HazardsMind:

modifying the inexpensive rc toys is pretty much a no go.

Why is that? That's what I did to my RC truck and as far as the speed, you can control that easily with PWM.

I'm kinda curious on this, too - especially since some people have managed to control their RC cars by emulating the output from the receiver (the pulse code provided by the transmitter) - on RX2/TX2 and variant chipset cars:

http://forum.arduino.cc/index.php/topic,86883.0.html

The only thing I can think of that would be objectionable is that on some cars, it can be difficult to find proper solder points, and that some use lower voltages and whatnot for the control of the on-board h-bridge drivers. As such, it can be easy to blow them rendering them useless. There's also the fact that you don't have proportional control of the steering in most cases, either (this could be rectified by substituting a real RC servo for the existing steering mechanism, though.

Worst case (sometimes the best option, sometimes the only option), you strip out all of the control electronics, and then use some other driver circuitry that is easier to control with your microcontroller of choice to control the actuator(s) and drive motor(s).

HazardsMind:

But if you want to add things to the RCs, then yea, its a pain in the butt. But if you just want to mod the rc to work with an Arduino, just for fun or to say that you did it, then it is very easy.

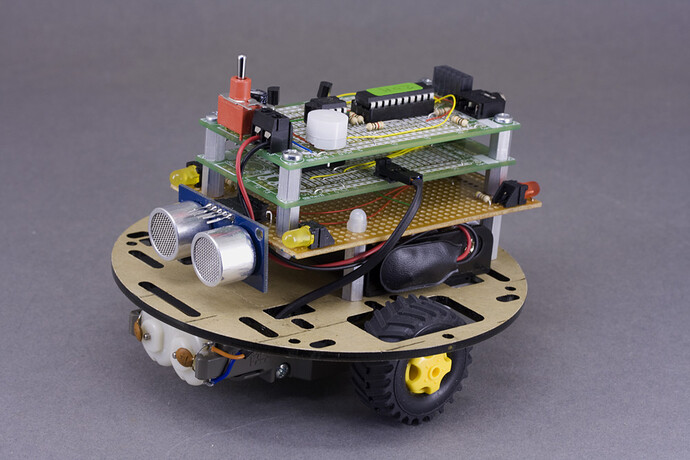

Most toy RC vehicles, once stripped of the outer shell, can be easily modified to add a "deck plate" onto which other things can be attached (sensors and such). This deck can be constructed of plastic, plywood, or other materials as needed (foamcore or coroplast can work well - even cardboard can work).

HazardsMind:

I personally prefer to make my robots by hand, from Legos or an Erector set, just so if there is something I want to change or add to it, I can. This also allows me to be creative with the designs too.

The only problem with Erector/Mecanno is typically the weight issue, being steel, but as long as that is kept in mind, the chassis and other systems can be engineered to work around it. Lego, on the other hand, tends to be very expensive for what you get, but it does lend itself to being a great prototyping platform - provided you are willing to take apart your creations.

HazardsMind:

Right now I am building a hollow wheel motorcycle with Legos. I am finished with the design, and now I just need to figure out the placement of the electronics. I do still need to work out how it will balance itself.

That's a pretty neat chassis - and one that puts lie to my earlier comments; in this case, you couldn't easily make that chassis out of anything else (unless you had access to a good machine shop - or a laser cutter and/or 3D printer) - and you would likely want to make the chassis a "permanent" one. I guess in this particular case, Lego wins!

As far as balancing is concerned, you might want to add the ability for the bike to "put a foot down" - maybe some kind of "training wheels" that can be let down as the bike slows, then raised up (like aircraft landing gear) as the bike speeds up and the gyroscopic action of the wheels take over to keep it balanced. You'll probably also want to add some kind of accelerometer or similar sensor so that your robot can determine how far it is leaning as it turns, among other potential issues related with keeping the bike upright...