Long time lurker, first time poster

Basic explanation about what I am trying to do, receive CANBUS information from my aftermarket ECU (Haltech 750) in my drift car and display certain data on a 2.4” screen

Will copy/paste what I posted on a niche Facebook Group below, any advice/criticism is welcome!

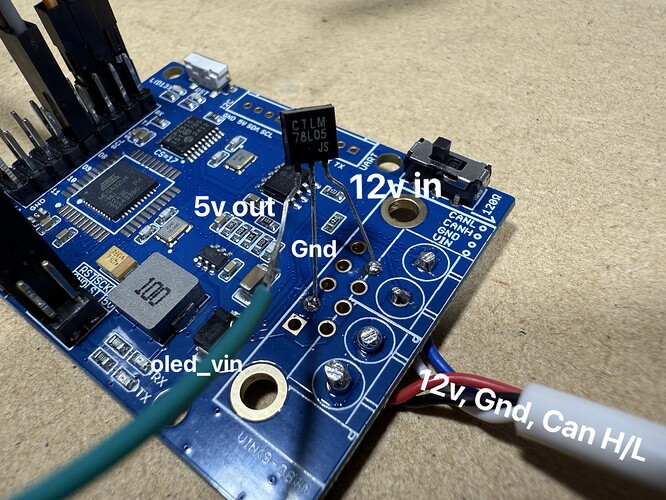

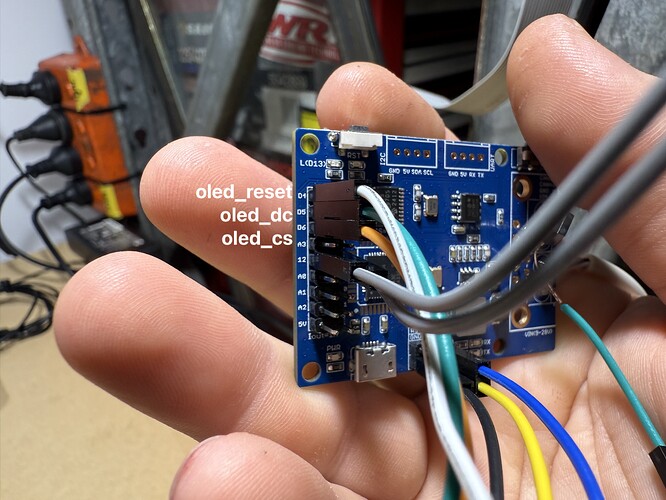

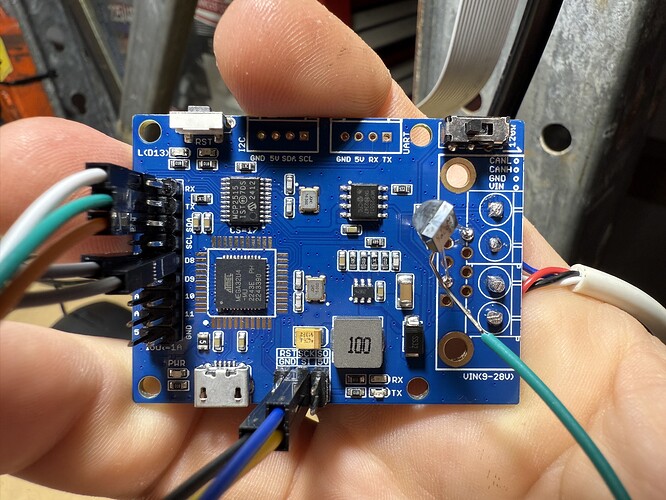

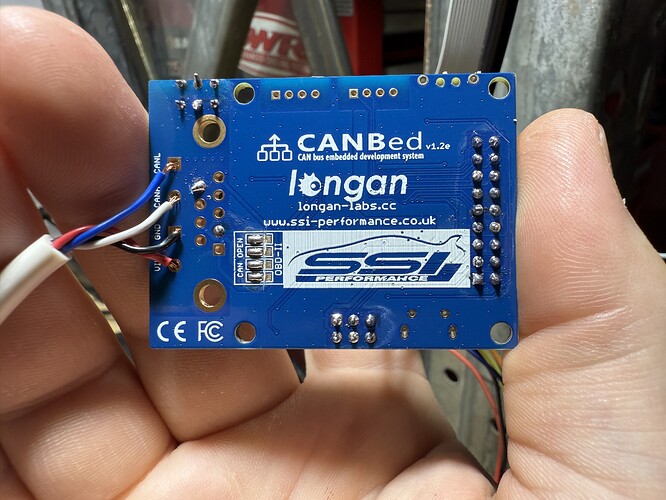

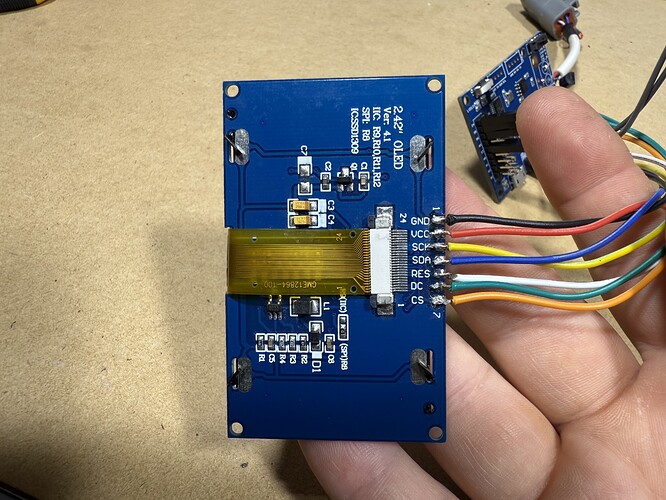

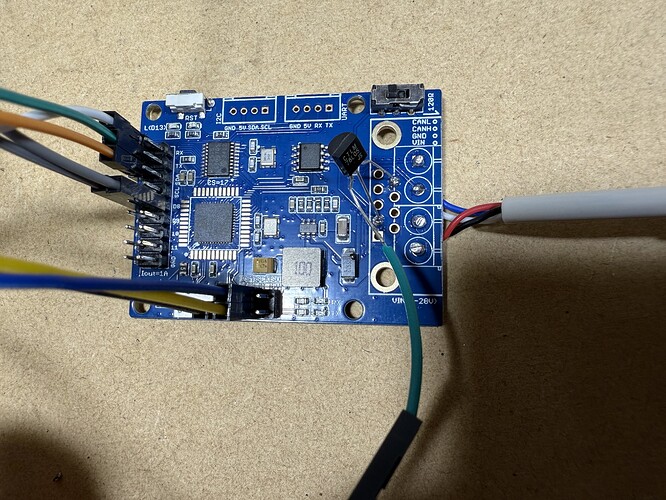

‘Overview: Haltech Elite 750, WB1 controller, CAN Cable plugged into WB1 controller, SSD1306 Screen running with Hardware SPI, CANBED V1 board

Ditched the second hand Hobbytronics board I was using and ended up getting a CANBED V1 board and used a random 2.4” screen I had laying around to get it working

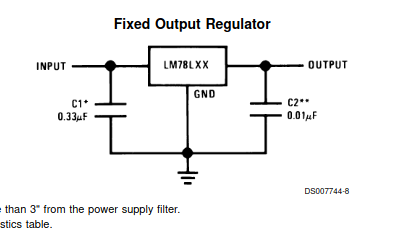

Used a bit of the ELITE GAUGE code as a base to adapt for my setup/use, also adopted an L78L05 to give the screen 5v power as the board wasn’t happy supplying the screen 5v from its ICSP header while also receiving CAN stream (no idea why)

Everything was running swell when I just had ignition on, but it all went to shit when I started the car and the CAN positive went from 12v to 13.9v, Voltage regulator died (weird as it should be able to handle up to 35v input voltage) and killed the screen, presumably killed the board and possibly killed my Wideband Controller as it was sending 7v from the Voltage regulator ground down the CAN ground

Can someone explain what/where I went wrong

Arduino/Coding is the most difficult thing I’ve ever taught myself and I thought I could see light at the end of the tunnel until I let the smoke out of the voltage regulator’

Thanks for reading

Attached is a photo of my basic setup

‘Rough idea of my setup. When it was all working, I had the red wire from the screen plugged into the green wire coming from the Vo of the Voltage regulator’