Can I convert a servo motor into an angle sensor. My logic is that the servo motor must have an idea of where it is pointing, so can I read this value and print it to the console. Thanks in advance

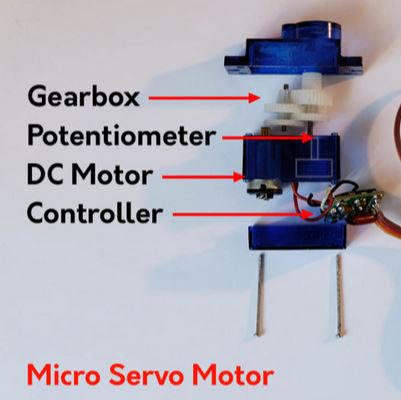

Inside the servo, a potentiometer attached to the servo output shaft gives a direct readout of the servo arm angle. You could take the servo apart, remove the controller and motor, and read out arm position (the pot value) using an Arduino.

The potentiometer does not cover the full 360 degrees, so to measure shaft angles a shaft encoder is typically used.

Shaft encoders come in two types: absolute angle (expensive) and relative angle, which requires zeroing at startup.

So I assume that my hypothesis is correct. Is there a way to read out the angle in code ( I don’t need full 360 degrees, I just want to know where it is pointing, so for a servo motor that turns 180 degrees and I manually rotate it to point in the middle, the code should read out 90). Also is there a method to do this without purchasing anything

The search phrase "arduino read potentiometer" will turn up tutorials.

a method to do this without purchasing anything

That depends on whether you have everything needed.

I have a servo and an arduino

I believe I have been misunderstood. Usually, when I have to tell a servo motor to turn toward a particular direction, I have to brute force and try inputting various angles into the

Servo.write(angle);

function. Rather than randomly guessing the angle, I want to manually rotate the servo motor’s spiny thing to point wherever I want and then read out the angle so I can input that angle into the servo.write of my actual code. I was hoping for a way to do this without any extra equipment except for the servo, arduino and wires(duh)

Instead of brute force, try making measurements and use simple geometry to estimate the required servo arm angle. Some servos can be destroyed by manually forcing the position.

To read out the arm position as I described above, the servo has to be disassembled and modified. It won't work as a servo without reassembly.

For informed help, please read and follow the directions in the "How to get the best out of this forum" post. Forum members will be happy to help if you explain the problem(s) clearly.

To read out the arm position as I described above, the servo has to be disassembled and modified. It won't work as a servo without reassembly

I do not agree because in my experience when I manually rotate a servo to point in a direction then tell it to point somewhere else via code, the function is aware too where the servo is pointing and it turns accordingly. If somewhere in the inner workings of the Servo.write() function it is able to read the angle of the servo motor, then why can’t I read it

Yes, you can use a servo motor as an angle sensor, depending on the type. Standard hobby servos have a built-in potentiometer for position feedback, which you can tap into. By reading its voltage with an ADC (Analog-to-Digital Converter) on a microcontroller like Arduino, you can get an approximate angle.

However, this won’t work for continuous rotation servos, as they lack positional feedback. If you need more accuracy, a rotary encoder might be a better choice. Let me know your servo model, and I can suggest a more specific approach!

The servo class returns the last value written to the servo and don´t reads the pot of the servo back.

the signal to the servo is one way

there is no way to read the current servo pot position without additional hardware

No, it is not aware of anything. The function sets the output pulse to the servo to make it go to a certain angle; all the servo electronics "knows" is that the servo is not at the right position and it moves it towards the correct new position and stops when it gets there.

The Servo can say where it is, but all that can tell you is what you told it to go last time… the software has no idea where the servo is positioned. It can't even say that there is in fact any servo attached.

I don't think it would be especially hard to open the servo and grab a lead off the wiper of the feedback potentiometer. It will def have a value between 0 and 5 volts, assuming a five volts power supply, and whatever you read will be in proportion to the angle you've twisted in.

Read the voltage at the wiper of the feedback pot with analogRead().

a7

You could write a simple sketch that moved the servo, perhaps with a few buttons to go CW and CCW by big steps and little steps to get the numbers you need. It could print out the angle (or pulse duration) as you proceeded.

Or:

Many programs with such a need implement a calibration function, where you would position the arm and then say you had; the sketch would then use those numbers. No need to squint at the serial monitor window or risk dropping a digit when you carefully write down and type in those numbers.

Use the EEPROM to store the values developed in the calibration. Calibration could be something you have a special trigger to get into. Just a button dedicated to it even.

I go out of my way to avoid copying numbers and typing them again. ![]()

a7

you could wire the Arduino to the pot in a servo with the motor removed to measure the position of an externally moved servo arm

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.