Circuit Prototyping Construction

A new user eventually asks: “Now that I have made my circuit work on a solderless breadboard, how do I make it permanent.”

-

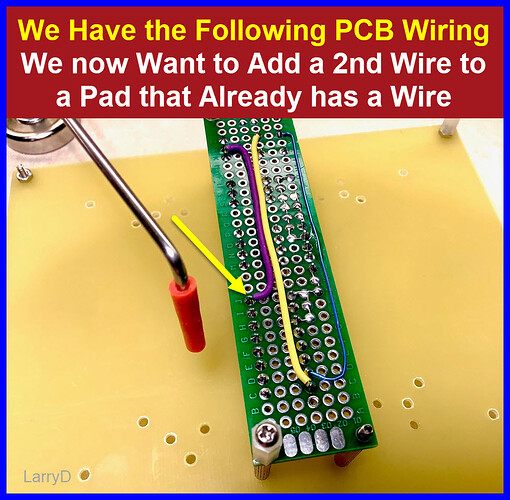

The following images show a technique I use to make a one time, Point-to-Point circuit on a prototyping PCB.

This is a valid way of wiring up a project circuit board; when you need to make several such circuits, it might be time to get PCBs made.

If others have additional suggestions they can pass on, please do. -

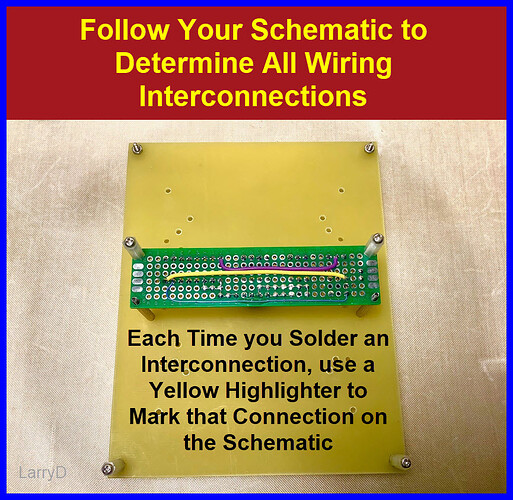

The first thing we need is a schematic showing ALL the electrical connections in our project.

-

Flux will help during soldering.

-

After we solder a wire connection, use a Highlighter to mark that connection on the schematic.

-

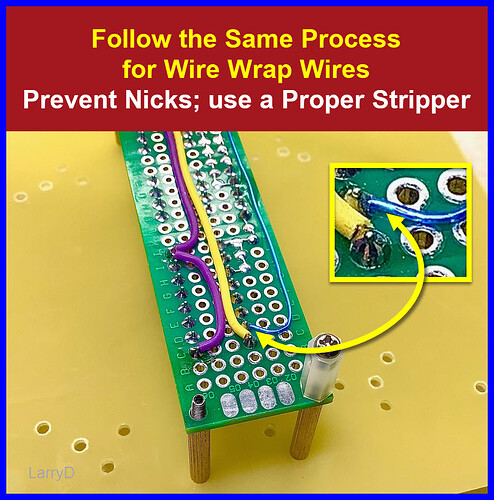

Highly recommend you use heat resistant Kynar insulated 30AWG wire wrap wire, and/or 16 strand, 28AWG Silicone insulated wire.

-

Use a proper non-nicking stripper when removing insulation from wire wrap wire.

-

Strip, twist and tin stranded wire.

-

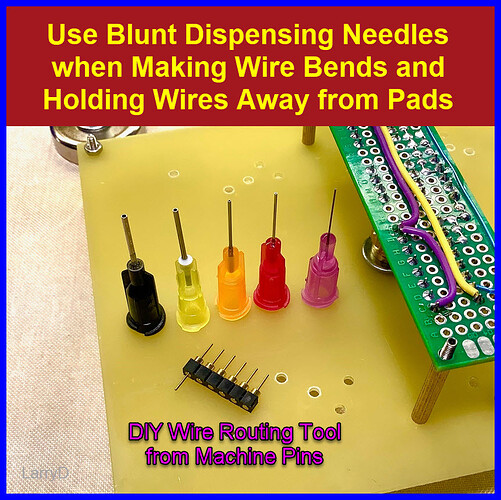

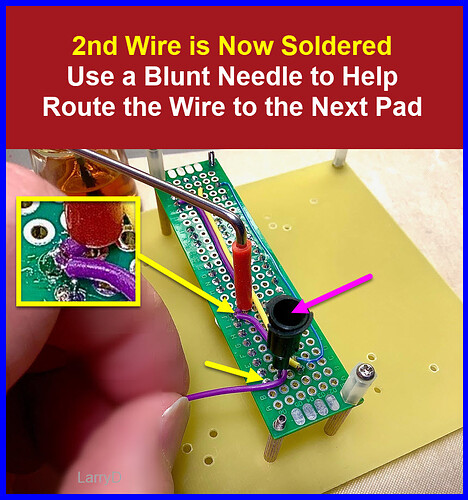

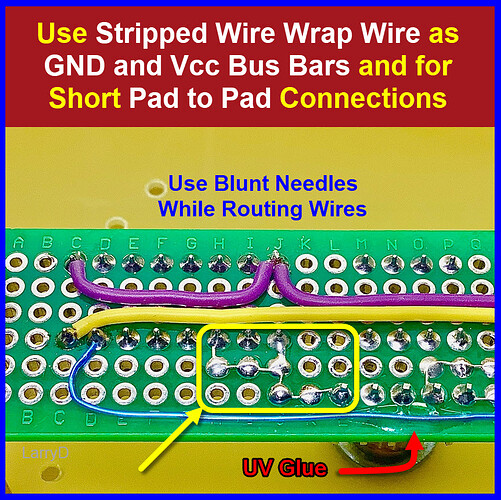

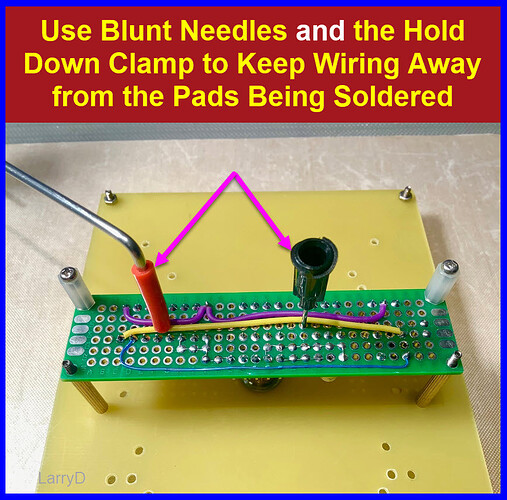

Use Blunt Dispensing Needles when routing wires.

-

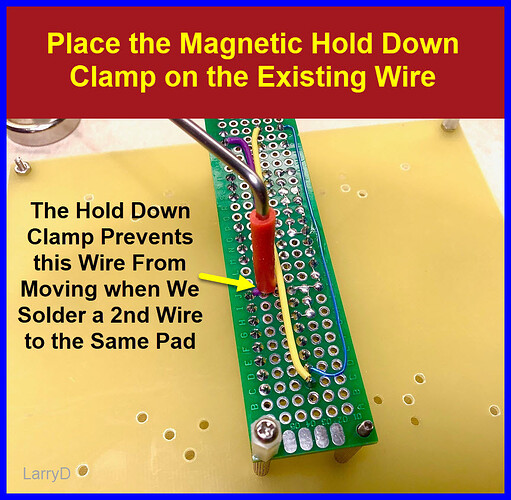

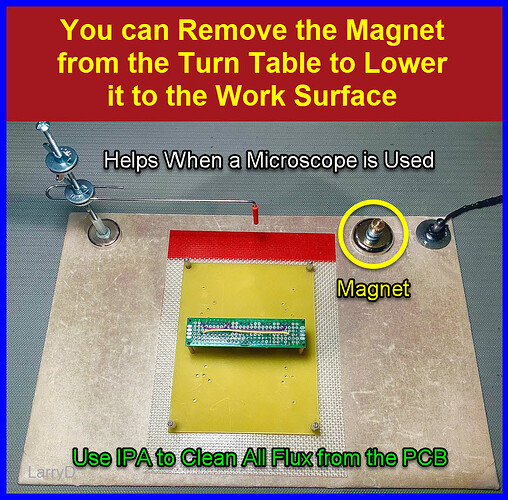

The Magnetic Hold Down Clamp is a must have tool to stop wire movement while soldering. The bend on this tool seems to work best when set to ~93°.

-

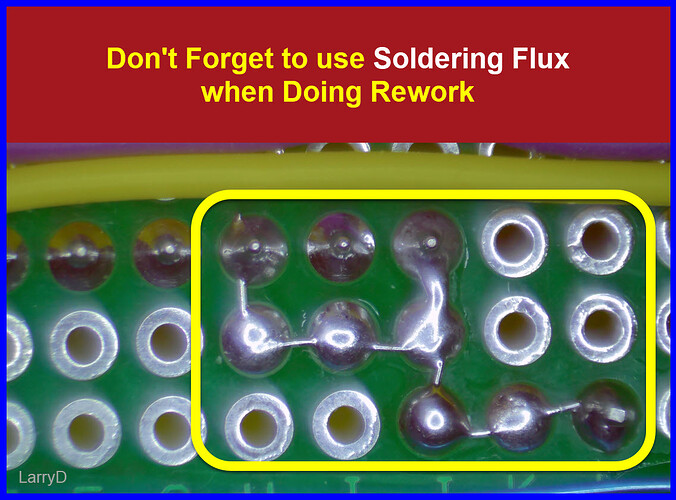

If there is excess solder on a pad, it will be more difficult to make your wire connections. Remove the excess with Solder Wick.

-

Aim for no more than 2 stranded wires per pad, 3 for wire wrap wire.

The Hold Down tool is indispensable when attaching multiple wires to a single pad. -

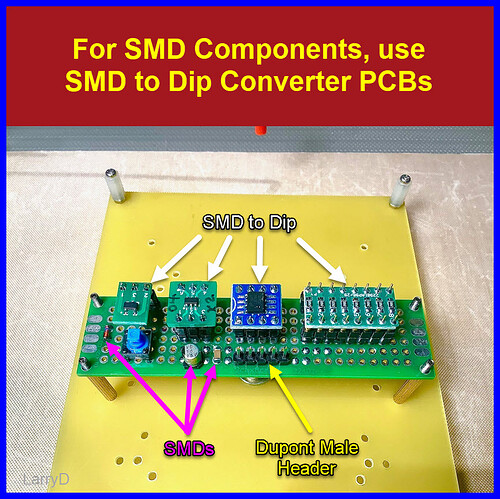

Inexpensive SMD to DIP conversion PCBs are a real help when today’s SMD components are used.

-

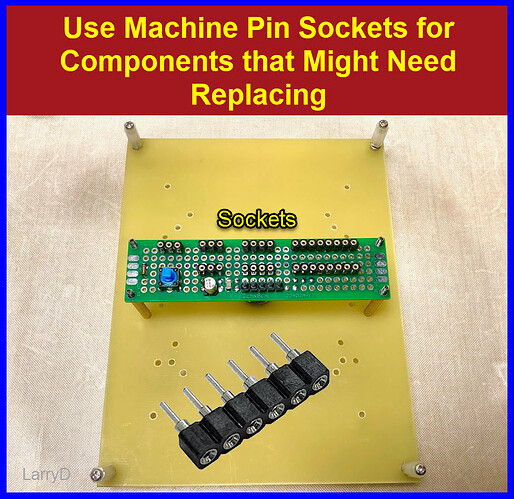

Machine pin sockets should be used if there is a possibility of device failure.

-

Keep Components on one side, wire connections on the other.

-

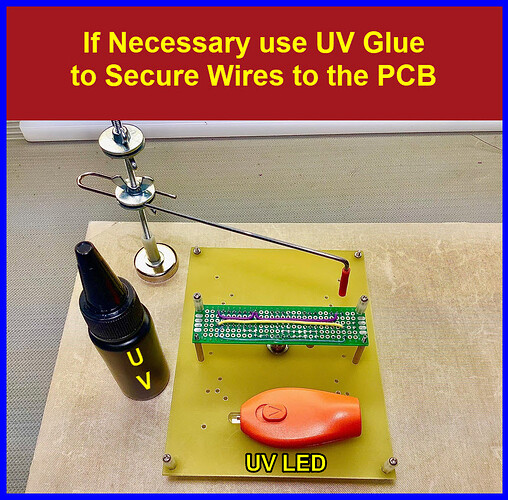

If the need arises, use UV glue to secure wires to the PCB.

-

Off board wire connections should be made using Dupont or JST connectors.

-

Recommended tools in this discussion

1 Tall Magnetic Hold Down Clamp

2 Spring Clamp for tinning wires

3 Sharp hobby knife to cut excess wire wrap wire after soldering

4 Knipex Pliers for holding wire wrap wire while stripping

5 45° Tweezers

6 Sharp Awl

7 Wire Wrap Wire Stripper, non nicking

8 Flush Cut Nippy cutters

9 Wire Wrap Wire with Cutter and Stripper

10 Blunt Dispensing Needles for routing wires

11 DIY wire routing tool

-

Use Magnification to confirm all joints are properly soldered.

If rework is required, make sure you use soldering flux. -

Use a soft toothbrush to clean the PCB , use IPA (Isopropyl Alcohol)