MrAl:

Hello,

I was thinking of getting a Due, but would like to know the current status of the IDE with the Due.

Does it really work properly without any major issues?

I dont want to shell out the bucks unless i can be sure it will work with the IDE.

Also, how much is involved with downloading new files for use in the IDE, or does the new IDE include everything needed to program and operate the Due board?

Note this is the Arm 32bit Due board i am referring to.

Thanks much

MrAl:

Hello,

I was thinking of getting a Due, but would like to know the current status of the IDE with the Due.

Does it really work properly without any major issues?

I dont want to shell out the bucks unless i can be sure it will work with the IDE.

Also, how much is involved with downloading new files for use in the IDE, or does the new IDE include everything needed to program and operate the Due board?

Note this is the Arm 32bit Due board i am referring to.

Thanks much

I have switched to SAM3X8E / ARM , I prefer to use that name since Due is IMHO just poor marketing choice implying some technology continuity between basic Uno, which there is very little of. I use SAM mainly to get away from memory limits of Uno since I prefer to debug my code heavily by using Serial prints ( I know about F macro ) .

As far as Arduino IDE and SAM it has same version issues as Uno.

The main disadvantage of SAM is lack of "industrial strength" users.

You do not need SAM's horsepower to blink LED, simple as that.

So far I do not see the processor speed as big advantage.

The hardware features of SAM3X8E are a big plus, even when most of them are not accessible by Due.

I am sure somewhere exists a full blown board with access to ALL pins!

I am planning to utilize "native USB " port, but current "off the shelf" software ( IDE examples ) is a very poor introduction / incentive to using native USB port.

As far as SAM3X8E / ARM as a teaching aid it really depends on (your) goals.

If (your) teaching motto is "Arduino is a toy" ( not uncommon opinion of a few , not just mine , if that is of any consequence ) it would be "abuse of technology " sort off.

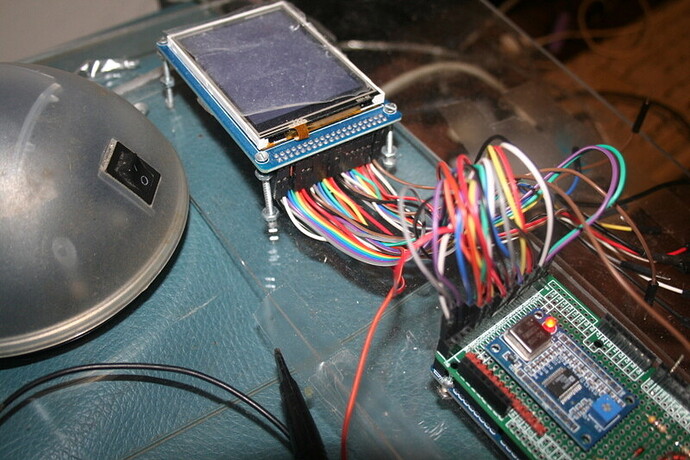

![]()