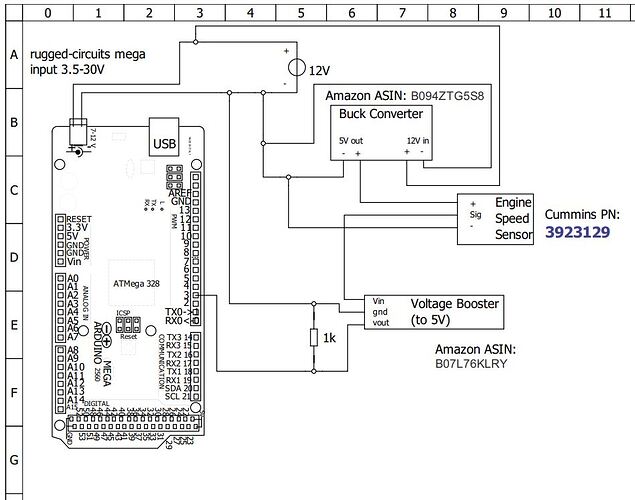

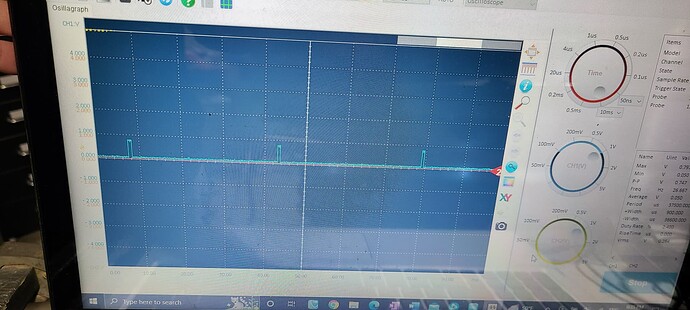

Thank you all for the input. Please keep in mind that everything about this circuit works when I test triggering it with my bench top power supply. It only stops working when I try to trigger off the speed sensor itself and the reason why is the current from the speed sensor is too low to drive the voltage booster I'm using, so the voltage never gets boosted high enough for the arduino to read it. When I'm using the benchtop supply to feed 0.8V to the voltage booster I can confirm that it triggers as expected above 50mA, and doesn't work under 50 mA. I verified with an oscilloscope that the speed sensor outputs square 0.8V pulses. I can include some code and wiring if you'd like, but it's kind of complicated and would take me a bit to draw up.

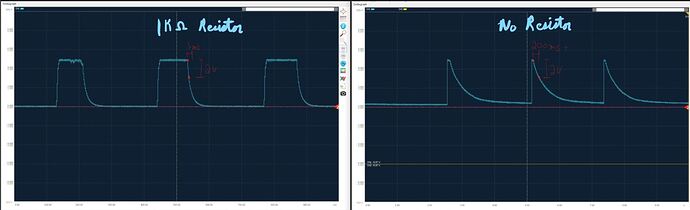

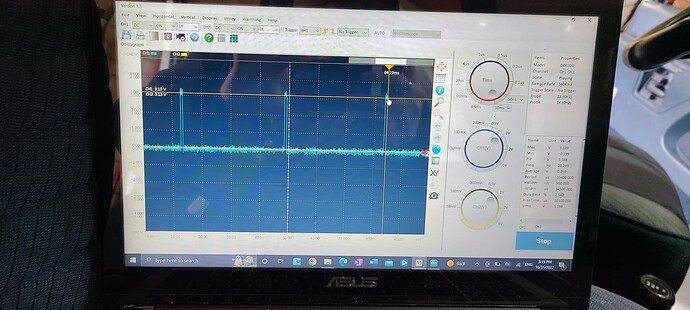

I don't understand why. The pin on the arduino is normally low, 0V WRT ground, correct? Why would adding a resistor between this pin and ground load the internals? Perhaps the terms I'm using are incorrect. I added a 1k resistor between ground, and the node that includes the arduino input pin and the 5V pulsed signal. The reason why is because in my bench testing I needed the voltage boosted signal to return to 0V quicker, otherwise it wouldn't ever fall below 3V and would effectively stay high all the time. See picture (note the time scales are different between the two graphs, first one falls from 5V to 3V in 3 ms, the second in 200ms+).

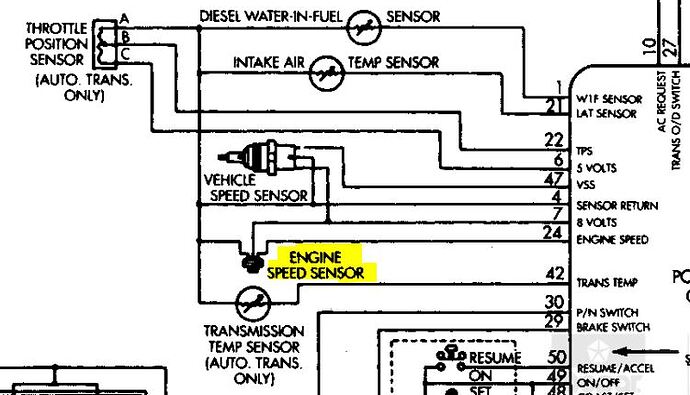

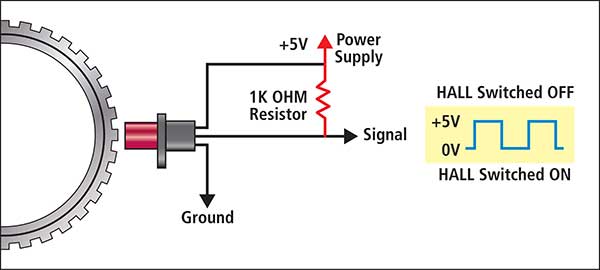

Unfortunately I haven't found an answer to this. What it IS outputting is 0.8V pulsed square wave as verified with an oscilloscope. There is no ECU (engine is mechanical and doesn't need one to run and was swapped into a different vehicle). I am feeding it 5V either with the buck convertor or with my benchtop supply depending how I'm testing it. The three wires are ground, +5V, and signal (0.8V pulsed square). You may be correct about what type of sensor it is, but I was pretty sure the manual called it a hall effect. It has a permanent magnet in it and some circuitry to make the output digital. It runs off DC. Other than that I'm not certain what it is. Perhaps it IS wired wrong but it appears to be outputting a pretty clean signal.

Sensor

See picture for a wiring diagram from the manual. It does look like the manual specifies 8V not 5V feeding the sensor, however I tested this before and there didn't appear to be a big difference (.1V or so on the output) if I feed it 8V or 5V. I will test this again to be sure, I wanted to stick to 5V since other sensors use 5V.

Hmm I haven't heard of this. is this a problem even when there is a common ground? How should I fix this, or know it's an issue? What is the recommended way to power something if it asks for more power than the arduino can supply?

This is very interesting. I tried adding a pullup resistor and there was no change. However I'm going to pull it off the car and do some testing, see if the wiring of the sensor is the issue.

Looks like I have some more testing to do, however I may be out of time this weekend. I'll try it again on 8V, and try to research the pullup resistor on the sensor some more. Thank you all again.