I thought I'd take a moment to share my current project with the arduino world because I have some downtime. I still just can't believe I got 4 bad 9g servos all in nice packaging from amazon.

But I've been developing this thing for a while now. I think I finally have a design that looks like a real product (but made by someone in his garage).

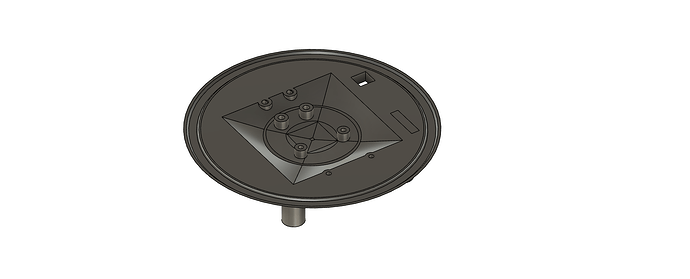

The idea is that I pull a vacuum to draw water out of the plant material, then open the lid to blow it off. Keep doing that until it reaches a certain moisture level. Mold is taken care of with an ozone generator. The moisture content is estimated with two humidity sensors and also a load cell measures the amount of water lost.

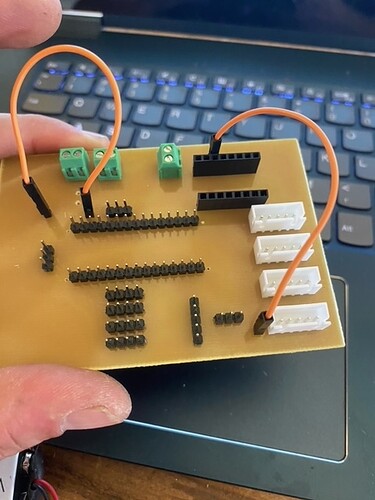

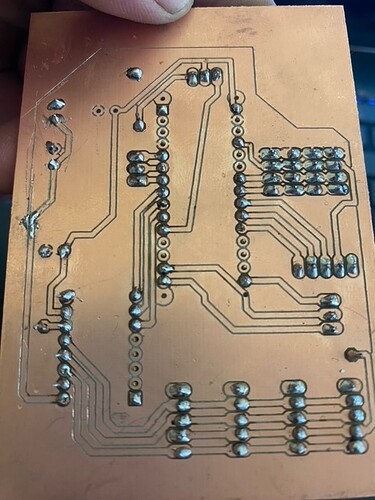

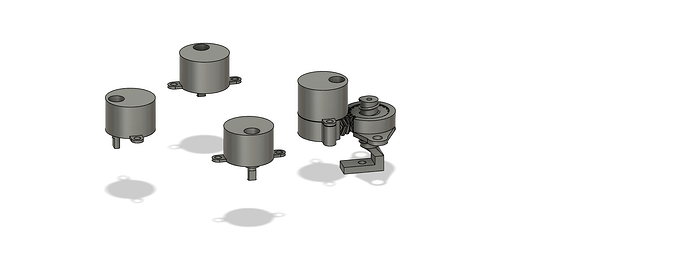

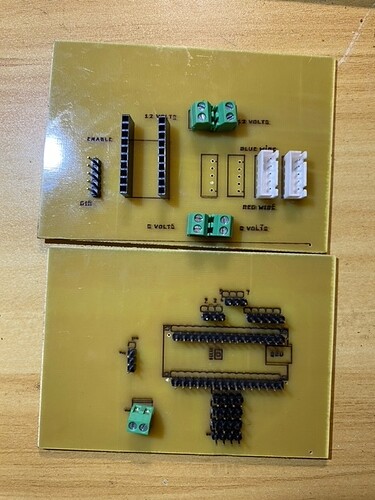

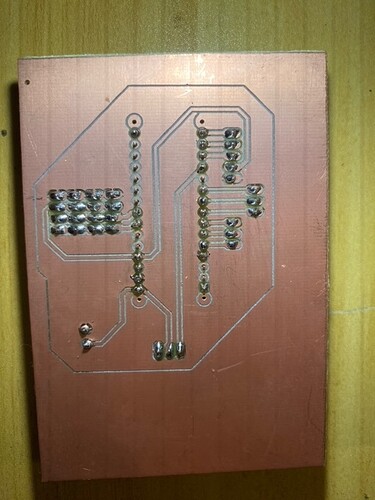

Some details: the lid opens and closes with 4 28byj stepper motors. The baine marie is about 3.5 quarts and the whole frame fits it like a glove. I'm using two humidity sensors that cost about 15$ a piece but still their always 10% off from each other. The load cell is 2kg and has a good resolution at the gram level (crosses fingers). I'm using my own pcb's for right now, made on a 3018 cnc.

Where i'm at right now and where I've been for the last week: I'm spending my days doing things on the computer and my nights putting things together in the workshop. This is my first time going at something of this scale, and its fought me every step of the way. Just about nothing has not been poured over because I can't figure out what is going on. My worst fear is that its hocus pocus and I give up on it (and burn it at the stake). But the whole project burned down just last night, I figured out after tearing everything apart that I had the red wire and the black wire hooked up on the relays! But you know it still worked mostly, except the i2c line kept getting hung up talking to the arduino reading the load cell. But it all just seemed really unstable. Oh well, then I get a bunch of 9g servos and none of them work. I checked everything! But amazon is famous for having broken junk. I have some coming tomorrow.

If anyone is curious why I'm going through all the trouble of preserving flowers, I think of it as an art. If you can take something living and just keep halving what it has, so that it hardly notices, until its to the very edge of death and you just tip it over, thats something like the art that the gods are involved in. Plus I have no way to make any real amount of money unless its through this thing. I'm hoping to develop it into a full fledge device with a TFT display instead of the rotary encoder and LCD setup.