Hi Tom,

The MoQ for a 3V version of the solenoid is 5000/off. The 6V version is off the shelf. Tag accepts 3-6.5V but I was worried about blowing the controller at 6V.

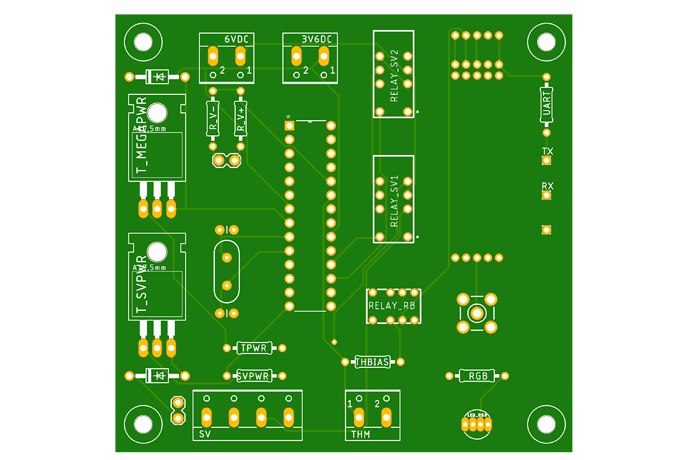

I have not connected the grounds of the 6V & 3V circuits.

The tag sends it's own voltage with each blink/transmission but we need to monitor the 6V cellpack too so RV+ and RV- are the resistors for simple volt monitor.

I used the transistors to avoid pulling too much current on controller/tag output pins.

Transistor 1 (T_SVPWR) completes 6V circuit to apply momentary supply to solenoids (open/close)

Transistor 2 (T_MEGAPWR) is suposed to supply power to controller when the tag output pin goes high.

The grounded collector is likely a mistake by me.

Requirement: receive command from server > start flush sequence > open valve 1 > wait 2 min > record temperature and send to server > close valve 1 & open valve 2 > wait 2 min > record temperature and send > close valves > reboot tag for reset

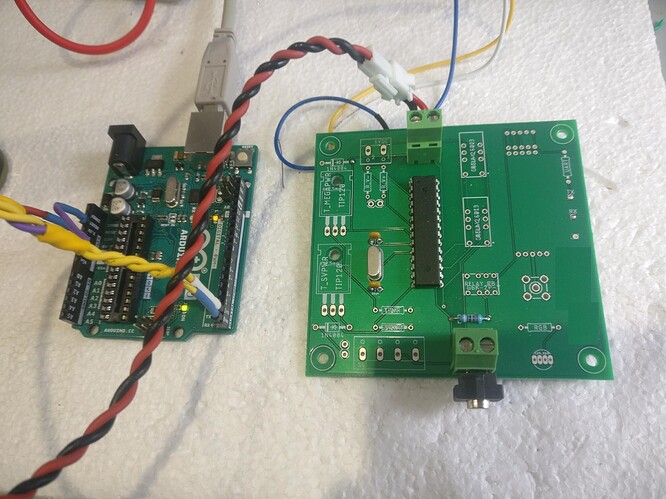

'Tag' refers to RF module (433MHz)

Latching relays are used to configure solenoids, ie switch polarity so when current supplied, they make desired movement.

Thermistor reading sent to tag by serial, no logic applied to result.

Controller is supposed to manage this operation.

This afternoon I have got the thermistor working, well changed the thermistor & bias resistor from 100K to 10K, changed code to deal with negative temp coefficient, and have good readings. Ditched the R lookup table too. This is with all components in place.

Useful comments below guide:

http://www.circuitbasics.com/arduino-thermistor-temperature-sensor-tutorial/

I am still concerned that my lack of knowledge has led to a few no-no's so advice is really appreciated.