For my ESP32-based ramp/soak temperature controller project, I write out multiple firing schedules on an excel spreadsheet, and then save each of these schedule's to a separate comma delimited text file (.txt).

The text file is stored on an SD card. The ESP32 will then read this file into a temporary char buffer, and then the data is parsed into variables.

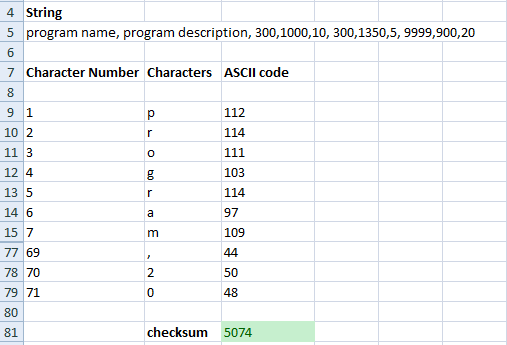

Currently, each text file is in human-readable ascii, is contained within start/end markers, and looks something like this:

“<program name, program description, 300,1000,10, 300,1350,5, 9999,900,20>”

The length of these text files could be something like 80 characters minimum to 400 characters max (ballpark).

I am confident in the basic techniques to get all this data parsed by the esp32, and how I could split a large program into multiple packets to save on SRAM.

I am now interested in how I can add a fairly robust error checking protocol to this data, and how to use one in both MS Excel and the ESP32, which will prevent any erroneous transmissions from the SD card to the ESP32, through either noise, fault in the SD card, etc.

I have some basic understanding of how CRC’s and checksums work, where you calculate a number and add it to the end of a transmission, and then you recalculate the number on the receiver side and check if both numbers match, but I’m not too sure which type of error checking protocol would be sufficient for this use case, and how to use one in both excel and the ESP32.

I’d appreciate any guidance to get started on this.