Well here is my version of the arduino rover... which actually uses an iDuino, a Tamiya tracked vehicle kit (modded), a SRF-02 ultrasonic range finder, and some crappy code!

Here I will post some pics and videos, I won't post the code unless anyone is interested... its quite embarassing. ![]()

If you don't wish to view the progress pics and vids, here is the video at the end, of the latest version, doin its thing: - YouTube

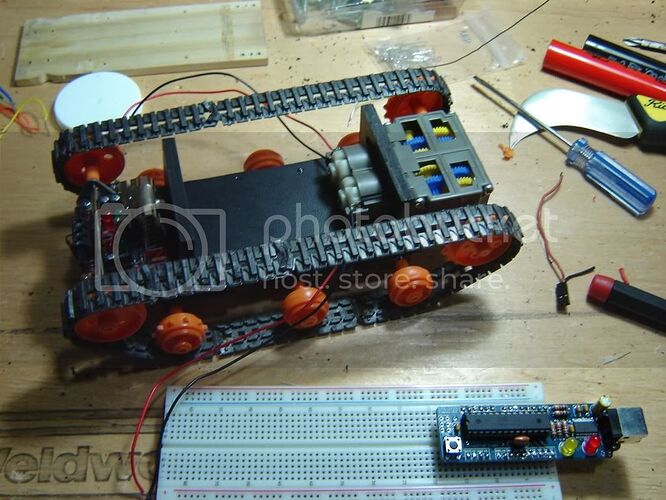

This pic was taken after I took the Tamiya tracked vehicle base out of the box and assembled it, haha look at it, what a POS! Only has one motor, so forward and backward... ordered a dual motor L/R independent gearbox, but it will be a while before I get that.

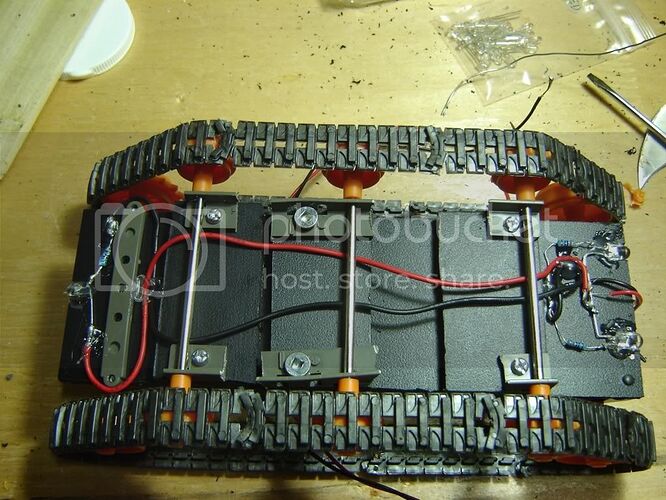

I put two breadboards together for lots of room, originally I planned on using the transistor + DPDT relay for motor direction and speed... that would have been pretty big if I ever set it up for the two motors.

Here is a video from that point of progress...

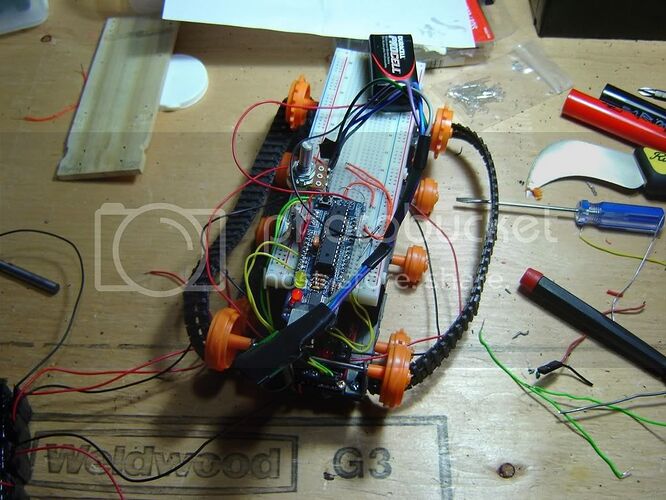

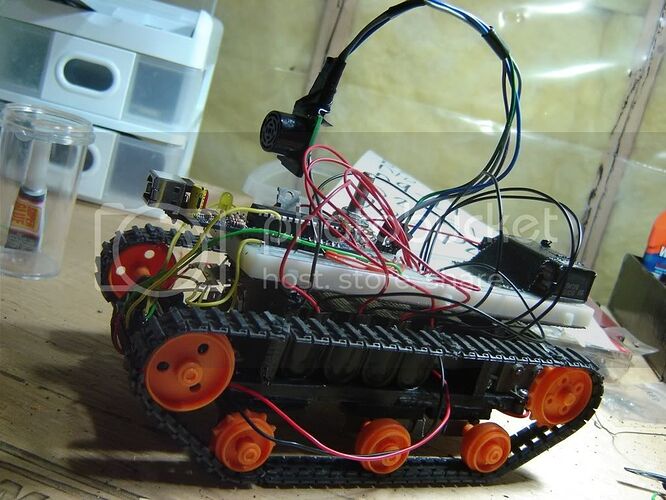

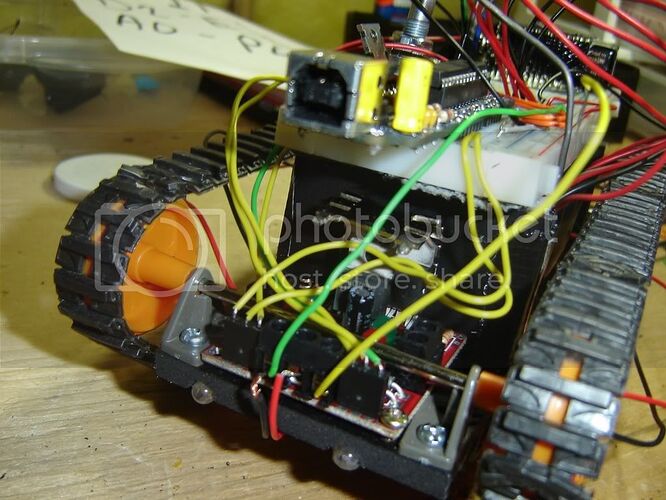

And heres a couple pictures after I mounted that stuff on the vehicle chassis, you can see the SRF-02 ultrasonic range finder laying on top in the first pic:

I did get the dual motor L/R independent gearbox installed in that chassis, and heres a video of that,

- YouTube - Ignore the music, youtube did something strange to the sound of that one, and it was all really distorted, so I randomly picked a song on the Youtube AudioSwap page... ugh... You will also notice a red square PCB on the back now, instead of the yellow DPDT relay, I decided to go with a L298 motor driver package instead because it was easy and readily available in 'kit form'.

Anyway I started having trouble with the tracks coming off on carpet when it was turning, and the chassis was limited by the fact that it was a simple piece of wood ![]()

So I set to work rebuilding it from scratch, using some lightweight material I found at work, cant figure out if its closer to wood or plastic... but it works!

Heres the old chassis sitting on top of the new...

Okay, I don't like how I have the sensor mounted, and I have this problem where the ultrasonic sensor won't quite pick up objects at certain angles, and it will run into the wall and flip itself over. So I devised a way around this, by creating a terribly ugly bumper on the front, hot glued together, which when pressed on turns a pin HIGH, the vehicle then backs away and scans for a new path.

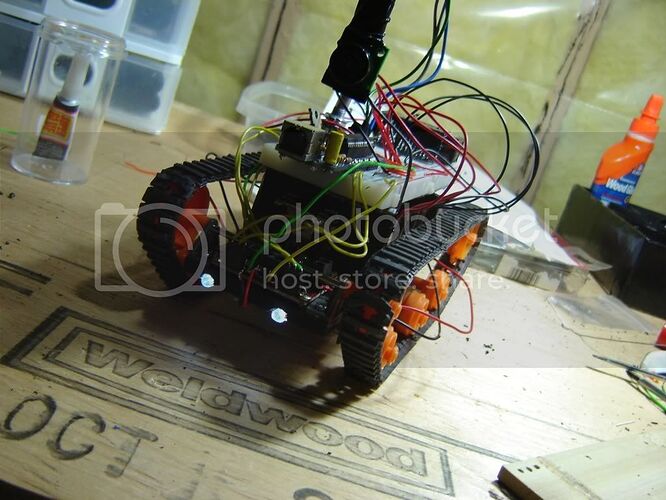

Heres some pics after that was added...

And finally, a video of the rover in its current state... don't mind the mess, im renovating that kitchen!

Future? Well, I plan on mounting some more range finders on it, possibly on a servo that can swivel the sensors around, or maybe even pan AND tilt... not sure. The whole reason it has the stupid bumper guard on it in the first place is because the ultrasonic range finder is stationary, and at angles it does not pick objects up properly... more sensors are definitely needed before I can remove the bumper guard switch....

Im open to criticism, this is my first real project... so I am not expecting much ![]()

Thanks for checkin it out ![]()