Good afternoon everyone.

I am developing a line follower robot with a PID algorythm. I stopped working on the robot in early December, and resumed the project last week. The code I used made the robot complete a circle, however, it was quite slow. Furthermore, when I was testing it out today, I couldn't get it to do the makeshift course I made at home, and the actual course from the robtics club. It would either only turn on one wheel, or not move entirely. The code I used was adapted from a website whoose name I cannot recall, but I'm thankfull for the people over there for the help, as it is hard to do these things with my age.

The code is the following:

// Motor and sensor pins

#define engineR 11

#define inputR1 8

#define inputR2 9

#define engineL 13

#define inputL1 12

#define inputL2 10

// Sensor pins

#define sensorRR A0

#define sensorR A1

#define sensorRM A2

#define sensorLM A3

#define sensorL A4

#define sensorLL A5

QTRSensors qtr;

const int sensorCount = 6;

const int sensorPins[] = {A0, A1, A2, A3, A4, A5};

uint16_t sensorValues[sensorCount];

int P, D, I, previousError, PIDvalue, error;

int lsp, rsp, x;

int lfspeed = 400;

float Kp = 1.6; // Adjust this value based on experimentation

float Kd = 0.1; // Adjust this value based on experimentation

float Ki = 0.01; // Adjust this value based on experimentation

void setup() {

// Sensor setup

qtr.setTypeAnalog();

qtr.setSensorPins((const uint8_t[]){sensorRR, sensorR, sensorRM, sensorLM, sensorL, sensorLL}, sensorCount);

qtr.setEmitterPin(2);

// Calibration

delay(500);

for (uint16_t i = 0; i < 400; i++) {

qtr.calibrate();

}

// Motor and input pin setup

pinMode(engineR, OUTPUT);

pinMode(inputR1, OUTPUT);

pinMode(inputR2, OUTPUT);

pinMode(engineL, OUTPUT);

pinMode(inputL1, OUTPUT);

pinMode(inputL2, OUTPUT);

Serial.begin(9600);

}

void loop() {

linefollow();

}

void linefollow() {

int error = analogRead(sensorL) - analogRead(sensorR);

P = error;

I = I + error;

D = error - previousError;

PIDvalue = (Kp * P) + (Ki * I) + (Kd * D);

previousError = error;

lsp = lfspeed - PIDvalue;

rsp = lfspeed + PIDvalue;

if (lsp > 255) {

lsp = 255;

}

if (lsp < 0) {

lsp = 0;

}

if (rsp > 255) {

rsp = 255;

}

if (rsp < 0) {

rsp = 0;

}

Serial.println(rsp);

Serial.println(lsp);

digitalWrite(inputL1, HIGH);

digitalWrite(inputL2, LOW);

digitalWrite(inputR1, HIGH);

digitalWrite(inputR2, LOW);

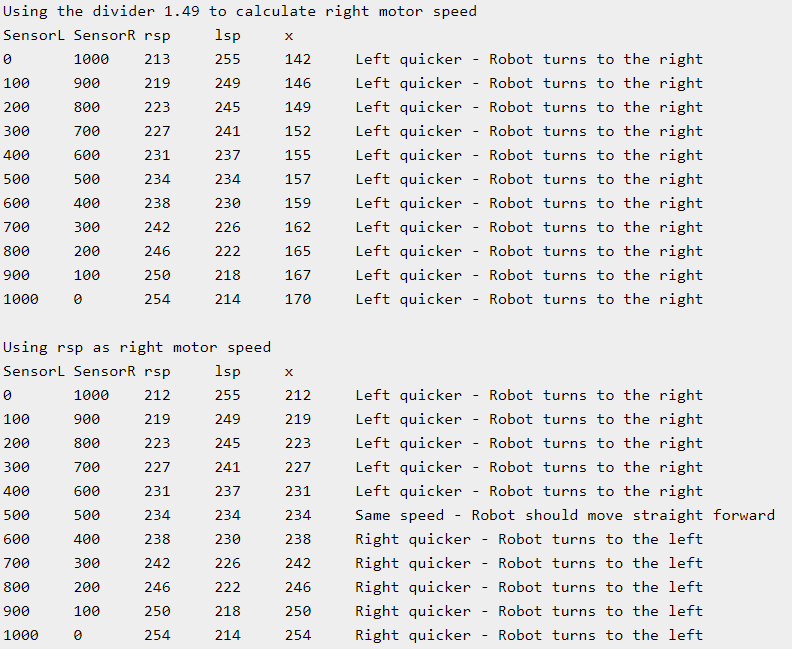

x = rsp/1,49;

analogWrite(engineR, x);

analogWrite(engineL, lsp);

}

I used an Arduino Mega, an L298n motor driver, a QTR8 sensor arry and two I belive 9 V batteries. The QTR Sensors library will be necessary.

I pray that the good samaritans of this forum can help help me, and I wish the best for their families.

Salutations, Robert