#Blind Standoffs

I do not like to drill holes in a chassis for mounting PCBs.

Doing so, means screw heads are visible from the outside chassis surface.

I mount PCBs using plastic nuts glued/welded to the inside surface of a chassis.

These nuts are usually made from 3mm thick acrylic plastic.

When the PCB is not meant to be removed too often, I usually thread the plastic nuts to an M2 or a 2-56 screw thread.

When PCBs are needed to be removed, I use brass inserts that are installed into the plastic nuts.

These inserts are long lasting, inexpensive and easy to use.

As an alternative to brass inserts, I use M2 knurled brass standoffs.

You can see the physical differences between inserts and standoffs below.

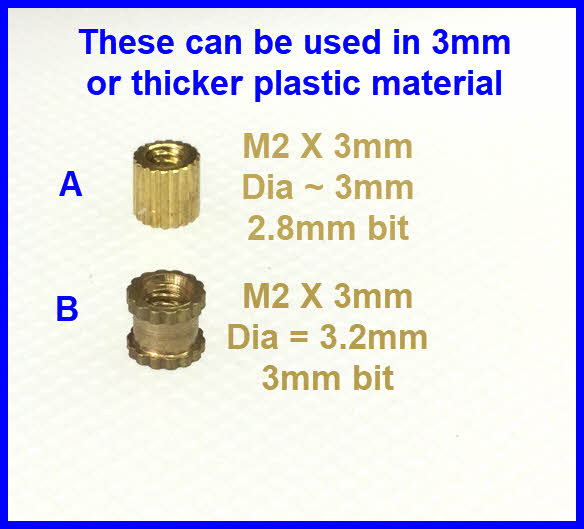

The inserts must be used in material that is equal to or thicker than the insert’s length.

Standoffs can be used in material that is thinner than the standoff’s length.

Below is the method I use to make the plastic nuts.

I show standoffs in the following images, the process for using inserts is the same.

Note:

The 15mm and 20mm standoffs are threaded only 5mm from either end.

A = Brass standoff

B = Brass insert