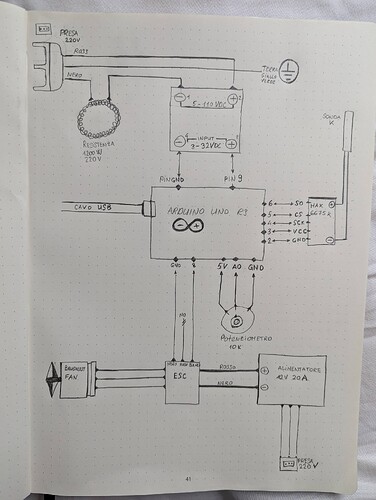

good morning everyone, for a few days I've been trying to create a coffee roaster from a popcorn machine and control it with Artisan Scope. These will be the components:

- PopCorn Machine 1200W - 220V

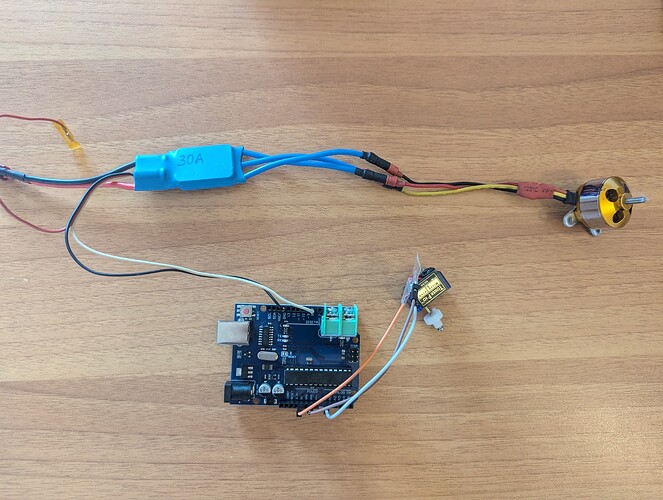

- Arduino Uno R3

- MAX 6675 K

- SSR 40A - 220V

- Brushless ESC - 30A

- Brushless FAN (2200kv - 12V which is used in RC Airplanes)

On the web I found a code that allows me to see the temperature with Artisan and manage the heating resistance with the SSR relay.

Later I added another code to control the fan but only with a 10K potentiometer.

My request is the following, what code do I have to add to also manage the Brushless Fan from Artisan? I opted for a brushless motor because I used to do model airplanes and therefore I have it available and also because it has much more power than the brushed motor.

I attach some photos.

#include <max6675.h>

#include <ModbusRtu.h>

#include <Servo.h>

Servo ESC;

// data array for modbus network sharing

uint16_t au16data[16] = {

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, -1

};

/**

Modbus object declaration

u8id : node id = 0 for master, = 1..247 for slave

u8serno : serial port (use 0 for Serial)

u8txenpin : 0 for RS-232 and USB-FTDI

or any pin number > 1 for RS-485

*/

Modbus slave(1, 0, 0); // this is slave @1 and RS-232 or USB-FTDI

// Pins for thermocouple MAX6675

int thermoDO = 6;

int thermoCS = 5;

int thermoCLK = 4;

MAX6675 thermocouple(thermoCLK, thermoCS, thermoDO);

// declare variable for Arduino pin connected to solid state relay (SSR)

int relay = 9;

// declare variables for Arduino pins connected to fan controller (L293N)

int fan = 10; // ENA of L239N

int in1 = 11; // IN1 of L239N

int in2 = 12; // IN1 of L239N

// declare variables for Arduino pins to power MAX6675:

int vccPin = 3; // 5v power of MAX6675

int gndPin = 2; // gnd of MAX6675

// slew rate limitations for fan control

#define SLEW_STEP 10 // increase in steps of 10% for smooth transition

int target = 0;

int current = 0;

int potValue; // value from the analog pin

void slew_fan() { // limit fan speed increases

target = ((au16data[5] / 100.0) * 255);

if ( target < current ) { // ramping down, so check rate

uint8_t delta = current - target;

if ( delta > SLEW_STEP ) // limit the step size

delta = SLEW_STEP;

analogWrite(fan, (current - delta ));

current = current - delta;

}

else if ( target > current ) { // ramping up, so check rate

uint8_t delta = target - current;

if ( delta > SLEW_STEP ) // limit the step size

delta = SLEW_STEP;

//write current fan value for air control

analogWrite(fan, (current + delta ));

current = current + delta;

}

}

void setup() {

slave.begin( 19200); // 19200 baud, 8-bits, even, 1-bit stop

// use Arduino pins

ESC.attach(8,1000,2000);

pinMode(relay, OUTPUT);

pinMode(fan, OUTPUT);

//fan direction can be reversed by interchanging values for in1 and in2

pinMode(in1, OUTPUT); digitalWrite(in1, HIGH);

pinMode(in2, OUTPUT); digitalWrite(in2, LOW);

pinMode(vccPin, OUTPUT); digitalWrite(vccPin, HIGH);

pinMode(gndPin, OUTPUT); digitalWrite(gndPin, LOW);

delay(500);

}

void loop() {

//write current thermocouple value

au16data[2] = ((uint16_t) thermocouple.readCelsius() * 100);

//write current fan value for air control

// analogWrite(fan, (au16data[5] / 100.0) * 255);

slew_fan();

potValue = analogRead(A0); // reads the value of the potentiometer (value between 0 and 1023)

potValue = map(potValue, 0, 1023, 0, 180); // scale it to use it with the servo library (value between 0 and 180)

ESC.write(potValue); // Send the signal to the ESC

//poll modbus registers

slave.poll( au16data, 16 );

// heater control:

digitalWrite(relay, HIGH);

delay(au16data[4] * 10);

digitalWrite(relay, LOW);

delay((100 - au16data[4]) * 10 - 1);

}