yes i am on breadboard using LED to test my Logic but by looking at the program everything looks according to logic but on breadboard output is not right at all.

Logic looks odd to me. If you see LOW on the low sensor you turn on the pump. LOW on the high sensor turns it off. What does that do for you if the reservoir is entirely empty? I'd guess that the low water sensor reading will be HIGH, so the pump isn't turned on.

If the water level is lower than the float switch, is the switch OPEN (OFF) or CLOSED (ON)?

Your code appears to be one of each.

here i am using D1 and D2 input_pullup D1 high D2 high means tank is completely empty here case no.1 when pump suppose to start

if water is lower then the sensor then float will return high value

So the switches are normally OPEN, the pullup resistor makes the input HIGH. When water rises and closes the switch, it pulls the input LOW.

If both floats are low, pump should start and stay on even if the bottom switch goes LOW, until the top switch goes LOW. That is not how I read your code.

#include <ESP8266WiFi.h>

// Digital input pin definitions

const int D1_PIN = D1;

const int D2_PIN = D2;

const int D6_PIN = D6;

// Digital output pin definitions

const int D3_PIN = D3;

const int D4_PIN = D4;

// Relay activation durations (in milliseconds)

const int D3_ON_DURATION = 2000; // 2 seconds

const int D4_ON_DURATION = 1000; // 1 second

void setup() {

Serial.begin(115200);

// Set D1 and D2 as input pins with internal pull-up resistors

pinMode(D1_PIN, INPUT_PULLUP);

pinMode(D2_PIN, INPUT_PULLUP);

// Set D3 and D4 as output pins

pinMode(D3_PIN, OUTPUT);

pinMode(D4_PIN, OUTPUT);

// Set D6 as input pin

pinMode(D6_PIN, INPUT);

// Initialize D3 and D4 as low initially

digitalWrite(D3_PIN, LOW);

digitalWrite(D4_PIN, LOW);

}

void loop() {

// Read the input status of D1, D2, and D6

int d1Status = digitalRead(D1_PIN);

int d2Status = digitalRead(D2_PIN);

int d6Status = digitalRead(D6_PIN);

// Print the status of D1, D2, D3, D4, and D6 on the serial monitor

Serial.print("D1: ");

Serial.print(d1Status);

Serial.print(" | D2: ");

Serial.print(d2Status);

Serial.print(" | D3: ");

Serial.print(digitalRead(D3_PIN));

Serial.print(" | D4: ");

Serial.print(digitalRead(D4_PIN));

Serial.print(" | D6: ");

Serial.println(d6Status);

// Check the truth table conditions and perform the corresponding actions

if (d1Status == HIGH && d2Status == HIGH && d6Status == HIGH) {

digitalWrite(D3_PIN, HIGH); // Turn on D3

delay(D3_ON_DURATION); // Wait for 2 seconds

digitalWrite(D3_PIN, LOW); // Turn off D3

digitalWrite(D4_PIN, LOW); // Keep D4 low

} else if (d1Status == LOW && d2Status == HIGH && d6Status == HIGH) {

digitalWrite(D3_PIN, LOW); // Turn off D3

digitalWrite(D4_PIN, LOW); // Keep D4 low

} else if (d1Status == LOW && d2Status == LOW && d6Status == HIGH) {

digitalWrite(D3_PIN, LOW); // Turn off D3

digitalWrite(D4_PIN, HIGH); // Turn on D4

delay(D4_ON_DURATION); // Wait for 1 second

digitalWrite(D4_PIN, LOW); // Turn off D4

} else if (d6Status == LOW) {

digitalWrite(D3_PIN, HIGH); // Turn on D3

delay(D3_ON_DURATION); // Wait for 2 seconds

digitalWrite(D3_PIN, LOW); // Turn off D3

}

// Add a delay to prevent continuous checking

delay(1000);

}

please go through my code even this is not working as given truth table

You may get some idea from the following Arduino UNO based two pump system.

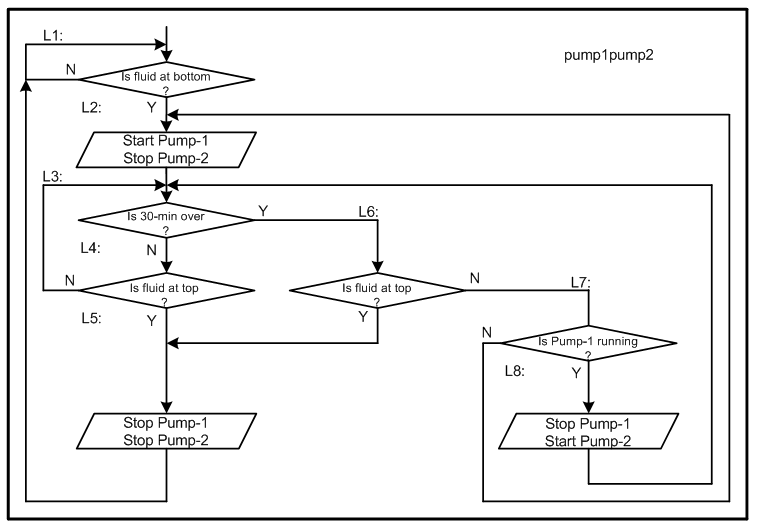

Figure-1:

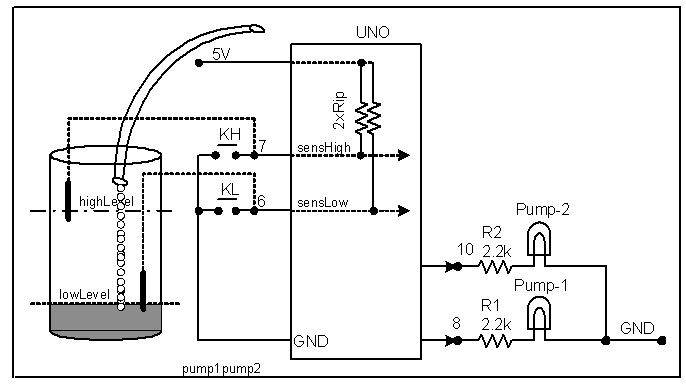

Figure-2:

Algorithm:

(1) When fluid level is at Bottom (equivalent to closing button KL switch), Pump-1 will start.

(2) When fluid level is at Top (equivalent to closing button KH) Pump-1 stops.

(3) When fluid level is at Top and Pump-1 has run for 30-min, Pump-1 stops.

(4) When fluid level is not at Top but Pump-1 has run for 30-min, Pump-1 stops and Pump-2 starts.

(5) When fluid level is at Top (equivalent to closing button KH) Pump-2 stops.

(6) When fluid level is at Top and Pump-2 has run for 30-min, Pump-2 stops.

(7) When fluid level is not at Top but Pump-2 has run for 30-min, Pump-2 stops and Pump-1 starts.

(8) Goto Step-2.

Sketch-1: The following sketch prepared using goto statement for easy understanding and quick development of the program. In programming, the use of goto statement is highly discouraged. In Sketch-2, the goto statement is removed. In Sketch-1, the time delay is 8-sec (for test purpose) and it has been created using TC1 of the MCU. The program senses the end of time delay on interrupt basis.

#define sensLow 6

#define sensHigh 7

#define Pump1 8

#define Pump2 10

bool p1On = false;

bool p2On = false;

volatile bool runTimeIsOver = false;

volatile int irqCounter = 0;

void setup()

{

pinMode(8, OUTPUT);

pinMode(10, OUTPUT);

pinMode(sensLow, INPUT_PULLUP);

pinMode(sensHigh, INPUT_PULLUP);

//-------------------------------

TCCR1A = 0x00;

TCCR1B = 0x00;

TCNT1 = 3036; //for 4-sec time dealt with 1024 prescaler

TCCR1B = 0x05;

bitSet(TIMSK1, TOIE1);

}

void loop()

{

L1: if (digitalRead(sensLow) == LOW)

{

L2: digitalWrite(Pump1, HIGH);

p1On = true;

digitalWrite(Pump2, LOW);

p2On = false;

L3: if (runTimeIsOver == true)

{

runTimeIsOver = false;

goto L6;

}

L4: if (digitalRead(sensHigh) == HIGH)

{

goto L3;

}

L5: digitalWrite(Pump1, LOW);

p1On = false;

digitalWrite(Pump2, LOW);

p2On = false;

goto L1;

L6: if (digitalRead(sensHigh) == LOW)

{

goto L5;

}

L7: if (p1On == false)

{

goto L2;

}

L8: digitalWrite(Pump1, LOW);

p1On = false;

digitalWrite(Pump2, HIGH);

p2On = true;

goto L3;

}

}

ISR(TIMER1_OVF_vect)

{

TCNT1 = 3036; //4-sec time delay parameter at prescaler 1024

irqCounter++;

if (irqCounter == 2)//8-sec delay

{

runTimeIsOver = true;

irqCounter = 0;

}

}

Sketch-2:

Converting Flow Chart of Fig-2 into Control Codes/Sketch without goto statement and using millis() function for time delay.

#define sensLow 6

#define sensHigh 7

#define Pump1 8

#define Pump2 10

unsigned long prMillis = 0;

bool pump1State = LOW;

bool pump2State = LOW;

void setup()

{

pinMode(8, OUTPUT);

pinMode(10, OUTPUT);

pinMode(sensLow, INPUT_PULLUP);

pinMode(sensHigh, INPUT_PULLUP);

while (digitalRead(sensLow) != LOW)

{

; //wait until fluidLevel falls at Bottom

}

pump1State = !pump1State;

digitalWrite(Pump1, pump1State); //on

}

void loop()

{

prMillis = millis();

while (millis() - prMillis < 5000ul) //5-sec test interval

{

if (digitalRead(sensHigh) == LOW)

{

digitalWrite(Pump1, LOW); //on

digitalWrite(Pump2, LOW); //on

while(digitalRead(sensLow) != LOW)

{

; //wait until fluidLevel falls at Bottom

}

break; //turn on the next Pump in sequence

}

}

pump1State = !pump1State;

digitalWrite(Pump1, pump1State); //on-off

pump2State = !pump2State;

digitalWrite(Pump2, pump2State); //on-off

}

Here's a basic 1 second ON delay, trigger could be a button press (debounced) or a pulse from a code function.

Pseudocode

if(not timing and trigger)

{

timer = millis();

timing = true;

}

if(millis() - timer > 1000)

{

timing = false;

}

outPin = trigger or timing;

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.