false;

int FanState = 0;

//This makes printing values much easier (for debugging)

void printValue(String text, float value, String text2 = "");

void setup() {

//Pin setup

pinMode(TPin, INPUT);

pinMode(TLowPin, INPUT);

pinMode(THighPin, INPUT);

pinMode(PWMMinPin, INPUT);

pinMode(PWMOutPin, OUTPUT);

pinMode(Mode1Pin, INPUT_PULLUP);

pinMode(Mode2Pin, INPUT_PULLUP);

pinMode(EnablePin, OUTPUT);

Serial.begin(9600);

//Reading the potentiometers to get the parameters and mapping them to fixed values

TLow = analogRead(TLowPin);

TLow = map(TLow, 0, 1023, 0, 120);

THigh = analogRead(THighPin);

THigh = map(THigh, 0, 1023, 0, 120);

PWMMin = analogRead(PWMMinPin);

PWMMin = map(PWMMin, 0, 1023, 0, 255);

//Turning off the mosfet driver at startup

digitalWrite(EnablePin, LOW);

}

void loop() {

//Reading the mode pins to choose the mode

Mode1 = digitalRead(Mode1Pin);

Mode2 = digitalRead(Mode2Pin);

//Mode 1

if(Mode1 == 0 && Mode2 == 1) {

//Getting the temperature

TRaw = analogRead(TPin);

TU = TRaw * 5 / 1023;

TR = ntc_nom * (5 / TU - 1);

T = -28.42 * log(TR) + 234.33;

//Turning fan on when TLow is reached and setting PWM signal according to the parameters

if(T >= TLow){

PWMOut = map(T, TLow, THigh, PWMMin, 255);

PWMOut = constrain(PWMOut, PWMMin, 255);

analogWrite(PWMOutPin, PWMOut);

digitalWrite(EnablePin, HIGH);

FanState = 1;

}

//If temperature drops below TLow the fan is switched off

else{

analogWrite(PWMOutPin, 0);

digitalWrite(EnablePin, LOW);

FanState = 0;

}

//Debugging

Serial.println("MODE 1");

printValue("T: ", T);

printValue("TLow: ", TLow);

printValue("THigh: ", THigh);

printValue("PWMMin: ", PWMMin);

printValue("Mode1: ", Mode1);

printValue("Mode2: ", Mode2);

printValue("PWMOut: ", PWMOut);

printValue("FanState: ", FanState);

Serial.println();

delay(1000);

}

//Mode 2

if(Mode1 == 1 && Mode2 == 0){

analogWrite(PWMOutPin, 200);

digitalWrite(EnablePin, HIGH);

FanState = 1;

//Debugging

Serial.println("MODE 2");

printValue("T: ", T);

printValue("TLow: ", TLow);

printValue("THigh: ", THigh);

printValue("PWMMin: ", PWMMin);

printValue("Mode1: ", Mode1);

printValue("Mode2: ", Mode2);

printValue("PWMOut: ", PWMOut);

printValue("FanState", FanState);

Serial.println();

delay(1000);

}

//Mode 3

if(Mode1 == 1 && Mode2 == 1){

//coming soon

}

}

void printValue(String text, float value, String text2 = "") {

Serial.print(text);

Serial.print(value);

Serial.println(text2);

}