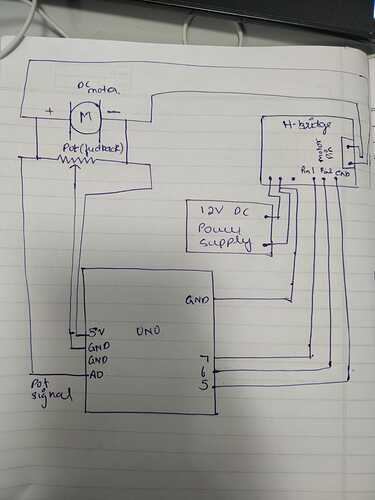

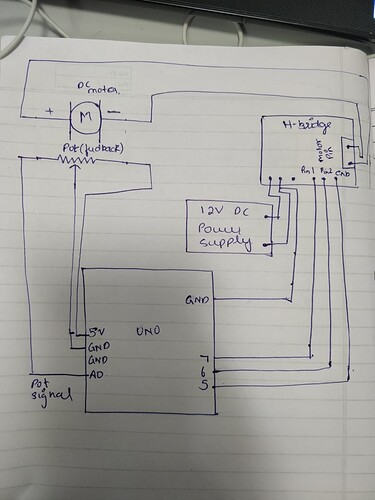

i need help with how to tune the parameters of PID . And can anyone verify if my code is correct. im trying to do the position control of a dc motor with pot acting as a feedback using arduino and PID.

thanks for your help in advance.

//PID constants

double kp = 2;

double ki =5;

double kd = 1;

unsigned long currentTime, previousTime;

double elapsedTime;

double error;

double lastError;

double input, output, setPoint;

double cumError, rateError;

int enB = 5;

int pin1 = 7;

int pin2 = 6;

int pot=A0;

int CurrentValue;

int DesiredValue;

void setup()

{

pinMode(enB, OUTPUT);

pinMode(pin1, OUTPUT);

pinMode(pin2, OUTPUT);

Serial.begin(9600);

}

void loop()

{

input = analogRead(A0);

output = computePID(input);

delay(100);

analogWrite(enB, output);

CurrentValue = analogRead(A0);

DesiredValue=600;

setPoint=DesiredValue;

if(DesiredValue>CurrentValue)//left

{

digitalWrite(pin1, LOW);

digitalWrite(pin2, HIGH);

analogWrite(enB,255);

}

if (DesiredValue< CurrentValue) //right

{

digitalWrite(pin1,HIGH);

digitalWrite(pin2, LOW);

analogWrite(enB,255);

}

if(abs(DesiredValue-CurrentValue)<20)

{

CurrentValue = analogRead(A0);

analogWrite(enB,255);

digitalWrite(pin1, LOW);

digitalWrite(pin2, LOW);

}

}

double computePID(double inp){

currentTime = millis(); //get current time

Serial.print(millis());

Serial.println(currentTime);

elapsedTime = (double)(currentTime - previousTime);

error = setPoint - inp;

cumError += error * elapsedTime;

rateError = (error - lastError)/elapsedTime;

double out = kp*error + ki*cumError + kd*rateError; //PID output

Serial.print(out);

lastError = error;

previousTime = currentTime;

return out;

}