Thank you for your comment.

I did not know about this quite cheap encoder, that you links to. You are right, that I want to be able to use low speed for heavier fabrics and heavier thread (Tex 135). In order to sew leather you got such requirements. But you need that for strong seems in vinyl or dense webbing as well.

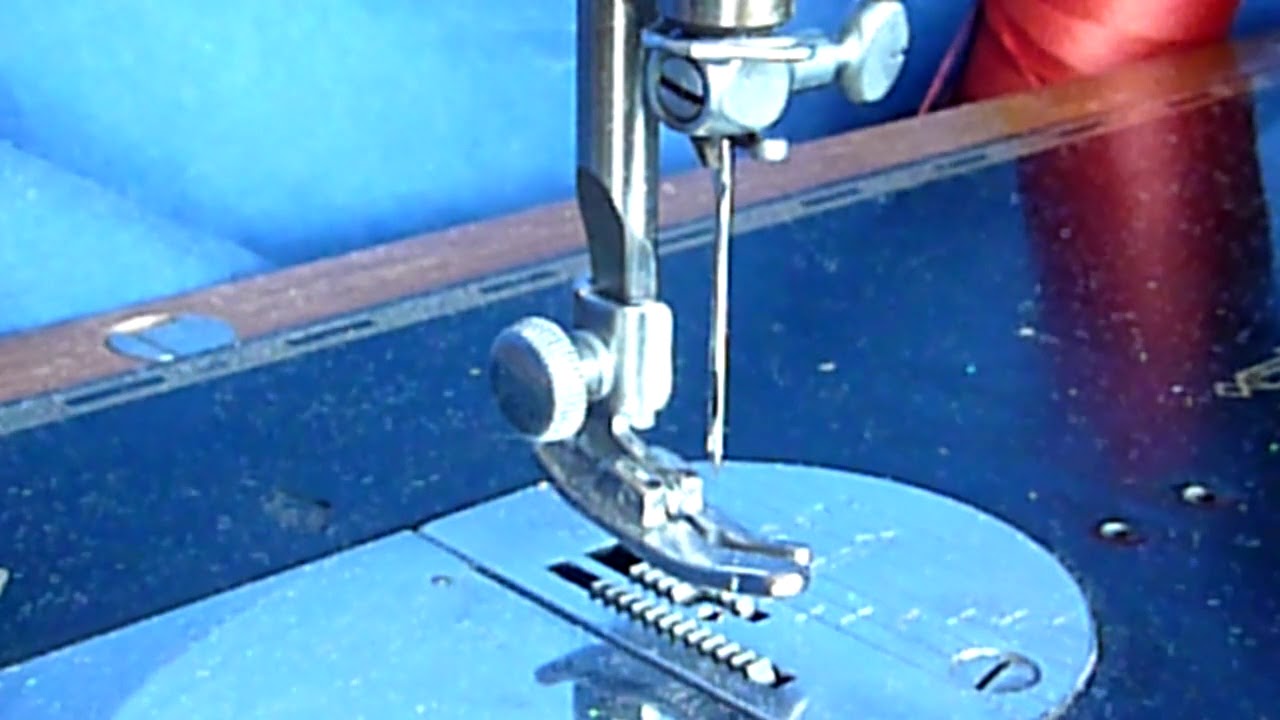

In this video (you see linke above as well), you see five tests, you can do to make sure, that you got good speed control. The machine use a speed reducer, an universal motor and electronics with a small DC-motor for speed feed-back. It is conventional electronics and no Arduino:

This video demonstrate a speed range on sewing machine of 8 to 540 stitches/minute.

In my experience, you need the motor to provide a torque on the main shaft of the sewing machine of at least 3 Nm, and with the common universal motors for sewing machines, you can achieve that with a gear ratio between motor and machine of 1:20. You find the torque-speed characteristics of some of the common sewing machine universal motors here:

https://youtu.be/VLU_s1RGasA&t=216

When you sew at low speed, it will only be a small part of the time, that a high torque is needed. The universal motors and the DC-motors I look for would overheat, if the high torque should be provided continuously, but it would not happen. Some way of measuring current and estimate the motor winding temperature could add some protection of the motor against over temperature. I have got one of the 250 W Chinese universal motors, and it heats up very fast, when it provides torque near its maximum.

Furthermore, I should like the machine to sew fast like 1800 stitches/minute. A few popular vintage household sewing machines are able to handle that, such as Pfaff 130 or Pfaff 230. I think some of the smaller cheap DC-motors designed for use in powerful battery tools might be able to handle this. The universal motors for sewing machines are not able to do that range of speed and torque.

I noticed in your link, that DC voltage was used to control the universal motor. It do demonstrate, that it is possible, but it do also include some risks to use this high DC voltage on them. If for some reason the belt to sewing machine snaps, the motor can increase speed that high, that centrifugal forces will destroy the motor. AC voltage limits the possible speed on these motors.

The other problem is arcing at the commutator. At high current and torque, arcing can cause short circuit. AC current ensures clearing of the commutator arcing at zero crossings in the current.