Last year, thanks to the good people on this forum, I designed and successfully built my first PCB board to control a PWM radiator fan for a Mercedes Benz. See:

The controller uses an Arduino Nano 3.3BLE. At the time I did not know what BLE stood for and wasn’t using any of those functions. But I have since learned that I could use the BLE functions to report the three variables Radiator temperature, AC condenser temperature, and under hood temperature. The previous version had the capability of connecting 3 LED’s to blink out a binary sequence of codes to know these temperatures. Consequently the LEDs will now be inserted onto the board and just indicate the status of the three thermisters are in range as in not shorted or open.

While the current setup can do this without any physical modifications, there were other lessons learned that I would like to implement at this time. As explained below.

Connectors

The weakest link I have observed so far is the connectors I chose to do the original job. These turned out to be not adequate and failed immediately on connection. I actually found selecting connectors to be one of the most difficult jobs for the uninitiated like myself. Because I wanted this to look like a factory like installation, I wanted connectors instead of screw terminals.

The first set of connectors I chose was the TE 5-102617-6 and TE 102448-6 pair. Several issues I had with this connector set

- Connectors are not keyed. I could easily mate them upside down

- Connectors do not latch together

- Connectors are made for 20ga max wire. I was using 6 20ga and 1 18ga

- The area where the wires crimp on the TE 102448-6 connector is not supported. This became the Achilles heal and the reason I had to replace it immediately. Trying to manipulate this connector in place under the dash of the car, caused these pins to fold and break right at the point where the pin is not supported. I had come to the conclusion that these connectors were made for very light ribbon cables in computers etc. They worked on the bench But?

TE 5-102617-6 and TE 102448-6

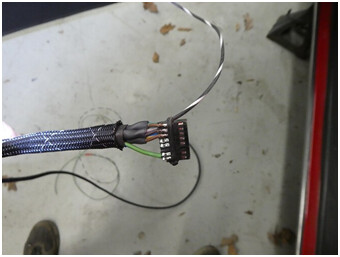

Below is the TE 102448-6 shown installed on the Automotive wire harness.

TE 102448-6 Installed

After the failure I was able to find another set of connectors that would address problems 1, 2 and 4. Problem #3 was dealt with as it was for the first set of connectors by removing a few strands of the 18ga wire so it could be crimped on to a 20ga pin. It all works reasonably well and is currently installed in the car now, however I am aware of its flimsiness and the latches are weak and it has been known to come loose.

TE 102387-3 and TE 104130-3

So now, since I don’t need 16 pins for LED outputs, I was able to find an Automotive quality connectors of 8 pins for the signal wires and 3 pins for power. These connectors are:

TE 1717412-2, TE 178289-4,TE 1-178293-2, TE 1-178288-3

Thermister Capacitors

During the development of the original board, there was a lot of critique on the way the filtering capacitors needed to be connected for the thermisters. Discussions ranged for would not work at all to it will work but it’s not the preferred solution, etc. So I did some research and found a solution proposed by a thermister manufacture, Northstar Sensors. The manufacture also proposed turning on the thermisters only when you need to take a reading. I consider the thermister manufacture to be the “horse’s mouth” if you will, so I will go with that. The article is presented here:

The circuit schematic for the current and proposed PCB is presented below. These show the difference in capacitor arrangement. The new schematic also shows a voltage sensing scheme. That will be used to tell if the engine is running or not.

The current circuit schematic as it stands today

The proposed circuit

Engine Running Sensing

It is desirable to only run the fan in this car while the engine is running or maybe for 30 seconds after shutting it off. Keep in mind this fan can draw up to 50 amps. So if you want to park the car and turn on the radio with the key on, running the fan for longer periods of time is not a good idea. The circuit can be activated in 2 ways.

- Sense the key on voltage and determine if it is > 13.5V meaning key is on and engine is on. < 13.5V means key is on engine is off.

- Sense the field in the alternator. That is kind of a strange circuit and for this car, there is an electronic indicator that I’m not sure I can implement it without jacking with the vehicles warning light system.

Input Over Voltage Protection

During the development of the old PCB input voltage regulators were suggested. I did try to implement one but found my soldering skills to be lacking for the model I tried. In any case I have been running flawlessly without it just by feeding straight ignition voltage to the Arduino Nano 33BLE. However I would like to provide some voltage spike protection to the circuit. You will see these as the 2 SLD18-018 Transorbs.

Built in LEDs

As stated before the original design had circuitry for three external LEDs which would blink out binary codes so that the temperature of each of the three sensors could be determines. It was required for these to be external because the controller mounts under the dashboard of the car. With the use of BLE communication this is no longer needed. But the three LED’s will remain fixed in the box poking through the cover and be used as a thermister circuit test when the system boots up.

Using BLE

So now that I know what BLE stands for, I fully intend to implement it so I can read the temperatures and fan speed as I’m driving. To date I can use the Light Blue BLE app to read the data but it only reads one piece of data at a time and needs me to flip pages to read each value. Not a good thing to do while driving. But with the help of the MIT App Inventor community, I’ve put together an app that reads the temperatures and fan speeds and presents it to my cell phone all on one page. So far I have only sent it dummy values to get a handle on how it works but it’s coming along.

So where am I now?

To date I have ordered all the pieces to breadboard it and try a few things out. I have just moved house so finding everything is going to be a challenge. At this point any critiques or advice is welcome.