Hi All,

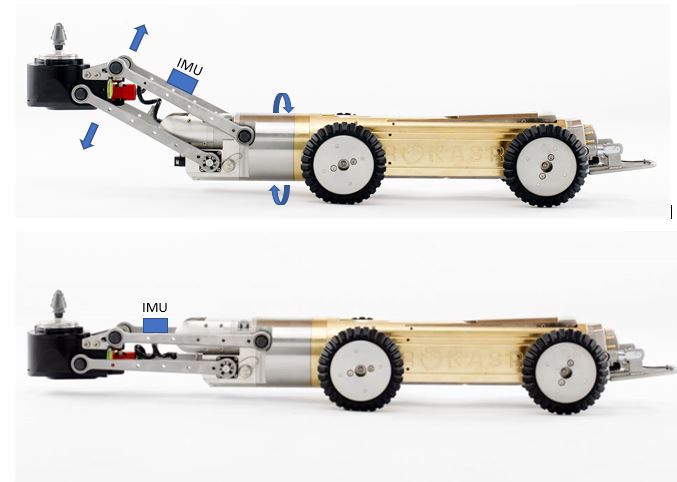

I have a problem managing the absolute angles on a BMI160 IMU sensor , the sensor is connected in i2C to an Atmega2560.

Phisically the board is mounted on an arm that can rotate 360° around IMU X axis and tilt around Y axeis +/- 80°.

The problem I have is that "Roll" angle ( arm rotation) start from 0 and go to +/-90° depending on rotation side and then start decreasing again to 0 , for example a real 100° return 80°, at the same time Pitch angle jump from 0 to something close to 180° when roll pass 90°.

I tried this code that use different type of filters but all the outputs have the same behaviour exept the gyro_roll that measure a full 360 angle but is obviously subject to a big drift overtime.

Someone that face the same problem can help me ?

Thanks in advanced

Flavio

#include <Wire.h>

#include <math.h>

#include <BMI160Gen.h>

#include <Kalman.h>

#include <MadgwickAHRS.h>

#define PRINT_PROCESSING

#define BAUDRATE 115200

#define SENSE_RATE 100

#define GYRO_RANGE 250

#define ACCL_RANGE 2

#define deg_to_rad(a) (a/180*M_PI)

#define rad_to_deg(a) (a/M_PI*180)

Kalman kalmanRoll;

Kalman kalmanPitch;

Madgwick madgwick;

float convertRawGyro(int gRaw) {

// ex) if the range is +/-500 deg/s: +/-32768/500 = +/-65.536 LSB/(deg/s)

float lsb_omega = float(0x7FFF) / GYRO_RANGE;

return gRaw / lsb_omega; // deg/sec

}

float convertRawAccel(int aRaw) {

// ex) if the range is +/-2g ; +/-32768/2 = +/-16384 LSB/g

float lsb_g = float(0x7FFF) / ACCL_RANGE;

return aRaw / lsb_g;

}

static float gyro_roll = 0, gyro_pitch = 0, gyro_yaw = 0;

static float comp_roll = 0, comp_pitch = 0;

static unsigned long last_mills = 0;

void print_roll_pitch()

{

// read raw accl measurements from device

int rawXAcc, rawYAcc, rawZAcc; // x, y, z

BMI160.readAccelerometer(rawXAcc, rawYAcc, rawZAcc);

float accX = convertRawAccel(rawXAcc);

float accY = convertRawAccel(rawYAcc);

float accZ = convertRawAccel(rawZAcc);

float rad_a_roll = atan2(accY, accZ);

float rad_a_pitch = atan2(-accX, sqrt(accY*accY + accZ*accZ));

float accl_roll = rad_to_deg(rad_a_roll);

float accl_pitch = rad_to_deg(rad_a_pitch);

// read raw gyro measurements from device

int rawRoll, rawPitch, rawYaw; // roll, pitch, yaw

BMI160.readGyro(rawRoll, rawPitch, rawYaw);

float omega_roll = convertRawGyro(rawRoll);

float omega_pitch = convertRawGyro(rawPitch);

float omega_yaw = convertRawGyro(rawYaw);

unsigned long cur_mills = micros();

unsigned long duration = cur_mills - last_mills;

last_mills = cur_mills;

double dt = duration / 1000000.0; // us->s

if (dt > 0.1) return;

// Gyro data

gyro_roll += omega_roll * dt; // (ms->s) omega x time = degree

gyro_pitch += omega_pitch * dt;

gyro_yaw += omega_yaw * dt;

// Complementary filter data

comp_roll = 0.93 * (comp_roll + omega_roll * dt) + 0.07 * accl_roll;

comp_pitch = 0.93 * (comp_pitch + omega_pitch * dt) + 0.07 * accl_pitch;

// Kalman filter data

float kalm_roll = kalmanRoll.getAngle(accl_roll, omega_roll, dt);

float kalm_pitch = kalmanPitch.getAngle(accl_pitch, omega_pitch, dt);

// Madgwick filter data

madgwick.updateIMU2(omega_roll, omega_pitch, omega_yaw, accX, accY, accZ, dt);

// madgwick.updateIMU(omega_roll, omega_pitch, omega_yaw, accX, accY, accZ);

float madw_roll = madgwick.getRoll();

float madw_pitch = madgwick.getPitch();

float madw_yaw = madgwick.getYaw();

#ifdef PRINT_PROCESSING

static int n = 0;

if (n != 50) {

++n; return;

}

n = 0;

Serial.print(accl_roll);

Serial.print(",");

Serial.print(accl_pitch);

Serial.print(",");

Serial.print(madw_yaw);

Serial.print(",");

Serial.print(gyro_roll);

Serial.print(",");

Serial.print(gyro_pitch);

Serial.print(",");

Serial.print(madw_yaw);

Serial.print(",");

Serial.print(comp_roll);

Serial.print(",");

Serial.print(comp_pitch);

Serial.print(",");

Serial.print(madw_yaw);

Serial.print(",");

Serial.print(kalm_roll);

Serial.print(",");

Serial.print(kalm_pitch);

Serial.print(",");

Serial.print(madw_yaw);

Serial.print(",");

Serial.print(madw_roll);

Serial.print(",");

Serial.print(madw_pitch);

Serial.print(",");

Serial.print(madw_yaw);

Serial.print(",");

#endif

Serial.println();

}

void setup() {

Serial.begin(115200);

BMI160.begin(BMI160GenClass::I2C_MODE);

madgwick.begin(SENSE_RATE);

BMI160.setGyroRate(SENSE_RATE);

BMI160.setAccelerometerRate(SENSE_RATE);

BMI160.setGyroRange(GYRO_RANGE);

BMI160.setAccelerometerRange(ACCL_RANGE);

BMI160.autoCalibrateGyroOffset();

BMI160.autoCalibrateAccelerometerOffset(X_AXIS, 0);

BMI160.autoCalibrateAccelerometerOffset(Y_AXIS, 0);

BMI160.autoCalibrateAccelerometerOffset(Z_AXIS, 1);

delay(100);

/* Set kalman and gyro starting angle */

int rawXAcc, rawYAcc, rawZAcc;

BMI160.readAccelerometer(rawXAcc, rawYAcc, rawZAcc);

float accX = convertRawAccel(rawXAcc);

float accY = convertRawAccel(rawYAcc);

float accZ = convertRawAccel(rawZAcc);

float roll = rad_to_deg(atan(accY / accZ));

float pitch = rad_to_deg(atan(-accX / sqrt(accY * accY + accZ * accZ)));

// Set starting angle

kalmanRoll.setAngle(roll);

kalmanPitch.setAngle(pitch);

gyro_roll = comp_roll = roll;

gyro_pitch = gyro_pitch = pitch;

}

void loop() {

print_roll_pitch();

}