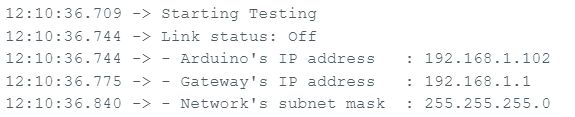

The code I'm using to test IP setup: (I pulled this from examples from zoomkat on here... though I do have some issues with setting the IP, gateway, and subnet, and getting the code to display them correctly, so the gateway and subnet are commented out (but they show in the serial monitor fine, from the last time I set them...))

#include <SPI.h>

#include <Ethernet.h>

byte mac[] = { 0xDE, 0xAD, 0xBE, 0xEF, 0xFE, 0xED }; //assign arduino mac address

byte ip[] = {192, 168, 1, 102}; // ip in lan assigned to arduino

//byte gateway[] = {192, 168, 1, 2}; // internet access via router

//byte subnet[] = {255, 255, 255, 0}; //subnet mask

void setup()

{

// put your setup code here, to run once:

delay(10000);

Serial.begin(9600); // start serial for output

Ethernet.begin(mac, ip);//, gateway);//, subnet); // initialize the Ethernet shield using the static IP address

Serial.println("Starting Testing");

}

void loop()

{

// optional, check link status

if (Ethernet.linkStatus() == LinkON)

Serial.println("Link status: On");

else

Serial.println("Link status: Off");

Serial.print("- Arduino's IP address : ");

Serial.println(Ethernet.localIP());

Serial.print("- Gateway's IP address : ");

Serial.println(Ethernet.gatewayIP());

Serial.print("- Network's subnet mask : ");

Serial.println(Ethernet.subnetMask());

//Serial.print("- DNS server's IP address: ");

//Serial.println(Ethernet.dnsServerIP());

delay(1000);

}

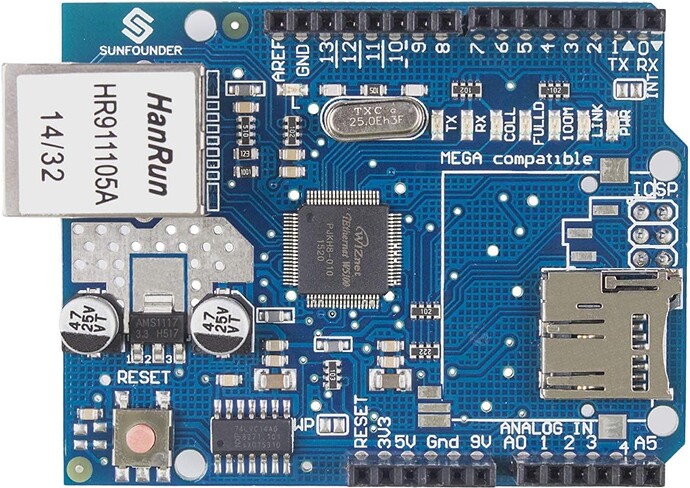

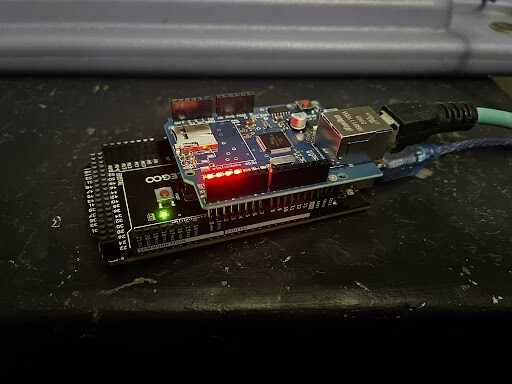

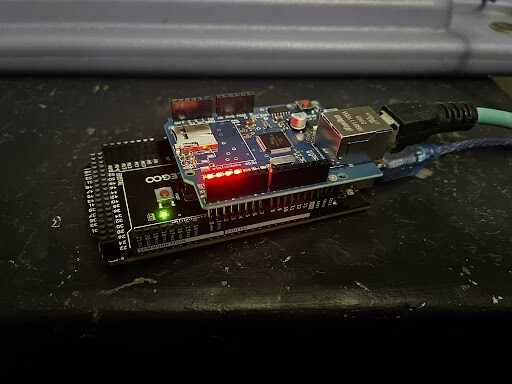

If I stack the shield on the Mega like normal:

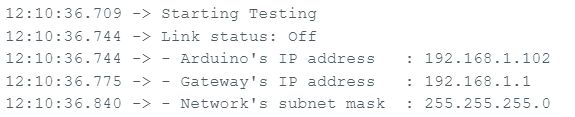

The program produces the correct info in the serial monitor:

However, when I move them to the breakout boards and wire them up in the following manner, I get bogus results.

Mega screw terminals to

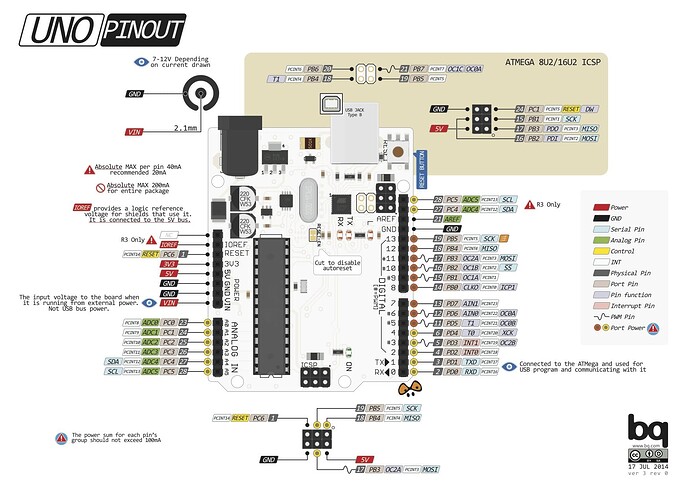

Uno shield screw terminals and ICSP pins

5V / GND / RST / 50....../ 51....../ 52

5V / GND / RST / MISO / MOSI / SCK

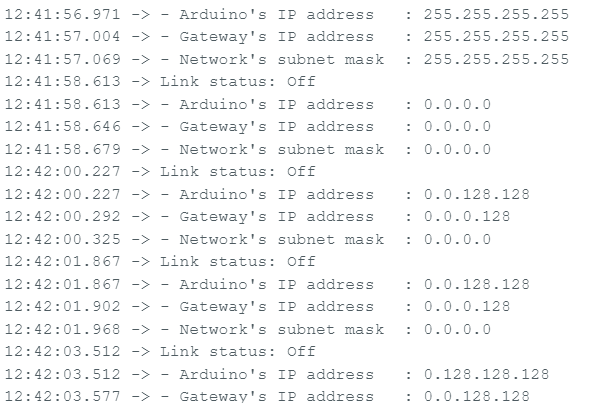

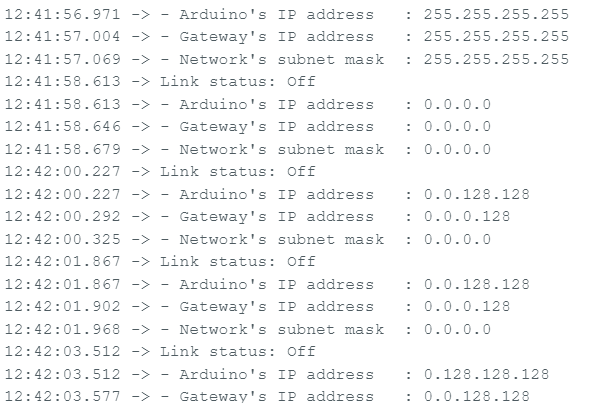

The program produces garbage like this:

I confirmed I have the shield ICSP pins correct. In that orientation L to R, T to B the pins would be:

RST........... / GND

13(SCK).... / 11(MOSI)

12(MISO)../ 5V

I verified by confirming the RST, GND, and 5V ICSP pins all have continuity to the screw terminals for the same.

Pulling the ICSP wires will change the random garbage I get in the serial monitor. For S&G's I swapped the MISO/MISO and the SCK wires all around. All garbage combinations.

Connected 3.3V between the breakouts just to test. No change.

But, if I put the shield directly back on the Mega.... it's all ok.

What am I missing?