Magnets have arrived, the ones the data sheet proclaimed, 6mm round and 2.5mm thick diametrically magnetised.

After some time trying, I must still say, the physical adjustment of magnet and sensor is quite difficult.

And I've not really been successful yet, you'll see later.

with a little washer, I think, I've been able to place the magnet relative central on the turning axis.

The sheet where the as5600 is fixed to, allows me to move the sensor in therms of distance between magnet and sensor but also allows me do adjust the centre with the magnet.

I've still not understood what the AGC value really means and how to use it to adjust the sensor and the magnet.

It says that the AGC value has to be 50%, if that means at a certain point (at one point of the 360°) or if it always should be 50%, even when the motor is running (on all points of the 360°), I dont know

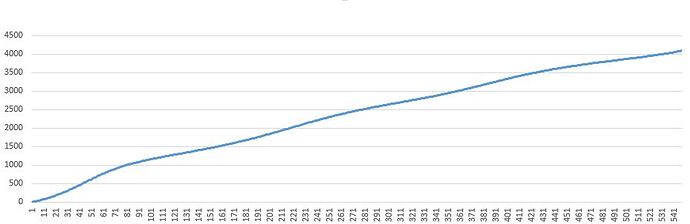

If tested a few settings (meaning places of the sensor in relations to the magnet) but I only get a reading of the diagram of the attachment.

You see, that I dont get a linear reading which obviously means that my sensor is not central to the magnet...

And it also means, that using the value of 0 - 4096 is not linear.

for example, 25% of 4096 would be 1024, but with my readings, 25% of the turn would be with the value of 1381.

not being centred, doesnt make it easier to work with.

If anybody, has a some advice for me on how to adjust the sensor relative to my magnet, I'd be very happy to hear it.