1/ 9v rechargable? ok but not while in circuit. - but see my final comment.

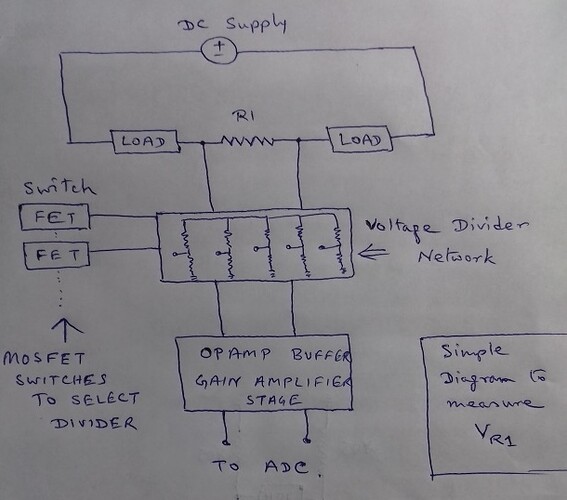

2/ OK - the pot divider and ground-based a/d idea. I'll have some fun here.

2 resistor chains to ground 4meg/50k - 0.1% per resistor - that's 0.4% worst case.

And about 90 x signal attenuation.

So now your signal goes from about 0.4mV fullscale at the resistance to be measured down to about 5uV fullscale at the ADS1115 ! one bit at 16 bit resolution with a 5v reference is 0.76mV - 150 times bigger!

0.4mV is hard enough!!

So you'd then need a precision preamp with a gain of at least 100000 times (10e5) to get a usable signa! level ( 0.5v) . And input offset of a few tens of pV.

And as for the tempco?! And we're getting well down into noise levels here.

You can't buy such an opamp.

Anywhere. ( Or am I wrong?)

And given your 0.1% divider chain resistors, the centre point could be off by 0.4% of the 200V divided by 90 - ie 200 / 90 x 0.4% - that's 9mV! multiply by your 'perfect' opamp gain of 10e5 and you get an offset of about 900 volts at it's output!

Calibrate that! that's about 2000 x bigger than the signal! You'd need resistors better than 1 part in a million to make this work! Vishay are good, but not as good as that! and 20ppm/C is a good tempco for a resistor! I've used 0.01% resistors, and they were expensive and nowhere near good enough for this!

And unless the 200v is accurate, as it's varied, so will the offset - big time! Better get a 1ppm 400v supply! Do the sums!

So buy a posh 24-bit sigma-delta a/d from AD, TI , LT etc - that's still not good enough!

Do some sums!

(daft idea, Raschemmel - you can't dig your way out of this problem with just a divider chain and a better a/d. I read a post of yours a while back in which you suggested technical detail gave a measure of the poster's competence - try your own medicine! Recommending a 16-bit a/d is hardly detail.)

blow the a/d - that's the easy bit. This is an analog problem.

A possible way might be to sit the whole measuring stuff including a/d at the 200v level and couple digitised signals via optos down to a ground based arduino, PC or whatever - that would work. hmmmm .

You'd need an isolated power supply of 12v and a few tens of mA sitting at the 200v level - but - hey - even a wallwart might be OK.

You could split that to give +/-6 round the floating resistor in question, and then you COULD use a 7650 opamp - no rail-rail stuff needed.

Rethink...........

Allan