J-M-L:

WiFi is WiFi and electromagnetic laws are not likely to change anytime soon... hoping that the weak small antenna of your ESP will catch a signal in a potentially very "noisy" (electro-magnetically) environment or have reception for a WiFi or 4G signal is quite a strong bet...

The argument that it’s too late and that half baked / poor decisions are made but you need to stick to it is plain stupid (not a value judgment on you).

I see this often in students’ projects where they have made poor hardware choices early without exploring constraints and requirements and then don’t have the guts to take a step back when they realize it won’t work and try to find excuses.

You are learning to become a decision maker (bachelor level) and recognizing a dead end is part of a project’s course. You should embrace that learning and make it a part of your report.

I can tell you that when you’ll present your work to a panel they will give you a very hard time on this (or when a jury will evaluate your work if you don’t present in person).

You can either stay the course and explain that your ESP based WiFi solution will not work in real life (and explain what architecture would be needed and explain why you went that way because your work is about predictive maintenance, IOT, benefits of big data in maritime world and thus you went for an easy way to demonstrate data collection) or correct course and have a small wired bus (no need to go for CAN, the bus concept is what matters) and explain the system architecture of slave units collaboratively reporting their data on a bus to a master located where cellular signals is available(GPRS, satellite, 3G/4G/5G) which will be the one connected to the IOT server.

To your code - Have you tried your code? Does it work?

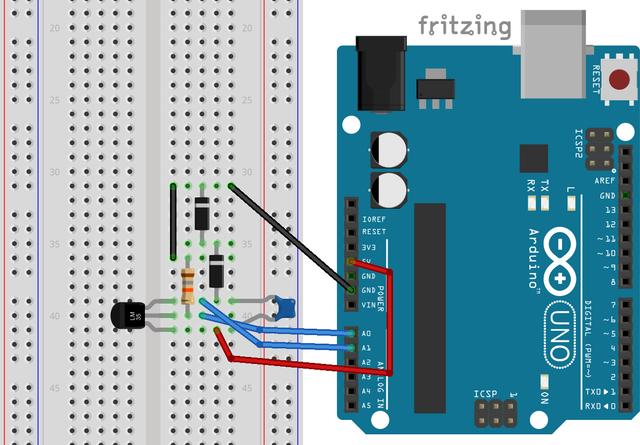

There are zillions blynk examples to capture a value and export it to blynk - so its a one minute work to change the two lines that read the values with analogRead if that’s what you want to do.

Have a look at the library's examples and start from there

for the blynk library i already used that link, i tried my best to gather all the informations , i didn't try it because as i said before my Esp and other sensors not yet delivered it's been already about 4 months because of covid-19 . So i only have to stick to fritzing and IDE. teachers know that already, and there was a lot of obstacles for all the students not only me.

i'm not trying to make excuses, i know that you're saying that for my sake, i really appreciate that. i failed to choose the right option because i lack knowledge and informations and i neglected the environment of the project.

Failure is an option here. If things are not failing, you’re not innovating enough. – Elon Musk

it's not that i don't admit it, but still that doesn't mean i didn't learn anything. i know it's stupid to stick to the dead end but we will never know until we do it by ourselves that's how i can learn to improve myself and grow up.

I said that i will stick to the wifi because it's already decided and i have to send the report today or tomorrow, i can only overcome that in my presentation and explain it without affecting my project, i have my way to convince the jury of my project, (it's a little stupid to attempt to fool my teachers but i can use this few knowledge to overcome the situation because my teachers lack knowledge in this field of arduino and IOT, i know their background they only know about mechanics).

Don't get me wrong i'm not a bad person or trying to lie to my teachers, but i have to be the lawyer for the patient, no matter what even if it's really the culprit i still have to defend him. it's all about using knowledge to get people's judgment to your side.

i'm not feeling good about what i attempt to do, but after i finish this matter i will correct my mistake and learn more about how to improve the project, because i want to prove myself to my own self.

Very sorry for disappointing you, and thank you for the help.

![]()

![]()

![]()