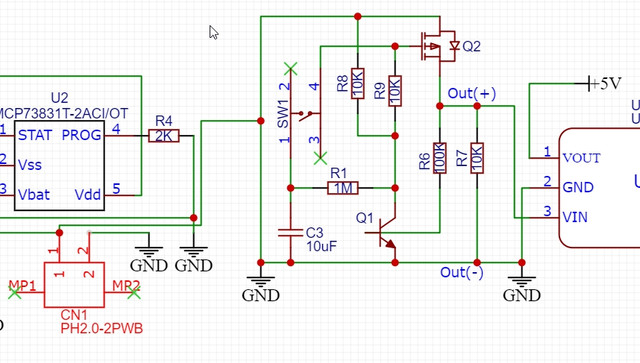

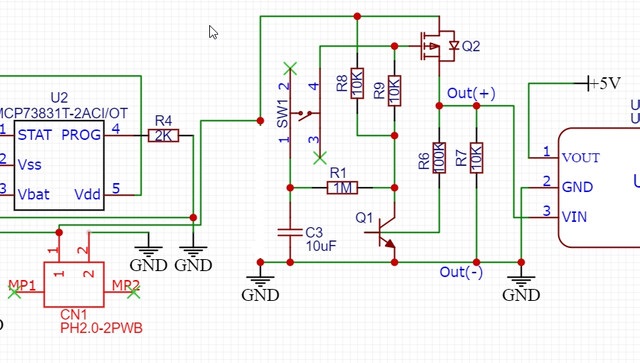

I could really use some help/guidance on a couple of issues I'm having. The first issue is that I'm trying to incorporate a soft latching power switch into my project. I'm trying to use the same circuit as the photo below.

The circuit is from here

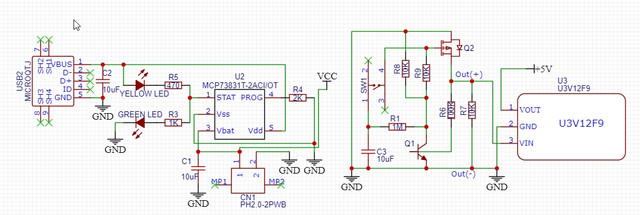

Below is an image of my current schematic. It may be a noob question but I'm completely unsure about how I'm suppose to connect the positive terminal of the JST battery connector to the soft latch circuit. The idea is that the battery would be enough to trigger the circuit and then that would run to the U3V12F9 boost converter which would then go to on to power the rest of the circuit with 5V. I'm not sure if I'm connecting the positive and negative outputs of the circuit to the converter correctly either. ![]()

My other issue is how to choose the correct BJT for Q1. For Q2 I've chosen a P channel MOSFET, the datasheet says that it has gate operator with voltages as low as 1.8V so I believe this should work. I've been researching about BJT's but I don't seem to be getting it. I'm still very new to electronics so there is a lot I don't know that others would probably consider common sense. Can anyone offer a suggestion or at least fill me in on what I should be looking for when selecting a component for Q1? I forgot to mention that the max draw of the system is 1 Amp but its usually much less. Also if there are any other glaring mistakes on my schematic please let me know, any help is greatly appreciated!