I am not an electrical engineer, and I don't know much about electronics. I'm an IT guy and typically write programs in C# and manage SQL databases and such, but I have been tasked with a project that requires me to assemble some electronic components.

The Facilities Maintenance Director of our company has asked me to start logging differential pressure readings from the 12 filter houses throughout the plant into a database. There are analog needle-type gauges on each of the filter houses, and machine operators are supposed to occasionally look at these gauges, and then react if the differential pressure is either too high or too low. The operators NEVER look at the gauges, and it's a problem when filters get clogged or a hole gets ripped in them.

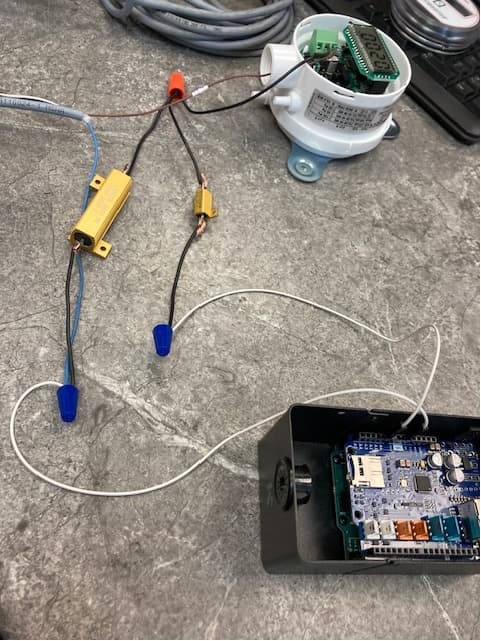

I have an Arduino Uno Rev3 with an Ethernet Shield. I also have a Dwyer MS-621-LCD, which outputs a 4-20mA signal of its differential pressure reading.

I have been reading numerous posts on this forum about how to connect the differential pressure sensor to the analog input on the Arduino Uno Rev3.

There is a 24V power supply for the Dwyer differential pressure sensor, and the Uno is powered separately with POE from its Ethernet connection.

I have gathered that I need a 250 Ohm resistor that will convert the 4-20mA signal into a 1-5V signal.

There also needs to be a 10,000 Ohm resistor that will protect the analog input on the Uno from being fried.

Here is my rudimentary wiring diagram.

My question is regarding the different specifications for the resistors.

For the 250 Ohm resistor and the 10,000 Ohm resistor, do I go with an 1/8W, 1/4W, 1/2W resistor?

How important is the tolerance? I've seen 0.1% or 5% tolerance on resistors. I'd like the readings to be as accurate as possible, but I don't want to spend more on 0.1% tolerance if it's not actually going to have that tolerance. Are the advertised tolerances telling the truth? I suppose there is no way to tell other than to just know what the trusted name brands are.

I'm hoping that these will be a couple of easy questions for the seasoned experts on this forum, and then I will be able to order a couple of the correct resistors with confidence to assemble a prototype to start gathering differential pressure readings.

Thanks.