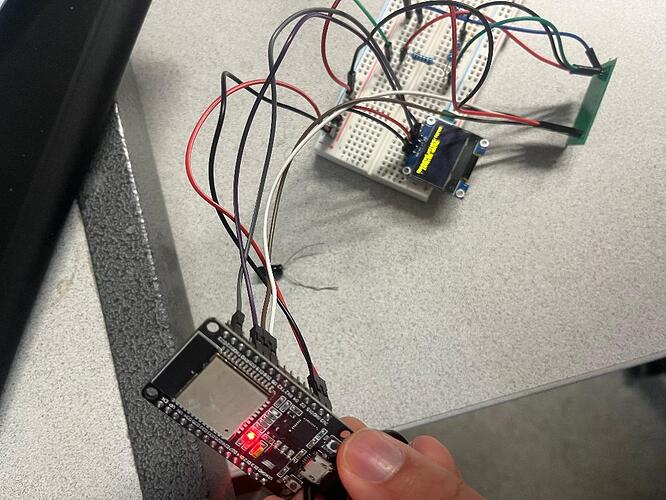

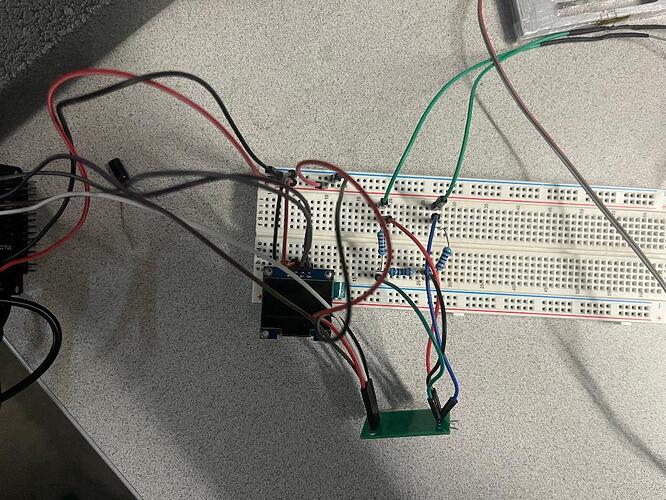

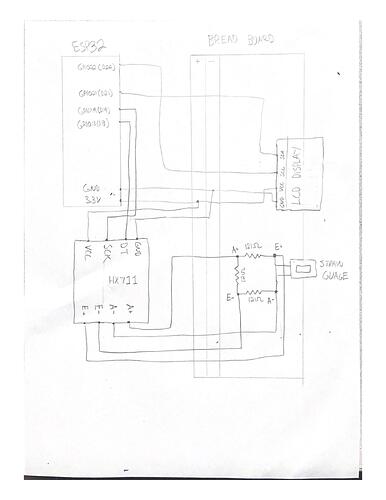

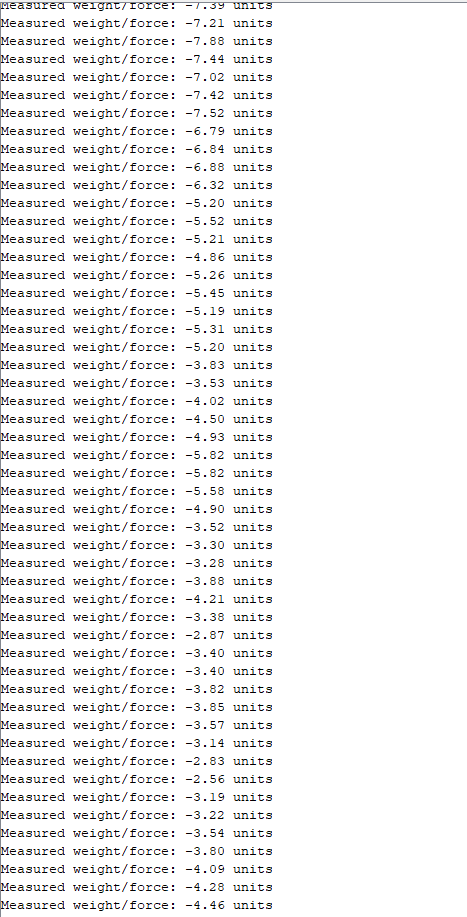

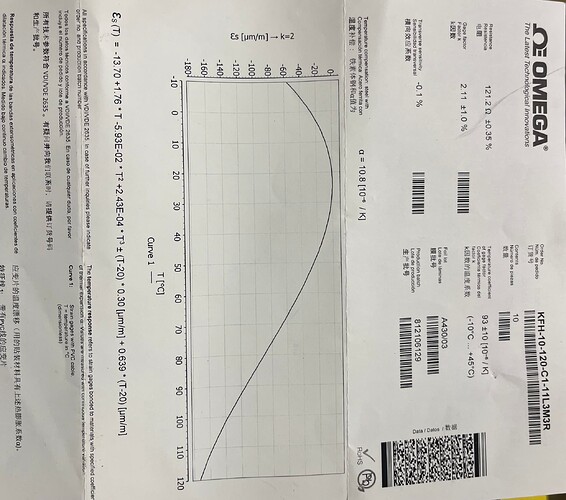

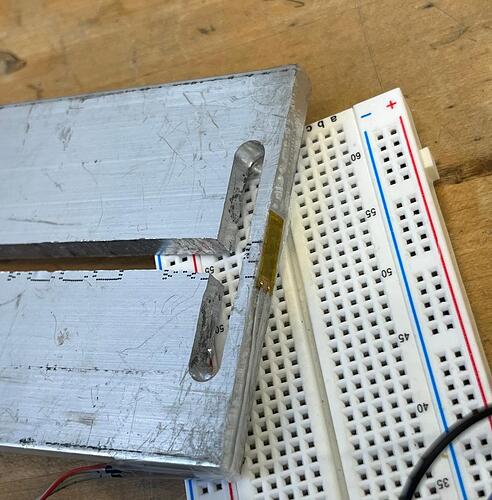

I am looking at making a strain gauge with an ESP 32, Wheaton stone bridge made up off 121 ohm resistors, a 121 ohm strain gauge and HX711 amplifier. When I upload my code I get sporadic values or values the will steadily increase or decrease. I have included my code and some wiring diagrams:

#include "HX711.h"

#include <Wire.h>

#include <Adafruit_GFX.h>

#include <Adafruit_SSD1306.h>

// HX711 circuit wiring

const int LOADCELL_DOUT_PIN = 18; // Data pin

const int LOADCELL_SCK_PIN = 19; // Clock pin

HX711 scale;

// OLED display configuration

#define SCREEN_WIDTH 128 // OLED display width, in pixels

#define SCREEN_HEIGHT 64 // OLED display height, in pixels

#define OLED_RESET -1

#define SCREEN_ADDRESS 0x3C // I2C address of the OLED display

Adafruit_SSD1306 display(SCREEN_WIDTH, SCREEN_HEIGHT, &Wire, OLED_RESET);

void setup() {

// Start serial communication for debugging

Serial.begin(9600);

scale.begin(LOADCELL_DOUT_PIN, LOADCELL_SCK_PIN);

// Initialize OLED display

if (!display.begin(SSD1306_SWITCHCAPVCC, SCREEN_ADDRESS)) {

Serial.println(F("SSD1306 allocation failed"));

for (;;);

}

display.display(); // Clear the buffer

delay(2000); // Pause for 2 seconds

// Tare the scale to zero it out

Serial.println("Taring the scale. Please ensure no weight is applied.");

delay(2000); // Wait for stabilization

scale.tare();

Serial.println("Taring complete.");

// Set scale calibration factor

// Replace with the calibration factor determined experimentally

scale.set_scale(2280.0); // Example calibration factor

}

void loop() {

if (scale.is_ready()) {

// Read the weight or force

float weight = scale.get_units(3); // Average of 3 readings

// Display on OLED

display.clearDisplay();

display.setTextSize(1);

display.setTextColor(SSD1306_WHITE);

display.setCursor(0, 0);

display.print("Measured weight/force: ");

display.print(weight);

display.println(" units"); // Replace "units" with "grams" or "kg" after calibration

display.display(); // Show the updated display

// Display on Serial Monitor

Serial.print("Measured weight/force: ");

Serial.print(weight);

Serial.println(" units"); // Replace "units" with "grams" or "kg" after calibration

} else {

Serial.println("HX711 not found. Check connections.");

}

delay(500); // Delay for readability

}