Howdy all.

Been struggling with this for a week now, any advice or direction would be appreciated. I have an inverted pendelum mechanical system with a motor atop spinning a decent moment of inertia - the angular acceleration of this reaction wheel should balance the inverted pendulum (think self balancing bicycle robot etc) . For this I am using a PID control to control overshoot/provide smoothing and an overall balance. My issue is that the brushed DC motor, having that mass/moment of interia on the shaft, has some degree of static friction (output of 0-40 / 255 does not move the motor). This has proven very troublesome to overcome with the PID.

I have approached the problem by simply providing a deadband of +-40 so that any output value >0 is increased by 40, and any <0 is decreased by 40. This results in violent twitching of the system about the setpoint - progressively larger and violent overshoots. My goal is balance like this video (03:40):

https://www.youtube.com/watch?v=4kfBEaTncjI

I am using the same motor and motor controller as him as well. Any thoughts? Thanks guys

Another note: I think this setup has some nasty noise coming from the motor leads or something it's very common for the system to, upon a very rapid change in speed or direction and therefore an increased line current, go crazy and flash randomly between -255, 255, and 0 and trip my Supply safeties.

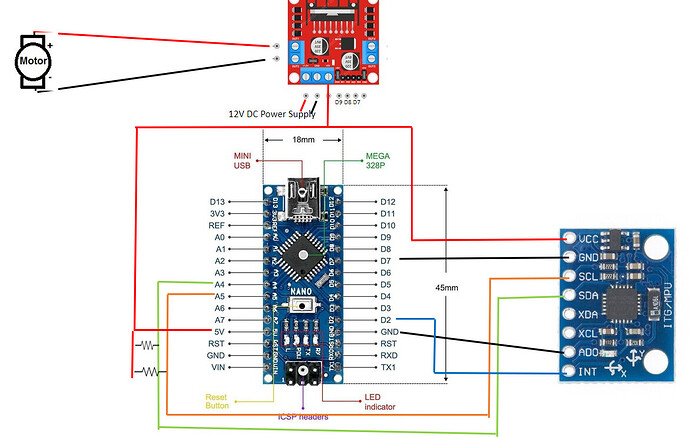

Here's a schematic of the wiring and my code:

Brushed (Geartrain) DC Motor Controlled by Ln298N motor driver

MPU6050 Gyro/Accel

Arduino Nano

12V DC Power Supply (Suppling 14V to overcome 2V drop by Ln298N)

#include "I2Cdev.h"

#include <PID_v1.h>

#include "MPU6050_6Axis_MotionApps20.h"

MPU6050 mpu;

bool dmpReady = false;

uint8_t mpuIntStatus;

uint8_t devStatus;

uint16_t packetSize;

uint16_t fifoCount;

uint8_t fifoBuffer[64];

Quaternion q;

VectorFloat gravity;

float ypr[3];

double setpoint = 178.5;

double Kp = 10;

double Kd = 0;

double Ki = 0;

double torqueOffset = 40;

double accelerometerAngle = 0;

const double alpha = 0.98;

const int IN1 = 8;

const int IN2 = 7;

const int EN1 = 9;

double input, output;

PID pid(&input, &output, &setpoint, Kp, Ki, Kd, DIRECT);

volatile bool mpuInterrupt = false;

void dmpDataReady()

{

mpuInterrupt = true;

}

void setup()

{

Serial.begin(115200);

Serial.println(F("Initializing I2C devices..."));

mpu.initialize();

Serial.println(F("Testing device connections..."));

Serial.println(mpu.testConnection() ? F("MPU6050 connection successful") : F("MPU6050 connection failed"));

devStatus = mpu.dmpInitialize();

mpu.setXGyroOffset(45);

mpu.setYGyroOffset(46);

mpu.setZGyroOffset(64);

mpu.setXAccelOffset(-1468);

mpu.setYAccelOffset(716);

mpu.setZAccelOffset(639);

if (devStatus == 0)

{

Serial.println(F("Enabling DMP..."));

mpu.setDMPEnabled(true);

Serial.println(F("Enabling interrupt detection (Arduino external interrupt 0)..."));

attachInterrupt(0, dmpDataReady, RISING);

mpuIntStatus = mpu.getIntStatus();

Serial.println(F("DMP ready! Waiting for first interrupt..."));

dmpReady = true;

packetSize = mpu.dmpGetFIFOPacketSize();

pid.SetMode(AUTOMATIC);

pid.SetSampleTime(1);

pid.SetOutputLimits(-255 + torqueOffset, 255 - torqueOffset);

}

else

{

Serial.print(F("DMP Initialization failed (code "));

Serial.print(devStatus);

Serial.println(F(")"));

}

pinMode(IN1, OUTPUT);

pinMode(IN2, OUTPUT);

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

}

double adjustedOutput = 0;

double lastPitch = 0;

void loop()

{

unsigned long currentMillis = millis();

if (!dmpReady)

return;

while (!mpuInterrupt && fifoCount < packetSize)

{

pid.Compute();

Serial.print(input);

Serial.print("\t");

Serial.print(output);

if (output > 0)

{

adjustedOutput = output + torqueOffset;

}

else

{

adjustedOutput = output - torqueOffset;

}

Serial.print("\t");

Serial.println(adjustedOutput);

if (input > 120 && input < 250)

{

if (adjustedOutput > 0)

Forward();

else if (adjustedOutput < 0)

Reverse();

}

else

{

adjustedOutput = 0;

Stop();

}

}

mpuInterrupt = false;

mpuIntStatus = mpu.getIntStatus();

fifoCount = mpu.getFIFOCount();

if ((mpuIntStatus & 0x10) || fifoCount == 1024)

{

mpu.resetFIFO();

Serial.println(F("FIFO overflow!"));

}

else if (mpuIntStatus & 0x02)

{

while (fifoCount < packetSize)

fifoCount = mpu.getFIFOCount();

mpu.getFIFOBytes(fifoBuffer, packetSize);

fifoCount -= packetSize;

mpu.dmpGetQuaternion(&q, fifoBuffer);

mpu.dmpGetGravity(&gravity, &q);

mpu.dmpGetYawPitchRoll(ypr, &q, &gravity);

input = ypr[1] * 180 / M_PI + 180;

}

//prevent motor from rapidly occilating between -255, 0, and 255 randomly once PID output calls for 255 or -255

if (currentMillis >= 1000)

{

if (abs(input - lastPitch) > 100.00)

{

while (true)

{

Stop();

}

}

}

lastPitch = input;

}

void Forward()

{

digitalWrite(IN1, HIGH);

digitalWrite(IN2, LOW);

analogWrite(EN1, adjustedOutput);

Serial.print("F");

}

void Reverse()

{

digitalWrite(IN1, LOW);

digitalWrite(IN2, HIGH);

analogWrite(EN1, adjustedOutput * -1);

Serial.print("R");

}

void Stop()

{

digitalWrite(IN1, LOW);

digitalWrite(IN2, LOW);

Serial.print("S");

}