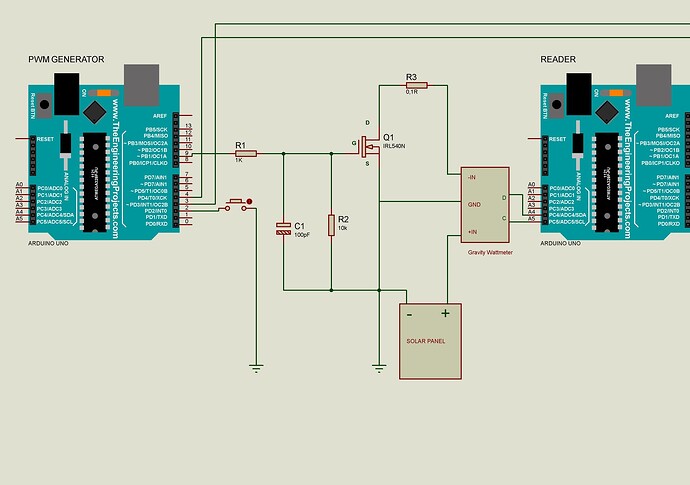

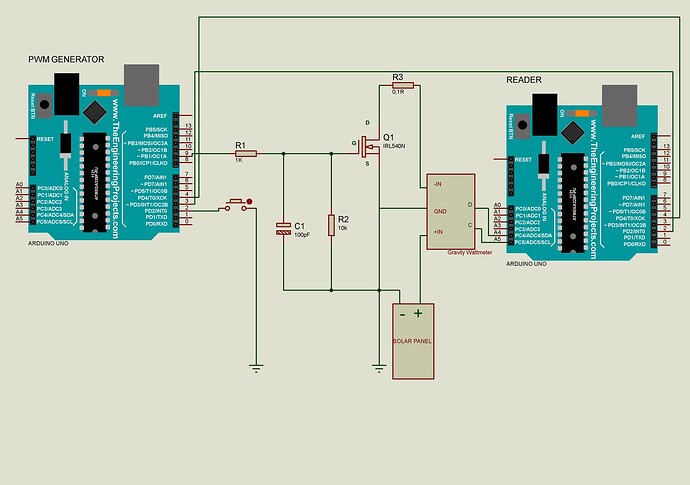

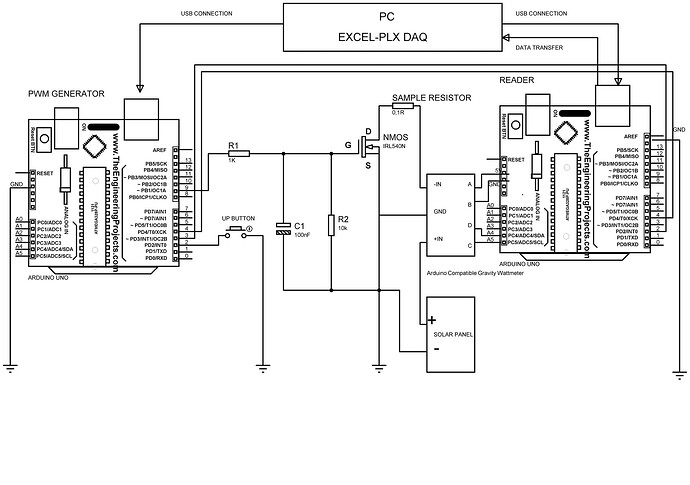

I have two Arduinos. The first Arduino provides a PWM signal to a MOSFET, incrementing the OCR1A register value step by step. I achieve this by continuously pressing a button connected to digital pin 2 within an if loop. The MOSFET adjusts the current level in a circuit accordingly. The second Arduino reads the current changes, voltage, and power using a wattmeter. I want to receive a reading on the second Arduino every time the first Arduino increments the OCR1A value. Only a button is connected to digital pin 2 on the first Arduino, and the digital pins 4 on both Arduinos are physically connected. What might be wrong with the code?

I don't understand how the interrupt function works completely. I received programming assistance from ChatGPT, but it keeps insisting that I can use pin 2, which is connected to a button, as an interrupt pin. This doesn't make sense to me. Pin 2 is internally built with a pull-up and constantly receives a low signal. How can I activate an interrupt triggered by a rising edge? I don't understand all of this. Please help.

#define Up 2 // Pin 2 teki artırma butonu

int stateUp; // Yukarı butonunun bilgisini tutacak değişken

const int stepPin = 4; //değeri bir daha değiştirilemez türde integer bir değişken

volatile bool stepTriggered = false; //Kesme işlevlerinde kullanılan değişkenler "volatile" olarak işaretlenir, çünkü bu değişkenlerin değerleri donanım tarafından değiştirilebilir ve bu değişiklikler hemen işlenmelidir./

void setup()

{

pinMode(Up, INPUT_PULLUP); // Up butonuna dahili pull-up uygulaması

pinMode(stepPin, OUTPUT);

digitalWrite(stepPin, LOW);

attachInterrupt(digitalPinToInterrupt(2), triggerStep, RISING);

DDRB |= (1 << DDB1) | (1 << DDB2); // Set ports

TCCR1A = (1 << COM1A1) | (1 << COM1B1) | (1 << WGM11); // Fast PWM mode

TCCR1B = (1 << WGM12) | (1 << WGM13) | (1 << CS10); // Fast PWM mode, no clock prescaling possible

OCR1A = 0; // Start PWM just below MOSFET turn on

ICR1 = 8191; // Set the number of PWM steps

Serial.begin(115200); // Start communication with serial monitor

}

void loop()

{ stateUp=digitalRead(Up);

if(stateUp==LOW){

OCR1A++;

delay(20);

Serial.println(OCR1A);}

if (stepTriggered)

{

stepTriggered = false;

digitalWrite(stepPin, HIGH);

delay(1);

digitalWrite(stepPin, LOW);

}

}

void triggerStep() {

// Adım sinyali kesme işlevi

stepTriggered = true;

}

#include <Wire.h>

#include "DFRobot_INA219.h"

DFRobot_INA219_IIC ina219(&Wire, INA219_I2C_ADDRESS4);

// Revise the following two paramters according to actual reading of the INA219 and the multimeter

// for linearly calibration

float ina219Reading_mA = 1000;

float extMeterReading_mA = 1000;

void setup(void)

{

Serial.begin(115200);

while(!Serial);

Serial.println();

while(ina219.begin() != true) {

Serial.println("INA219 begin faild");

delay(2000);}

//Linear calibration

ina219.linearCalibrate(/*The measured current before calibration*/ina219Reading_mA, /*The current measured by other current testers*/extMeterReading_mA);

Serial.println();

Serial.println("CLEARSHEET");

Serial.println("LABEL,Date,Time,Bus Voltage(V), Shunt Voltage(mV), Current(mA), Power(mW)");

}

void loop(void)

{if (digitalRead(4)==HIGH)

{Serial.print("DATA,DATE,TIME,");

Serial.print(ina219.getBusVoltage_V(), 2);

Serial.print(",");

Serial.print(ina219.getShuntVoltage_mV(), 3);

Serial.print(",");

Serial.print(ina219.getCurrent_mA(), 1);

Serial.print(",") ;

Serial.print(ina219.getPower_mW(), 1);

Serial.print(",");

Serial.println("");

delay(100);

}}