I have a TB6612FNG Motor Driver, power supplied by a boost converter from an 18650 battery. The boost converter was set to 11.5V with peak currents of 2A. There are three TT 130 geared brushed motors on each channel with a stall current of 200mA each motor. So there are 6 motors in total and that should only be around 1.2A to be provided to the motor driver. The problem is the the motor driver is only consuming at most of 0.3A, so the motors are very slow and weak. I even installed a heatsink to it, those used on raspi. What could be the cause of this?

As I suggested earlier, save space, weight and reduce complexity by replacing 3 motors with 1 more suitable type.

Please post the full specifications of the motor, preferably a datasheet.

So an expected run current of considerably less than that.

The stall current is the current drawn if you hold the motor still so it can't rotate. Evidently it should be powered for long this way because it may/will burn out the coils. The stall current is necessary to know because it's the peak current the power supply & motor driver will need to momentarily supply when the motor starts.

That sounds about right.

That's probably because (1) it's a slow and weak type of motor and/or (2) you may still have a mechanical problem in how you've linked all three motors together, despite stating earlier that you solved this problem. I'm skeptical about that claim.

That's nice, but evidently doesn't do much unless overheating of the driver was the source of the problem. As I understand it, there was no sign for this.

PS:

It seems your motors are rated for max. 6V. Why boost all the way up to 11.5V?

@noble16dale ,

Topics merged.

Please do not create multiple topics for what is essentially a continuation of the same question / project. If you continue to do so then you risk a suspension form the forum.

Thank you.

Can you elaborate further in this? This is the first I heard of that term.

No problems so far when it comes to the motors apart from weight. Directly powered it with a 9 volt battery and it was working fine. I deduced that the motor driver is the only bottleneck left to fix.

The gears used are herringbone gears. At first it was just spur gears but was met with synchronization and slipping issues.

I agree. The heatsink was barely warm. Sign that there is less current draw.

Tried 5V to 12V (motor driver max V: 13.5) and still weak spins. The current draw were just 0.3A or less.

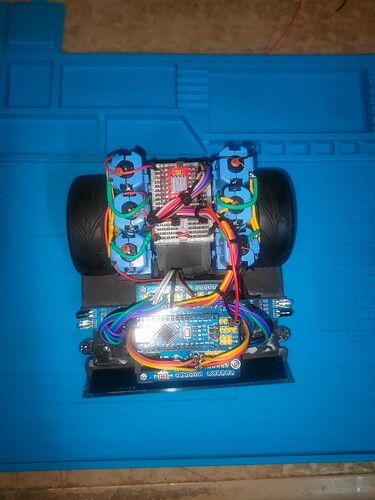

I'm starting to think that all the power supply problems might not be the root of this. It was working fine back when the TB6612FNG was directly powered by two 9V in paralelI, no boost converter. Here's the vid. The code was simple, 5 sec forward and delay.

Lo and behold. It was indeed the motor driver TB6612FNG. Tested the bot with the DRV8833 and it is working fine. Test Vid, the code was copied from gh.

From what we can observe on the vid, on 9V, the activation current on a single channel can be up to 0.7A, then settles to around 0.6A. The DRV8833 has a continuous output current of 1.2A per channel (some says 1.5A), 2A (per channel) peak output current.

Although it is less efficient than the TB6612FNG, it will suffice and I've installed a heatsink.

The 9V will be set aside and it will be powered with an 18650 through a boost converter. Although heavy, it would be beneficial if it was close to 600 grams. Hopefully this is it so I can start programming along with its sensors.

OK, good to hear. How much current do your motors now draw while they run?

https://www.google.com/search?q=motor+run+current+vs+stall+current

If you stall the motor, the current that goes through it works out as the current through the DC resistance of the coil, since there's no transfer of energy between the rotor and the stator. The DC resistance is typically far lower than the AC impedance when the motor runs. Hence, the stall current is much higher.

I note that the datasheet you link to suggests to run the motors at 3-6V. I'm not surprised you get more torque out of them by going 50-100% over that suggested range.

It should be able to run your motors; maybe a connection/configuration problem.

This topic was automatically closed 180 days after the last reply. New replies are no longer allowed.