Good Morning.

I need an Active Photodetector for the following task.

Detect the change between blue, red and green bands that will be attached to the shaft of a moving engine.

Basically I will have an axis with several tracks in a blue/red/green sequence that is repeated throughout the circumference of the axis, these tracks have a very short length (less than an arc of 5 degrees of circumference on an axis of radius 2 cm = ~ 1.7mm) and are rotating at high angular speed. The sensor must be able to return the intensity of the band perpendicular to it at every instant and when it is in a position where there is a transition between bands of different colors it needs to be able to quickly return the interpolated values of these colors, that is when it is in a transition from a red to a green band the sensor needs to return a real-time signal that starts with a red spike and smoothly changes to a green spike.

In this way, it would be possible to identify the relative position of the sensor in relation to the axis tracks, which is the objective I intend to achieve.

Looking at catalog I came across the TCS34725 that is working for low speeds but with a precision a little far from what I need when detecting lane changes, this is also being caused by the low response speed of it that is in 2.4 ms.

So I'm looking for a sensor with enough features and reading speed to do this job.

In this case, my biggest problem is the accuracy of the reading, many times the TCS34725 returns me values of colors that are not close to it.

The speed I want to perform my next tests is something around 44 rpm.

I calculated that for an axis with 60 tracks each track will occupy an arc of 6 degrees, for each track the sensor will have to be able to perform 90 readings, so that it will be possible to draw a moving average with an offset set to 10, that is 90 readings we will have 9 valid values (which will be later processed in the program).

So I need a sensor that has a read speed of 0.25ms or 34KHz.

Or anything close to 1ms would be useful.

By precision I mean correct reading data, for example many times my current sensor is between green and red colors it ends up returning me a non-null value of blue.

In this video it is also possible to see a problem that I am also facing, which is these sudden drops in some values.

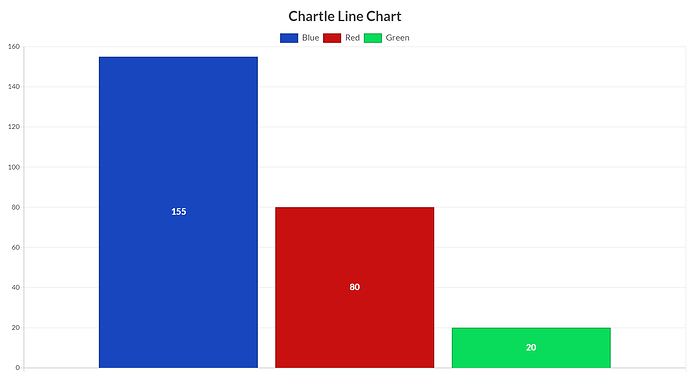

Correct result (Expected)

Wrong result (It is currently happening)